Laser annealing apparatus and laser annealing method

A laser annealing and laser technology, applied in chemical instruments and methods, crystal growth, electrical components, etc., can solve problems such as poor process adaptability, inability to take measures to eliminate pattern effects, and low degree of control freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

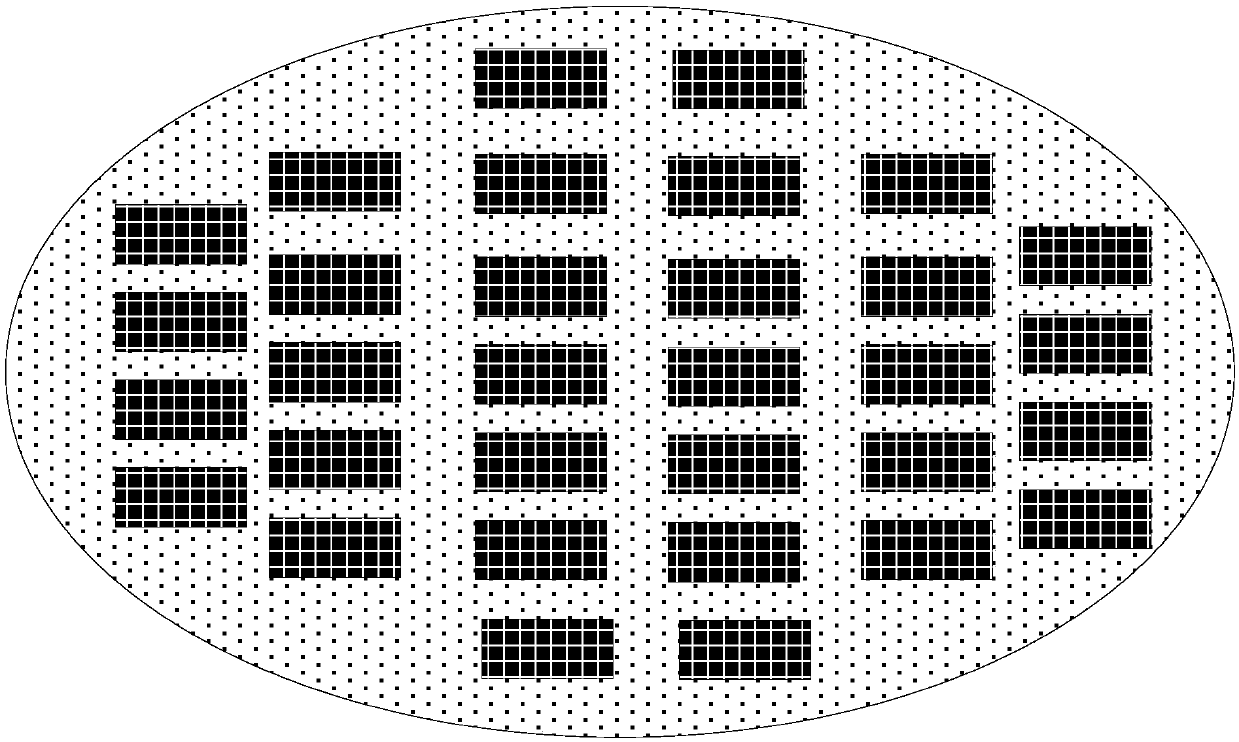

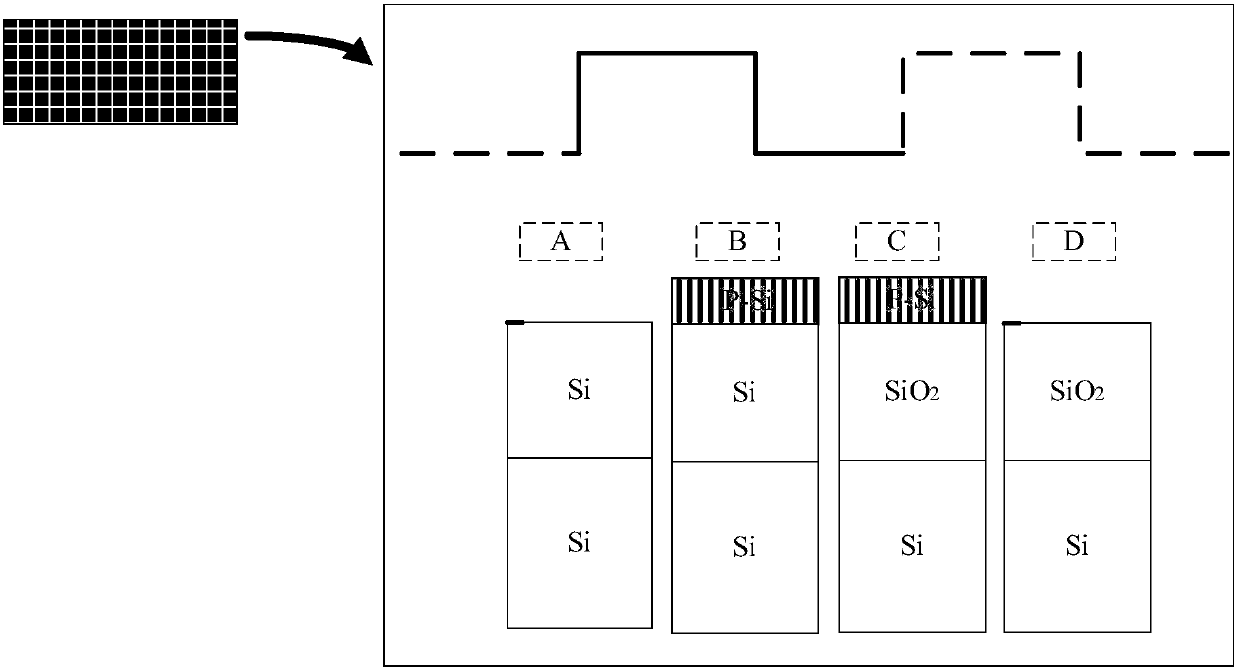

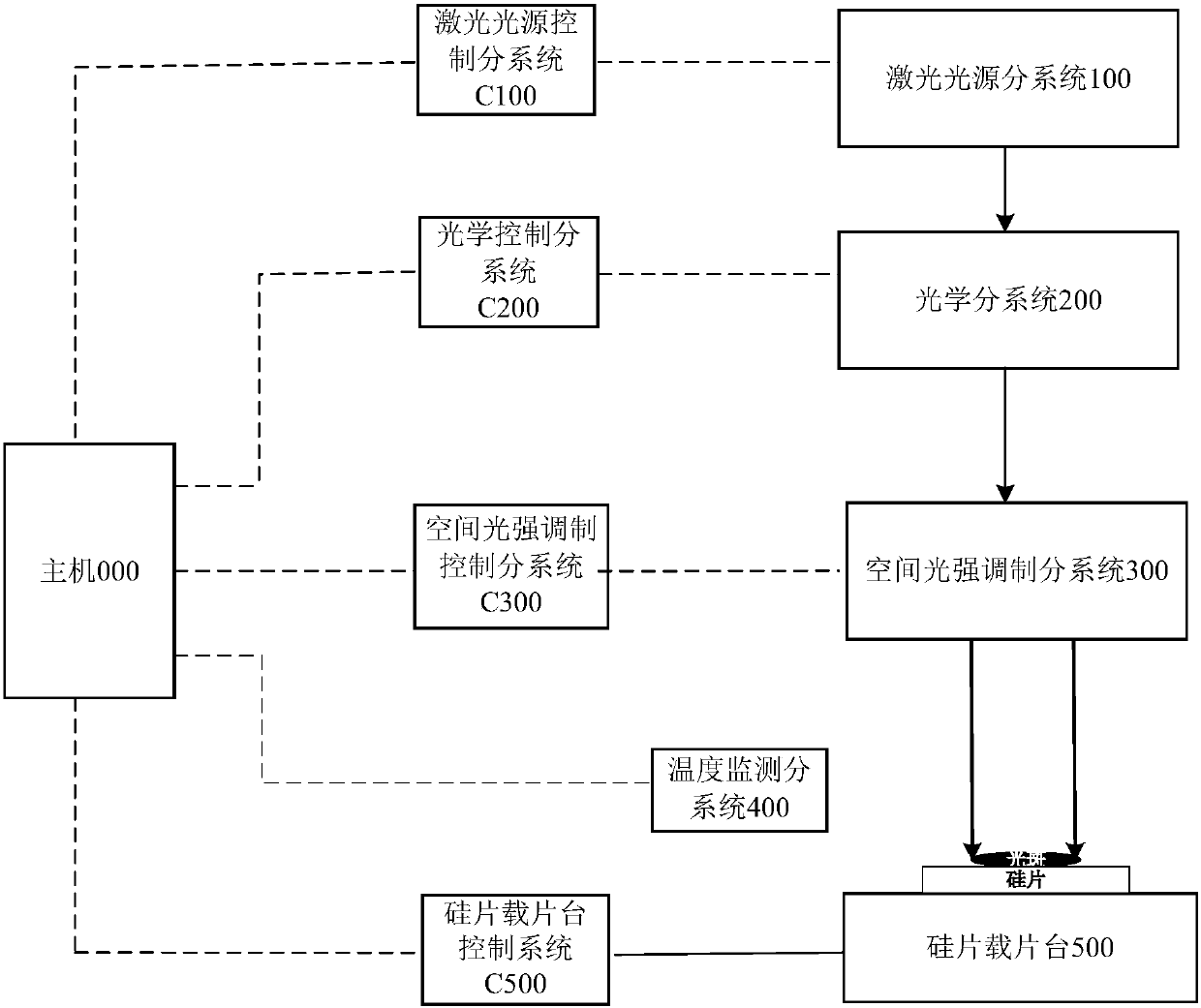

[0063] The following will combine Figure 1 to Figure 6 The annealing device for improving annealing uniformity based on reflectivity distribution provided by the present invention is described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can, within the scope of not changing the spirit and content of the present invention, Revise and polish it.

[0064] The present invention provides an annealing device for improving annealing uniformity based on reflectivity distribution, including a host 000, a laser light source subsystem 100, an optical subsystem 200, a spatial light intensity modulation subsystem 300, and a temperature monitoring subsystem 400, wherein:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com