Preparation method of sugarcane grape composite fruit wine

A technology for compounding fruit wine and sugar cane, which is applied in the preparation of alcoholic beverages, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of single nutrient composition of sugar cane fruit wine and complicated preparation process, and achieves good product stability, color and luster. Clear and transparent, the effect of maintaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

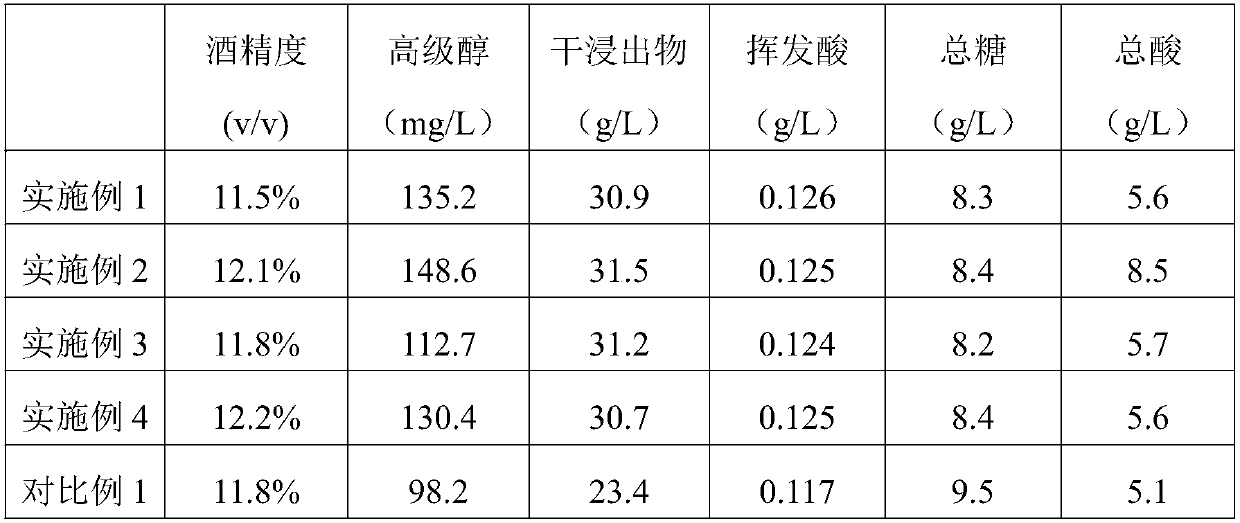

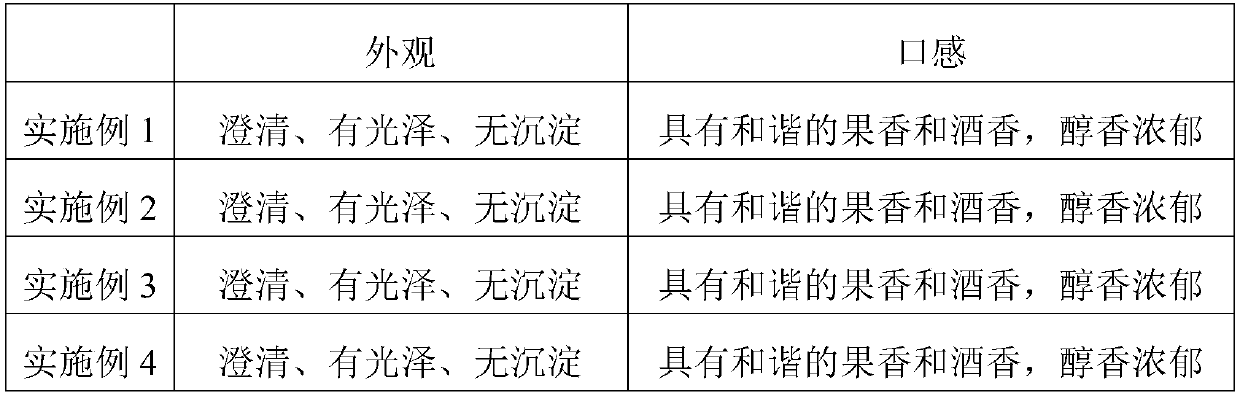

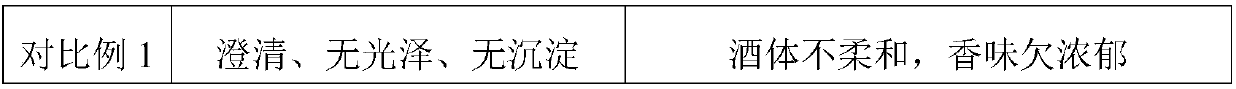

Examples

Embodiment 1

[0024] A preparation method of sugarcane and grape compound fruit wine, comprising the following steps:

[0025] S1: Select fresh sugarcane, wash and peel it, put it into the press to squeeze the raw sugarcane juice, then filter the raw sugarcane juice with a 300-mesh sieve, remove the filter residue, heat the sugarcane filtrate to 95-105°C, and boil After 10 minutes, filter with a 40nm ceramic membrane, cool the obtained sugarcane juice filtrate to 30-35°C, add proteolytic enzyme 60mg / L, cellulase, stir evenly, control the temperature at 28-32°C, and place it for 15 hours to obtain enzymolysis sugarcane juice for later use;

[0026] S2: Wash the grapes, mash them, remove seeds, and add rock sugar, 52° liquor, food-grade sulfur dioxide solution and proteolytic enzyme 50mg / L in the ratio of rock sugar: 52° liquor: food grade sulfur dioxide solution = 8:0.8:0.6 , Cellulase 30mg / L mixed, put into a sealed tank for enzymolysis, control the temperature at 28-32°C, leave it for 48h...

Embodiment 2

[0030] A preparation method of sugarcane and grape compound fruit wine, comprising the following steps:

