Peanut drying equipment

A technology for drying equipment and peanuts, applied in food processing, food science, application, etc., can solve the problems of poor drying effect, achieve good drying effect, small heat loss, and increase the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

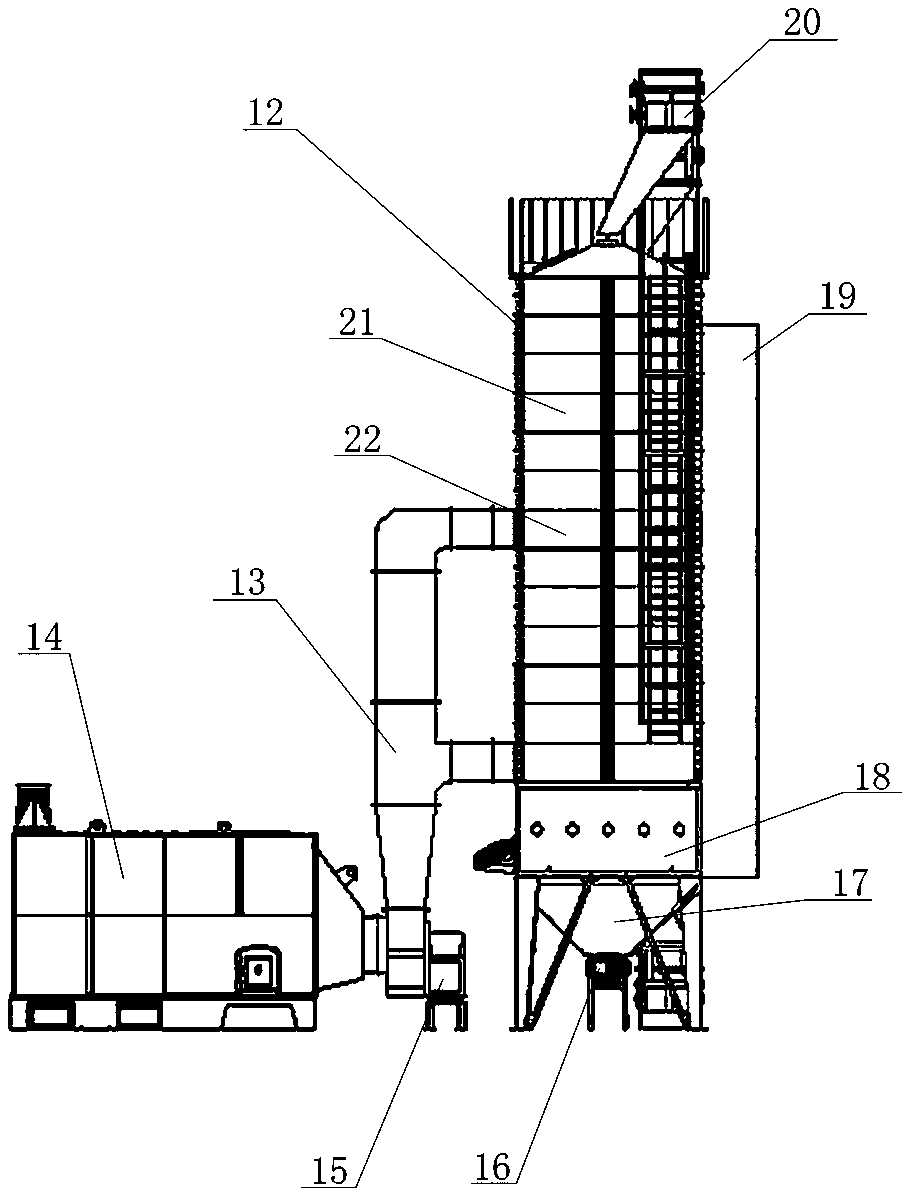

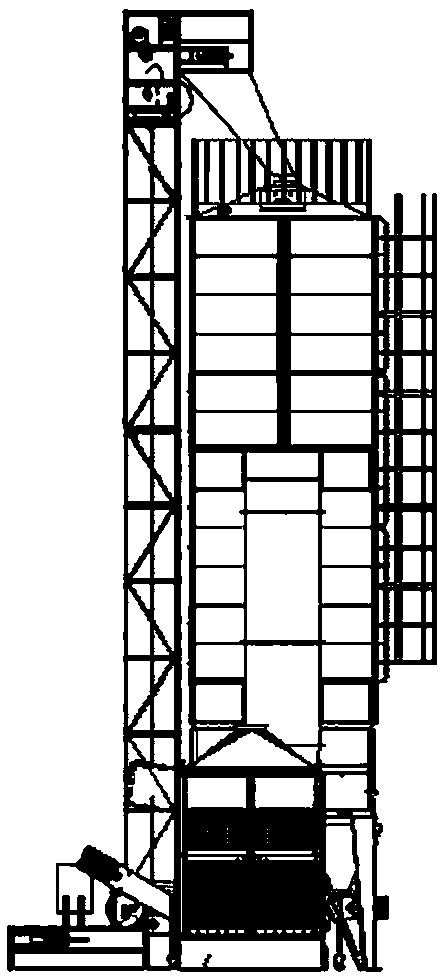

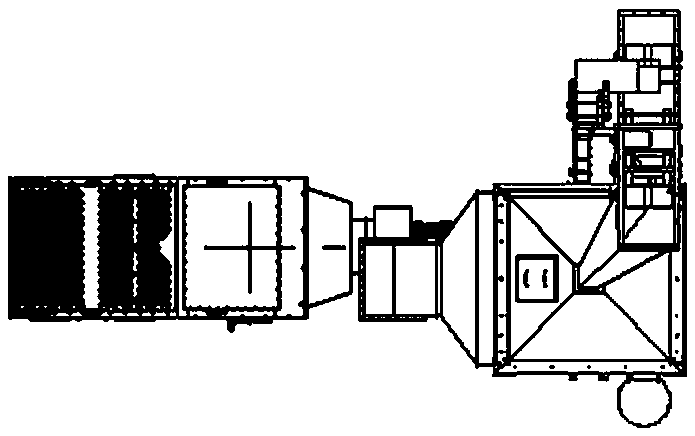

[0036] refer to Figure 1 to Figure 10 , the present invention it comprises a tower dryer 12;

[0037] The top of the tower dryer 12 is provided with a feed port corresponding to the discharge port of the elevator 20; the bottom of the tower dryer 12 is provided with a grain discharge chamber 18, and the grain discharge chamber 18 passes through the bottom. The belt conveyor 16 at the bottom of the bin at the end and the filling port of the hoist 20 communicate with each other correspondingly;

[0038] The middle part of the tower dryer 12 is provided with a slowing section 21 and a drying section 22 which communicate with each other from top to bottom; the slowing section 21 communicates with the feed inlet at the top of the tower dryer 12; the The drying section 22 communicates with the grain discharge chamber 18 at the bottom of the tower dryer 12; the inside of the drying section 22 is provided with an intake angle box 24 and an exhaust angle box 23 corresponding to each ...

Embodiment 2

[0046] The requirements for the material of the air inlet corner box of the peanut drying equipment are relatively high, and the present invention selects plastic composite materials, specifically,

[0047] The air intake corner box material is prepared according to the following process:

[0048] Take 100 parts of polycarbonate, 70 parts of polyphenylene ether resin, 20 parts of phthalic anhydride, 12 parts of glyceryl tristearate, 8 parts of polyglycolic acid, 6 parts of polyethylene wax and 2,2' - 1 part of methylenebis-(4-methyl-6-tert-butylphenol), mixed, stirred at 1000 rpm for 15 minutes, then put into an internal mixer, and mixed at 90°C for 5 minutes to obtain material A;

[0049] Add diatomaceous earth, borax and sepiolite to the ball mill in a weight ratio of 2:1:1, grind to a mixture with a particle size of 3um, then place it at 600°C for 30min, take it out, and cool it down to room temperature naturally. get material B;

[0050] Put material A, material B, silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com