A-bit surplus solid oxide fuel cell cathode material as well as preparation method and application thereof

A fuel cell cathode and solid oxide technology, which is applied in solid electrolyte fuel cells, battery electrodes, chemical instruments and methods, etc., can solve the problems of electrode polarization impedance increasing cathode polarization impedance and reducing electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

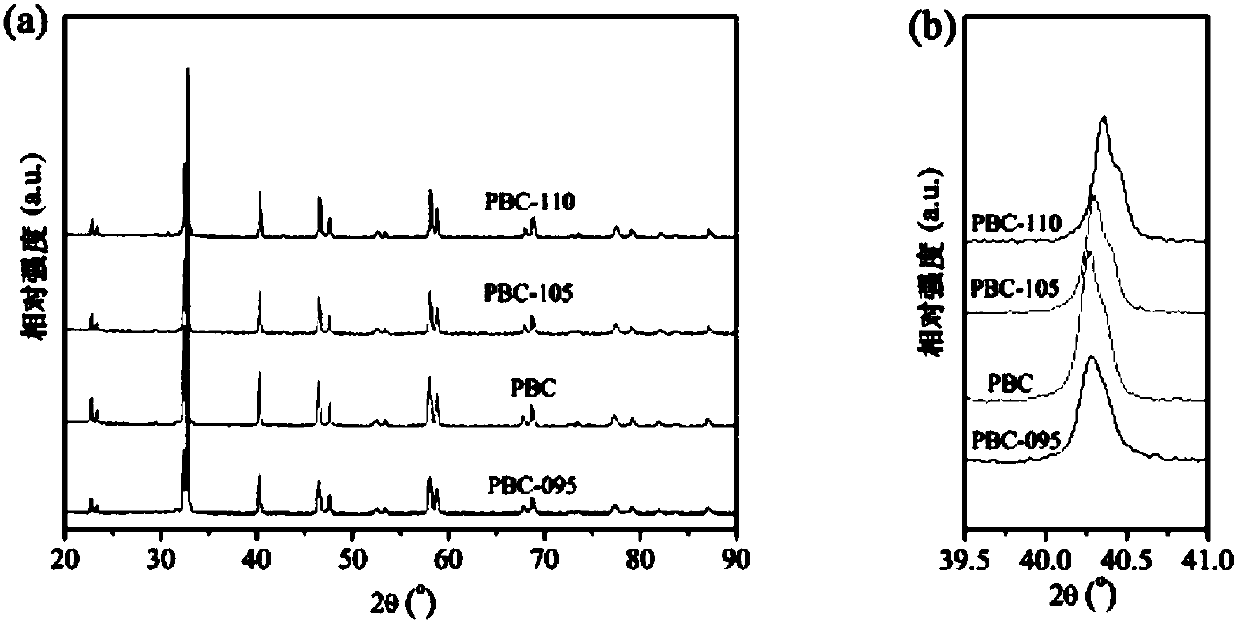

[0062] This embodiment provides a kind of cathode material Pr of above-mentioned medium and low temperature solid oxide fuel cell 1.05 BaCo 2 o 6-δ The preparation method, the specific steps are as follows: Weigh 5.7096 g of praseodymium nitrate, 3.2668 g of barium nitrate, 7.2758 g of cobalt nitrate, add a small amount of deionized water to dissolve. Weigh 15 g of ethylenediamine tetraacetic acid and 21 g of citric acid hydrate as a complexing agent and dissolve them in deionized water at a molar ratio of ethylenediaminetetraacetic acid: citric acid hydrate: total metal ions of 1:2:1. After adding the complexing agent-dissolved solution to the metal ion-dissolved solution, an appropriate amount of ammonia water is added dropwise to bring the pH of the solution to 7, and then the water is completely evaporated under magnetic stirring conditions to obtain a gel-like substance. The gel-like substance was calcined in an oven at 250 °C for 5 h to obtain the desired foamy precurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com