Preparation method for spice used for cigarettes and application of spice

A technology for tobacco flavor and sweet fragrance, applied in the application, essential oil/spice, tobacco and other directions, can solve problems such as poor stability, and achieve the effects of ensuring consistency, improving comfort, and improving aroma quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

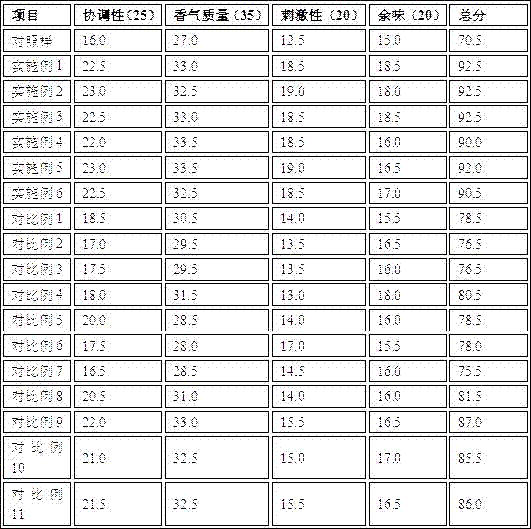

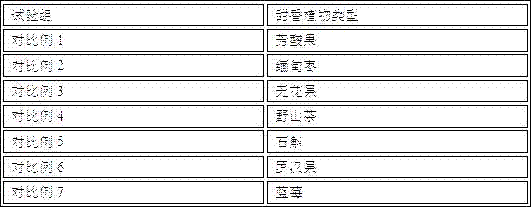

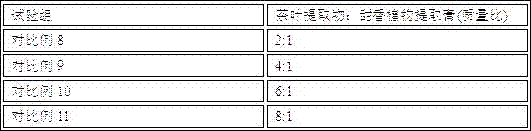

Examples

Embodiment 1

[0023] A preparation method of tobacco spices, the steps of the method are:

[0024] Step 1. Weigh 800g of Yunnan green tea and perform supercritical low-temperature extraction to obtain tea extract. The process conditions of supercritical low-temperature extraction are: extraction pressure 10Mpa, extraction temperature 10°C, separation temperature 60°C, extraction 3 times, total extraction time 20min;

[0025] Step 2. Weigh 200g of aromatic fruit and Burmese jujube, mix and mash, and then carry out solvent extraction. The process conditions of solvent extraction are: the extraction solvent is ethanol, the amount of solvent added is 1L, the extraction time is 12h, and the extraction temperature is 50°C. °C, after the extraction is completed, the solid-liquid separation is carried out, the collected liquid phase is concentrated under reduced pressure into a paste, and the sweet and fragrant plant extract paste is obtained;

[0026] Step 3. Mix the tea extract and the sweet and...

Embodiment 2

[0029] A preparation method of tobacco spices, the steps of the method are:

[0030] Step 1. Weigh 800g of Yunnan green tea and perform supercritical low-temperature extraction to obtain tea extract. The process conditions of supercritical low-temperature extraction are: extraction pressure 25Mpa, extraction temperature 30°C, separation temperature 50°C, extraction 2 times, total extraction time for 2h;

[0031] Step 2, take by weighing 200g of Myanmar jujube, fig, and wild camellia and mix and mash, then carry out solvent extraction. The process conditions of solvent extraction are: the extraction solvent is propylene glycol, and the amount of solvent added is 1L, the extraction time is 14h, and the extraction temperature is 50°C, solid-liquid separation after the extraction is completed, the collected liquid phase is concentrated under reduced pressure into a paste, and sweet and fragrant plant extract paste is obtained;

[0032] Step 3. Mix the tea extract and the sweet an...

Embodiment 3

[0035] A preparation method of tobacco spices, the steps of the method are:

[0036] Step 1. Weigh 800g of Yunnan green tea and perform supercritical low-temperature extraction to obtain tea extract. The process conditions of supercritical low-temperature extraction are: extraction pressure 40Mpa, extraction temperature 30°C, separation temperature 40°C, extraction once, total extraction time for 4h;

[0037] Step 2, take by weighing 100g each of Dendrobium, Luo Han Guo, wild camellia, and blueberry, mix and mash, then carry out solvent extraction. The process conditions of solvent extraction are: the extraction solvent is ethanol, the amount of solvent added is 1L, the extraction time is 12h, and the extraction temperature The temperature is 60°C. After the extraction is completed, the solid and liquid are separated, the collected liquid phase is concentrated under reduced pressure into a paste, and the sweet and fragrant plant extract paste is obtained;

[0038]Step 3. Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com