Method for prolonging service life of magnesium electrolytic bath

A magnesium electrolytic cell and electrolytic cell technology, applied in the field of electrolytic magnesium production, can solve problems affecting the life of the electrolytic cell, etc., and achieve the effects of large promotion and application prospects, reduced production costs, and reduced overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

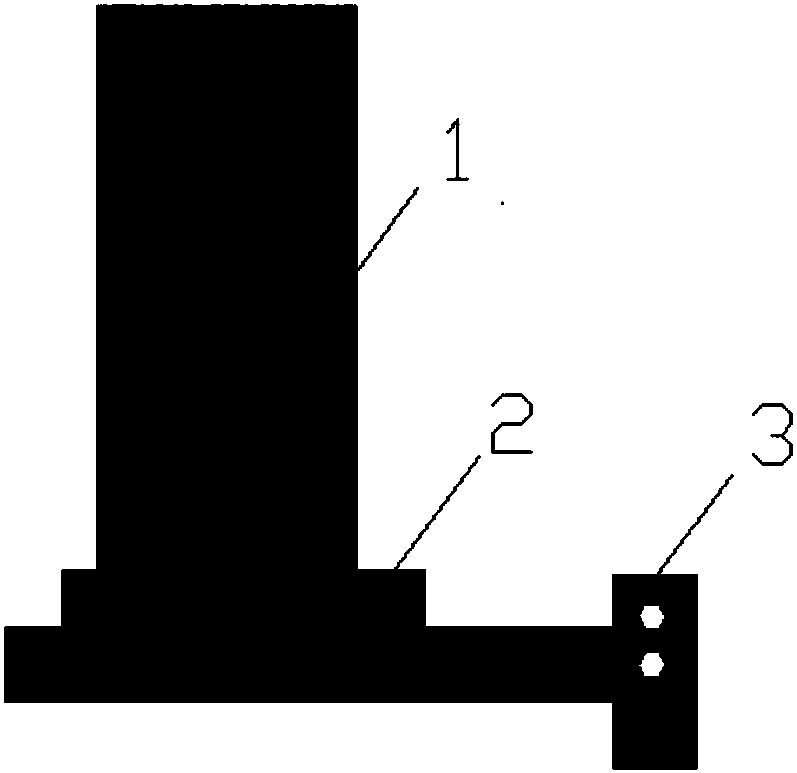

Image

Examples

Embodiment 1

[0023] Use sponge titanium production process to steam MgCl 2 As a raw material, the MgO content is 0.5-1.25%, and the MgO content in the electrolyte is 0.05-0.08% after purification in the electrolyte purification device for 0.5h under the condition of 750°C and an electrolysis voltage of 3.0V. Then add the above-mentioned purified electrolyte that meets the requirements into the magnesium electrolysis cell of the lower-insertion graphite anode and the side-insertion carbon steel cathode, and monitor the electrode current to control the electrode current distribution within 10%. After 3 years of operation, electrolysis The tank voltage is increased by 0.01V, and the graphite electrode is reduced by 1.1%, and stable operation can still be continued.

Embodiment 2

[0025] Using carnallite as raw material, the content of MgO is 1.5 to 5%. Under the condition of 750°C and an electrolysis voltage of 3.1V, the MgO content in the electrolyte is 0.07-0.09% after purification in the electrolyte purification device for 1 hour. Then, the purified electrolyte that meets the requirements is added to the side-insertion graphite anode and the lower-insertion carbon steel cathode magnesium electrolysis cell, and the electrode current is monitored to control the electrode current distribution within 8%. After 3 years of operation, electrolysis The tank voltage is increased by 0.05V, and the graphite electrode is reduced by 2.3%, and stable operation can still be continued.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com