Submarine gas-liquid-solid multiphase fluidization separating method for natural gas hydrate

A hydrate and multiphase flow technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem of sand and hydrate clogging the energy consumption cost of methane stable production, which has not been effectively solved, and is very difficult to solve. Difficult to steady-state transportation and other problems, to achieve the effect of effective utilization, simple structure, flexible and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better illustrate the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, and Not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

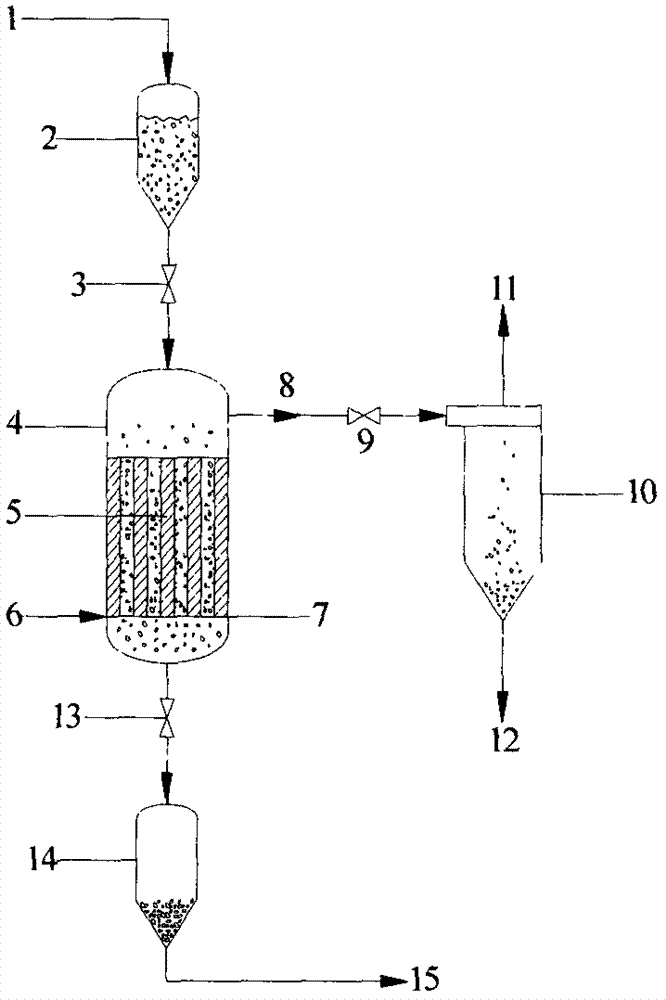

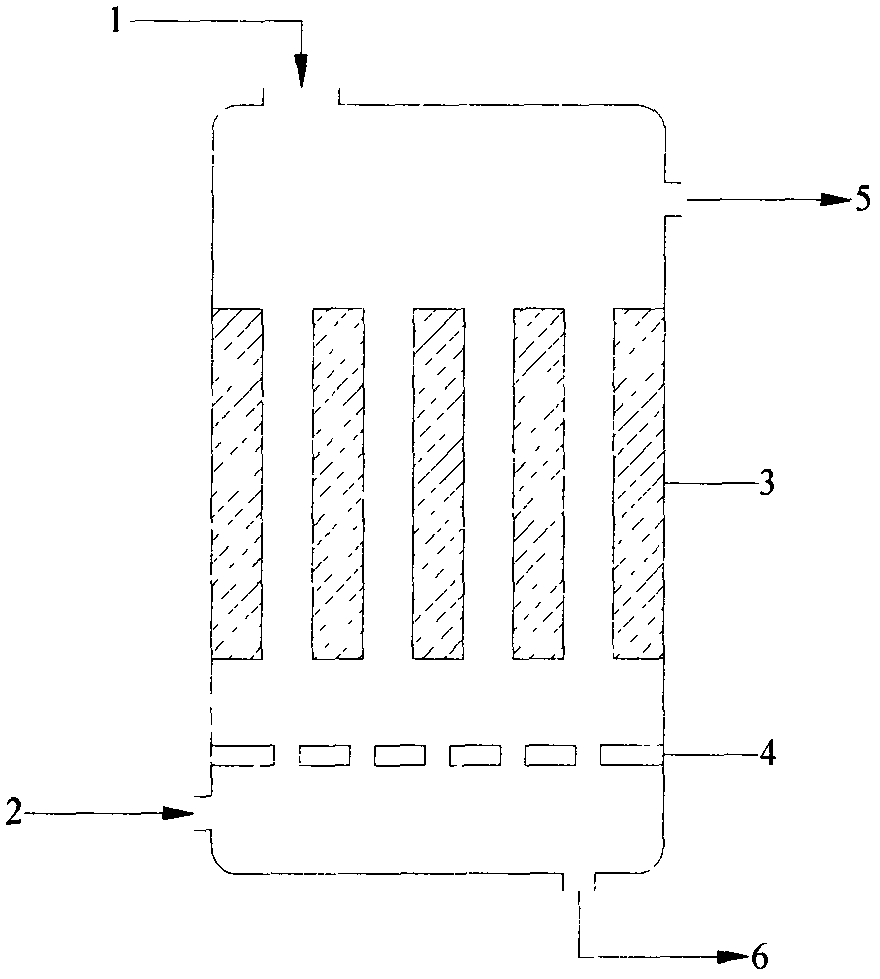

[0021] Such as figure 1As shown, the equipment in a method for gas-liquid-solid multiphase fluidized separation of natural gas hydrate seabed proposed by the specific implementation example of the present invention mainly includes a fluidized bed (4), a feed lock hopper (2), a cyclone separation device (10), sand lock bucket (14), gas distribution plate (7), heating plate (5), feed gate valve (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com