[0031] S1: Select fresh sugarcane, wash and peel it, put it into a press to squeeze the raw sugarcane juice, then filter the raw sugarcane juice with a 240-mesh sieve, remove the filter residue, heat the sugarcane filtrate to 95-105°C, and boil 9min, then filter with a 20nm ceramic membrane, cool the obtained sugarcane juice filtrate to 30-35°C, add proteolytic enzyme 70mg / L, cellulase and stir evenly, control the temperature at 28-32°C, place it for 18h, and obtain enzymolysis sugarcane juice for later use;

[0032] S2: Wash the grapes, mash them, remove seeds, and add rock sugar, 52° liquor, food-grade sulfur dioxide solution and proteolytic enzyme 60mg / L in the ratio of rock sugar: 52° white wine: food-grade sulfur dioxide solution = 5:0.5:0.2 , cellulase 40mg / L mixed, put into a sealed tank for enzymolysis, control the temperature at 28-32°C, let stand for 24 hours, f...

Embodiment 3

[0036] A preparation method of sugarcane and grape compound fruit wine, comprising the following steps:

[0037] S1: Select fresh sugarcane, wash and peel it, put it into the press to squeeze the raw sugarcane juice, then filter the raw sugarcane juice with a 280-mesh sieve, remove the filter residue, heat the sugarcane filtrate to 95-105°C, and boil 10min, then filter with a 30nm ceramic membrane, cool the obtained sugarcane juice filtrate to 30-35°C, add proteolytic enzyme 50mg / L, cellulase and stir evenly, control the temperature at 28-32°C, and place it for 12h to obtain enzymolysis sugarcane juice for later use;

[0038] S2: Wash the grapes, mash them, remove seeds, and add rock sugar, 52° liquor, food-grade sulfur dioxide solution and proteolytic enzyme 70mg / L in the ratio of rock sugar: 52° white wine: food grade sulfur dioxide solution = 6:0.6:0.3 , cellulase 50mg / L mixed, put into a sealed tank for enzymolysis, control the temperature at 28-32°C, place for 32h, filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com