Method for preparing foam metal through freeze drawing technology

A foam metal and process technology, applied in the field of new metal material preparation, can solve the problems of complex preparation process, high energy consumption, low efficiency, etc., and achieve the effects of large internal surface area, high porosity, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of method that adopts frozen drawing process to prepare foamed metal, its concrete process of preparing foamed metal is as follows:

[0025] Mix 3.5 kg of metal aluminum powder with a particle size of 50-100 μm, 0.35 kg of polyacrylamide, and 10 kg of water, and place it in a container, then add 1.5 kg of metal aluminum short fibers with a length of 0.3-0.5 mm, and continue stirring for 22 minutes. Take out the stirrer to form a viscous fluid with a viscosity of 2000cp, and deposit the viscous fluid pressurized spinneret in a mold cooled by liquid nitrogen to form a medium and fluffy foam; then place it in a box-type resistance furnace and heat up to Sinter at 80°C lower than the melting point, keep warm for 20 minutes, and cool with the furnace to obtain porous metal foam.

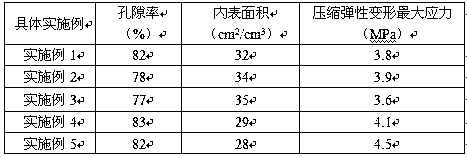

[0026] To the porous metal foam that embodiment 1 obtains, test its porosity and internal surface area, the data obtained are as shown in table 1;

[0027] For the porous metal foam obtaine...

Embodiment 2

[0029] A kind of method that adopts frozen drawing process to prepare foamed metal, its concrete process of preparing foamed metal is as follows:

[0030] Mix 3.2 kg of metal nickel powder with a particle size of 50-100 μm, 0.30 kg of gelatinized starch, and 10 kg of water, and place it in a container, then add 1.7 kg of metal nickel short fibers with a length of 0.3-0.5 mm, continue stirring for 20 minutes, and take out Stirrer, forming a viscous fluid with a viscosity of 3000cp, depositing the viscous fluid pressurized spinneret in a mold cooled by liquid nitrogen to form a medium and fluffy foam; then place it in a box-type resistance furnace and heat up to a low temperature Carry out sintering at the melting point of 100°C, keep warm for 20 minutes, and cool with the furnace to obtain porous metal foam.

[0031] To the porous metal foam that embodiment 2 obtains, test its porosity and internal surface area, the data obtained are as shown in table 1;

[0032] For the porou...

Embodiment 3

[0034] A kind of method that adopts frozen drawing process to prepare foamed metal, its concrete process of preparing foamed metal is as follows:

[0035] Mix 3.7kg of metal copper powder with a particle size of 50-100μm, 0.32kg of xanthan gum and 10kg of water, put them in a container, then add 1.8kg of metal copper short fibers with a length of 0.3-0.5mm, and continue stirring for 25 minutes. Take out the stirrer to form a viscous fluid with a viscosity of 2500cp, and deposit the viscous fluid pressurized spinneret in a mold cooled by liquid nitrogen to form a medium and fluffy foam; then place it in a box-type resistance furnace and heat up to Sinter at 60°C lower than the melting point, keep warm for 10 minutes, and cool with the furnace to obtain porous metal foam.

[0036]The porous metal foam that embodiment 3 obtains, tests its porosity and inner surface area, and the data obtained are as shown in table 1;

[0037] For the porous metal foam obtained in Example 3, comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com