Solution for treating contact lens and contact lens packaging system

A contact lens and packaging system technology, which is applied in the direction of lens cleaning composition, disinfection, inorganic non-surface active cleaning composition, etc., which can solve the problems of rough surface, hard lens, and easy dry lens surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

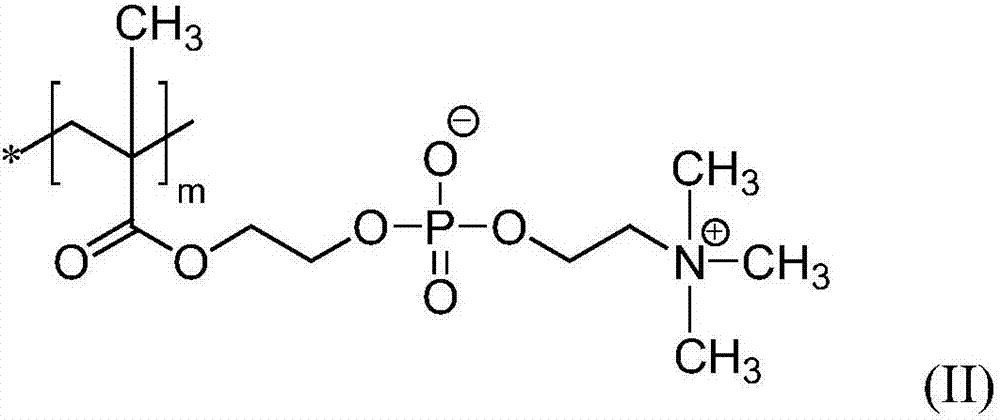

[0040] Experimental example 1: Preparation of homopolymer-poly[2-methacryloyloxyethylphosphorylcholine] (poly-MPC) with phosphorylcholine groups (Example 1A-1C):

[0041] In this experiment, 50g (0.169mole) of 2-methacryloyloxyethylphosphorylcholine (MPC) and 150mL of methanol (methanol) were added to a three-neck round-bottom flask, and the three-neck round-bottom flask was connected to reflux condensation reflux condenser. Nitrogen gas was introduced into the three-neck round bottom flask, and the MPC and methanol were stirred for 10 minutes until dissolved under the condition of being filled with nitrogen gas. Next, 0.25 g of azobisisobutyronitrile (AIBN) and 0.0398 g (0.509 mmole) of 2-mercaptoethanol were added and heated to 45° C. for 24 hours. AIBN is a polymerization initiator, which is connected to a carbon atom connected to a double bond in methacryloyloxyethyl of MPC to initiate free radical polymerization. 2-Mercaptoethanol is a polymer chain transfer agent (chai...

Embodiment 1A-1C

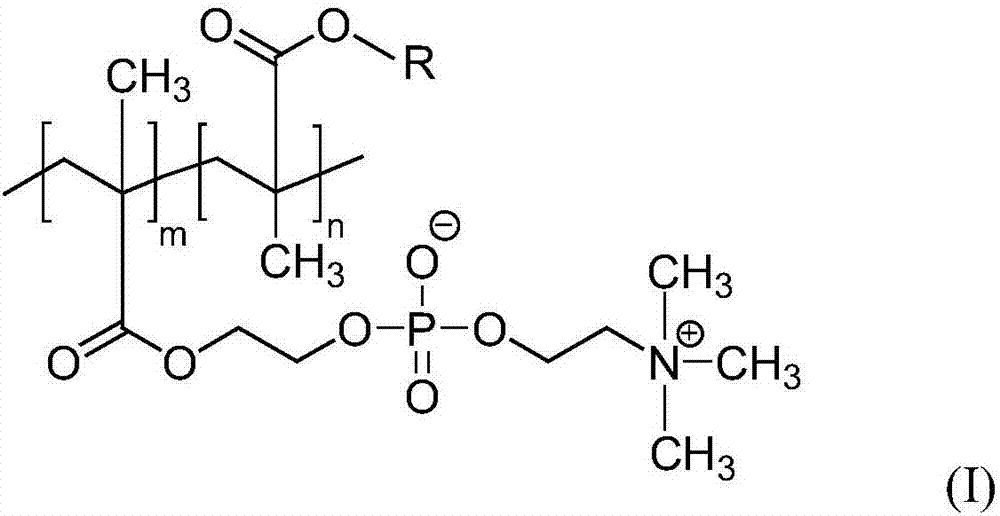

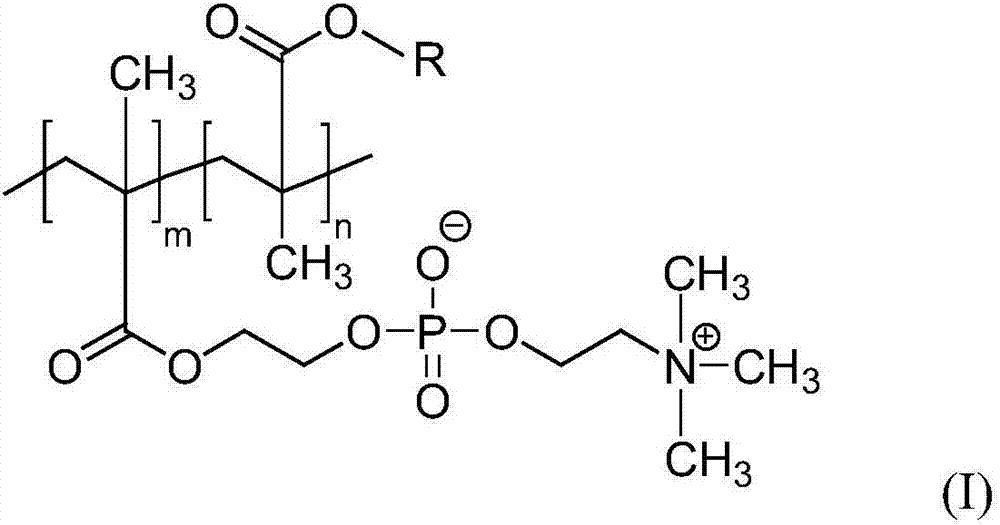

[0044] Examples 1A-1C have the structure of formula (II):

[0045]

[0046] In formula (II), m is a positive integer; and * is the starting point of the polymerization reaction, that is, the position where AIBN is connected.

experiment example 2

[0047] Experimental Example 2: Preparation of Copolymers with Phosphocholine Groups (Example 2A-2D):

[0048] The above method is also used for the preparation of the MPC copolymer, but different types of hydroxyalkyl methacrylate (hydroxyalkyl methacrylate) monomers are used for polymerization, and the amount of each reactant used is different. In detail, the preparation of MPC copolymer comprises adding 48g (0.163mole) of MPC, 12g (0.092mole) of hydroxyethyl methacrylate (2-hydroxyethyl methacrylate, HEMA) and 250mL of methanol into a three-neck round bottom flask , while the three-necked round-bottom flask was connected to a reflux condenser. Nitrogen was introduced into the three-necked round bottom flask, and the MPC, HEMA and methanol were stirred for 10 minutes under the condition of being filled with nitrogen until they were dissolved. Next, add 0.295g of AIBN and different amounts of 2-mercaptoethanol, respectively 0.932g (0.012mole), 0.2343g (3mmole), or 0.0469 (0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com