Mould-proof flame retardant polyethylene cable material

A technology of flame-retardant polyethylene and cable materials, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor resistance to mold and bacteria, decreased performance of antibacterial cable materials, and insignificant anti-mold functions. Effects of reducing loss, increasing load capacity, and increasing effective load area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

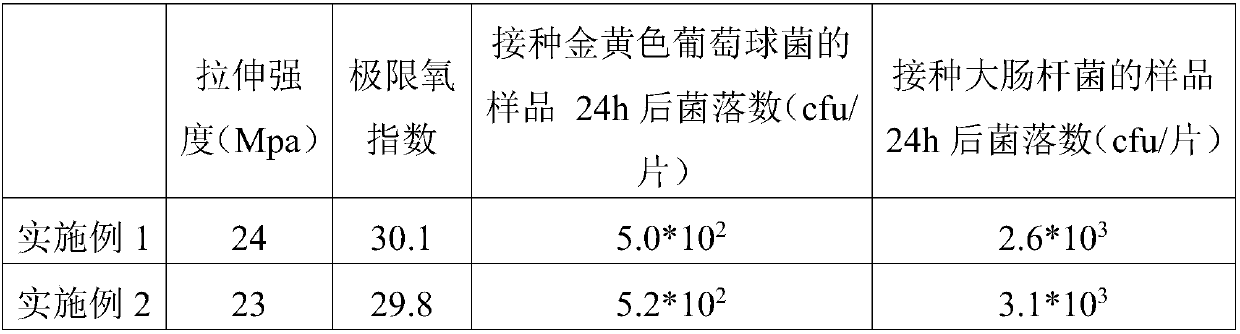

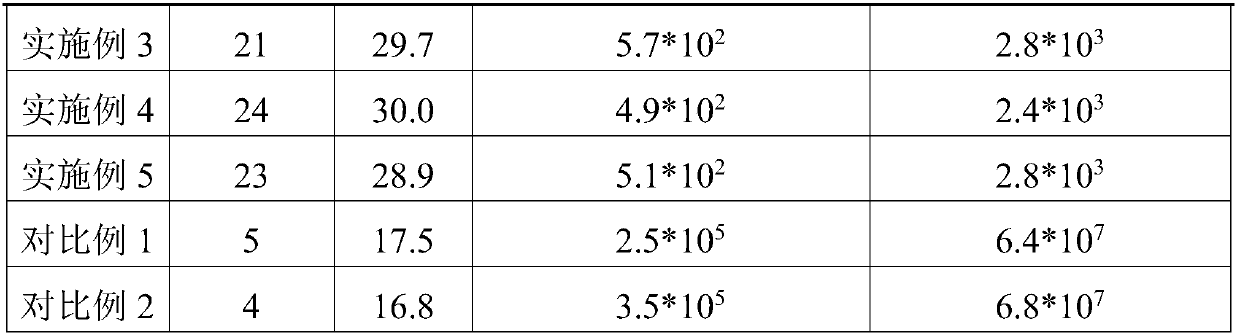

Examples

Embodiment 1

[0031] A mildew-resistant flame-retardant polyethylene cable material, comprising the following materials in parts by weight: 110 parts of high-density polyethylene resin, 70 parts of linear low-density polyethylene resin, 6 parts of carbon black, 30 parts of hydroxyphenylphosphorylacetic acid, titanium dioxide 2 parts, 2 parts of nano silver material, 23 parts of zeolite, 0.8 part of stearic acid.

[0032] The preparation method of the above-mentioned anti-mold flame-retardant polyethylene cable material comprises the following steps:

[0033] (1) Modification of compound antibacterial agent

[0034] Take by mass ratio polyethylene glycol: titanium dioxide powder: nano-silver material = 10:1:1, uniformly disperse titanium dioxide and nano-silver material in the aqueous solution of polyethylene glycol, evaporate the water under the condition of constant stirring, Obtain titanium dioxide and nano-silver materials coated with polyethylene glycol;

[0035] (2) Zeolite pretreatm...

Embodiment 2

[0040] A mildew-resistant flame-retardant polyethylene cable material, comprising the following materials in parts by weight: 100 parts of high-density polyethylene resin, 65 parts of linear low-density polyethylene resin, 5 parts of carbon black, 25 parts of hydroxyphenylphosphorylacetic acid, titanium dioxide 1 part, 1 part of nano silver material, 22 parts of zeolite, 0.2 part of calcium stearate, 0.3 part of dilauryl thiodipropionate.

[0041] The preparation method of the above-mentioned anti-mold flame-retardant polyethylene cable material comprises the following steps:

[0042] (1) Modification of compound antibacterial agent

[0043] Take by mass ratio polyethylene glycol: titanium dioxide powder: nano-silver material = 10:1:1, uniformly disperse titanium dioxide and nano-silver material in the aqueous solution of polyethylene glycol, evaporate the water under the condition of constant stirring, Obtain titanium dioxide and nano-silver materials coated with polyethylen...

Embodiment 3

[0049] A mildew-resistant flame-retardant polyethylene cable material, comprising the following materials in parts by weight: 115 parts of high-density polyethylene resin, 78 parts of linear low-density polyethylene resin, 7 parts of carbon black, 40 parts of decabromodiphenylethane, 2.5 parts of titanium dioxide, 2.5 parts of nano-silver material, 25 parts of zeolite, 0.5 parts of zinc stearate, bis(1-octyloxy-2,2,6,6-tetramethyl-4-piperidinyl) sebacic acid 0.5 part of ester.

[0050] The preparation method of the above-mentioned anti-mold flame-retardant polyethylene cable material comprises the following steps:

[0051] (1) Modification of compound antibacterial agent

[0052] Take by mass ratio polyethylene glycol: titanium dioxide powder: nano-silver material = 10:1:1, uniformly disperse titanium dioxide and nano-silver material in the aqueous solution of polyethylene glycol, evaporate the water under the condition of constant stirring, Obtain titanium dioxide and nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com