Unit module for automatically detecting mold steel

A unit module, automatic detection technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of difficult mold batch industrial production, unstable inspection quality, low work efficiency, etc., to achieve batch industrial production, realize The effect of unmanned production and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

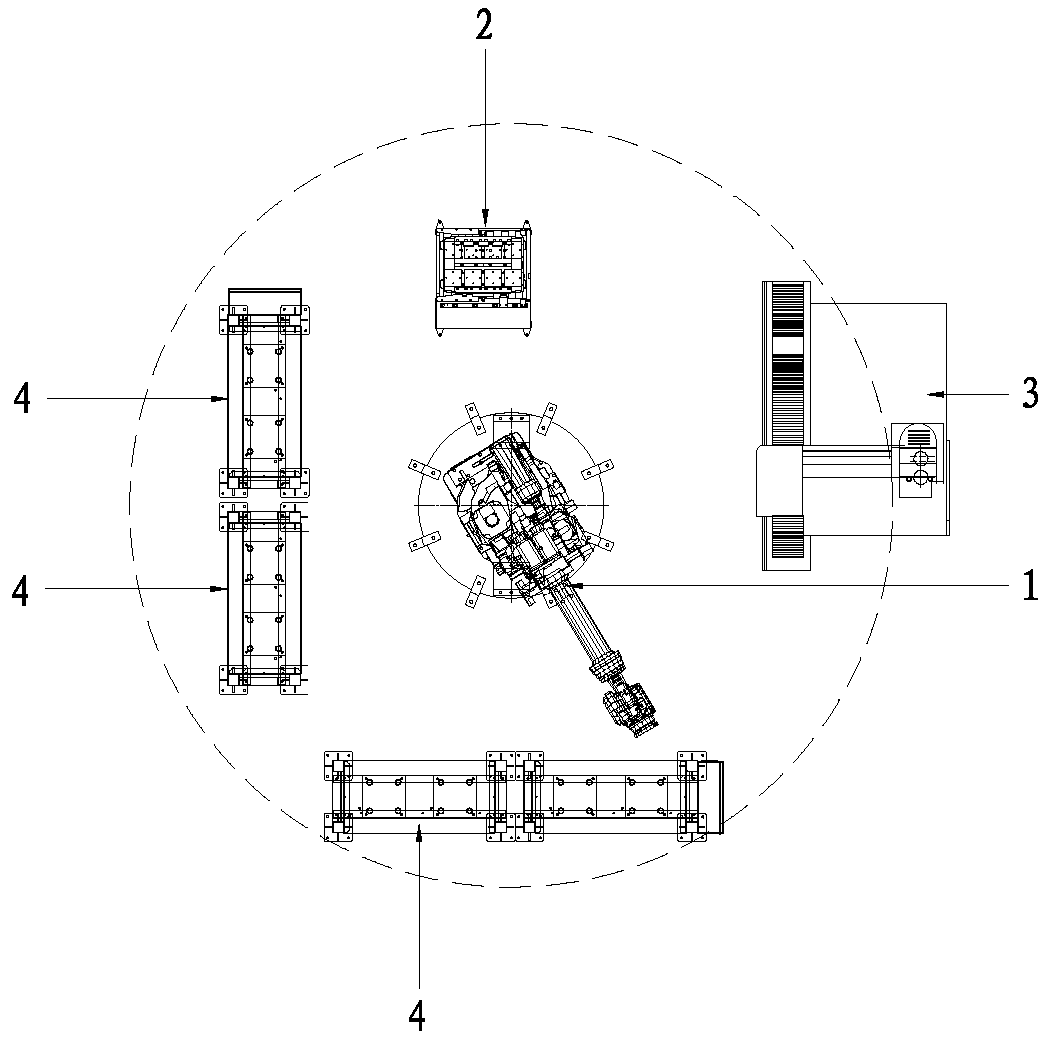

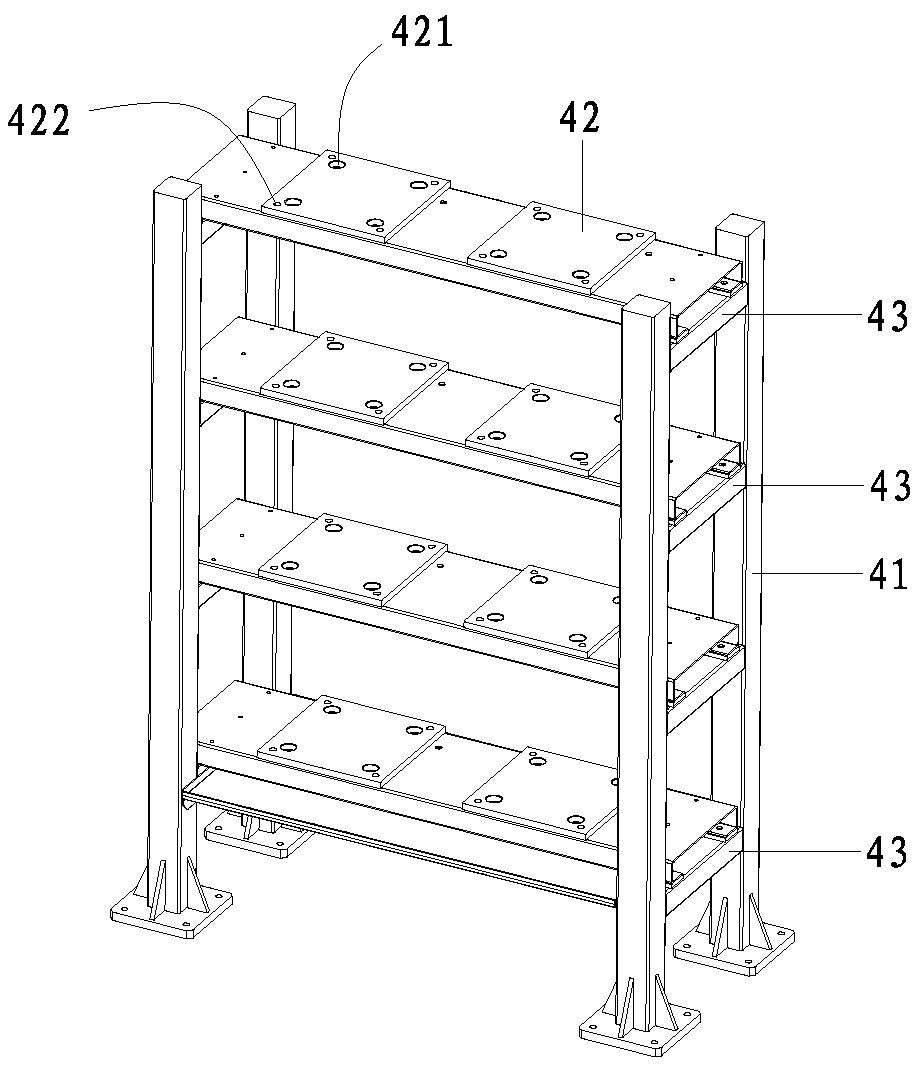

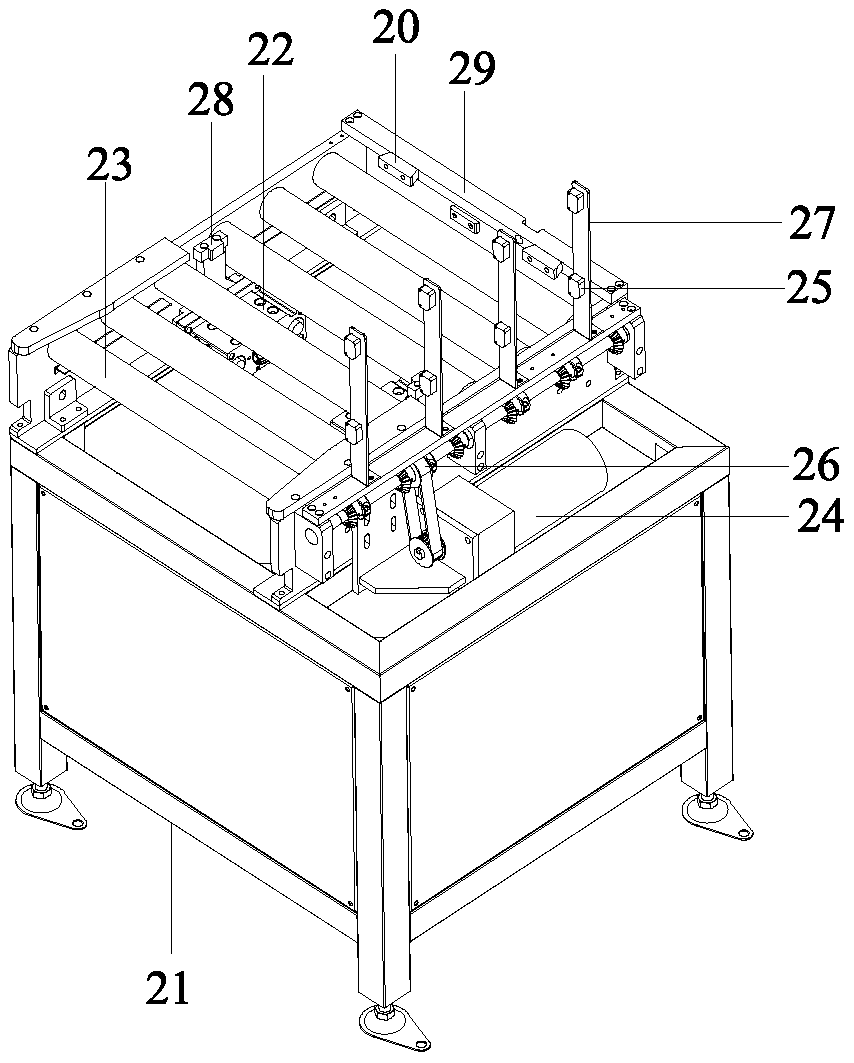

[0014] see figure 1 , figure 2 and image 3 , a mold steel automatic detection unit module provided in this embodiment, which includes a manipulator 1, a docking transfer station 2, a three-dimensional measuring machine 3 and a steel material placement frame 4, the docking transfer station 2, a three-dimensional measuring machine 3 And the steel material placement frame 4 is distributed on the peripheral position of this manipulator 1 with the manipulator 1 as the center of circle; The steel material placement frame 4 includes a support 41 and a standard placement seat 42, and the support 41 is arranged in sequence from top to bottom. There are a plurality of layered plates 43, and the standard placement seat 42 is arranged on the upper surface of the layered plate 43; the outline of the standard placement seat 42 is a square, and the four corners of the standard placement seat 42 are respectively provided with There is a steel positioning hole 421 and a mounting hole 422 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com