Double-effect free-piston Stirling thermal driving refrigerator/heat pump system

A heat pump system and refrigerator technology, which is applied in the field of double-effect free-piston Stirling heat-driven refrigerator/heat pump system, can solve the problems of restricting the development and application of refrigerators, low power density, and reduced reliability, etc. Energy saving and emission reduction effect, high power density, and mechanical vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

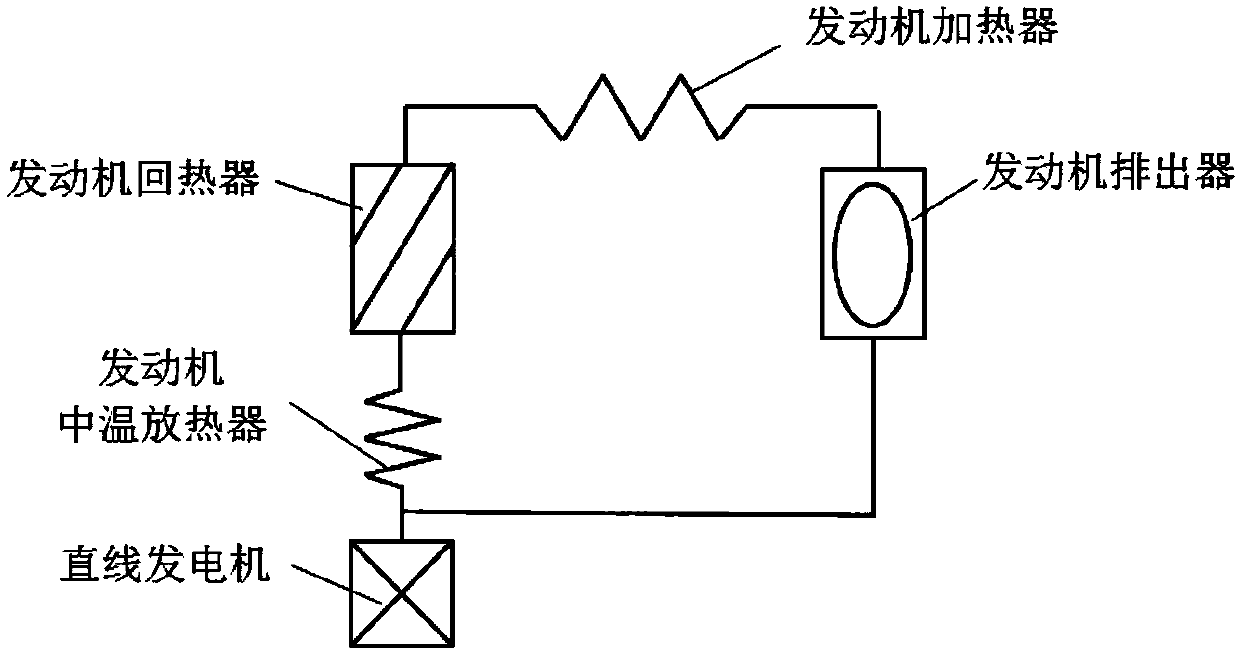

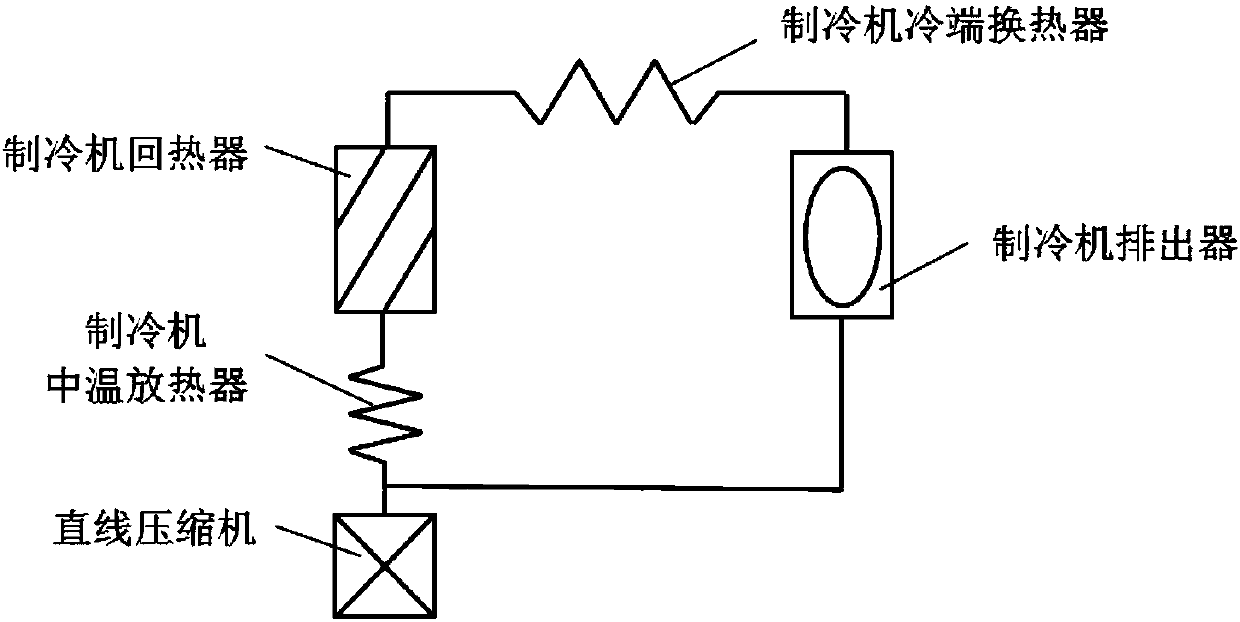

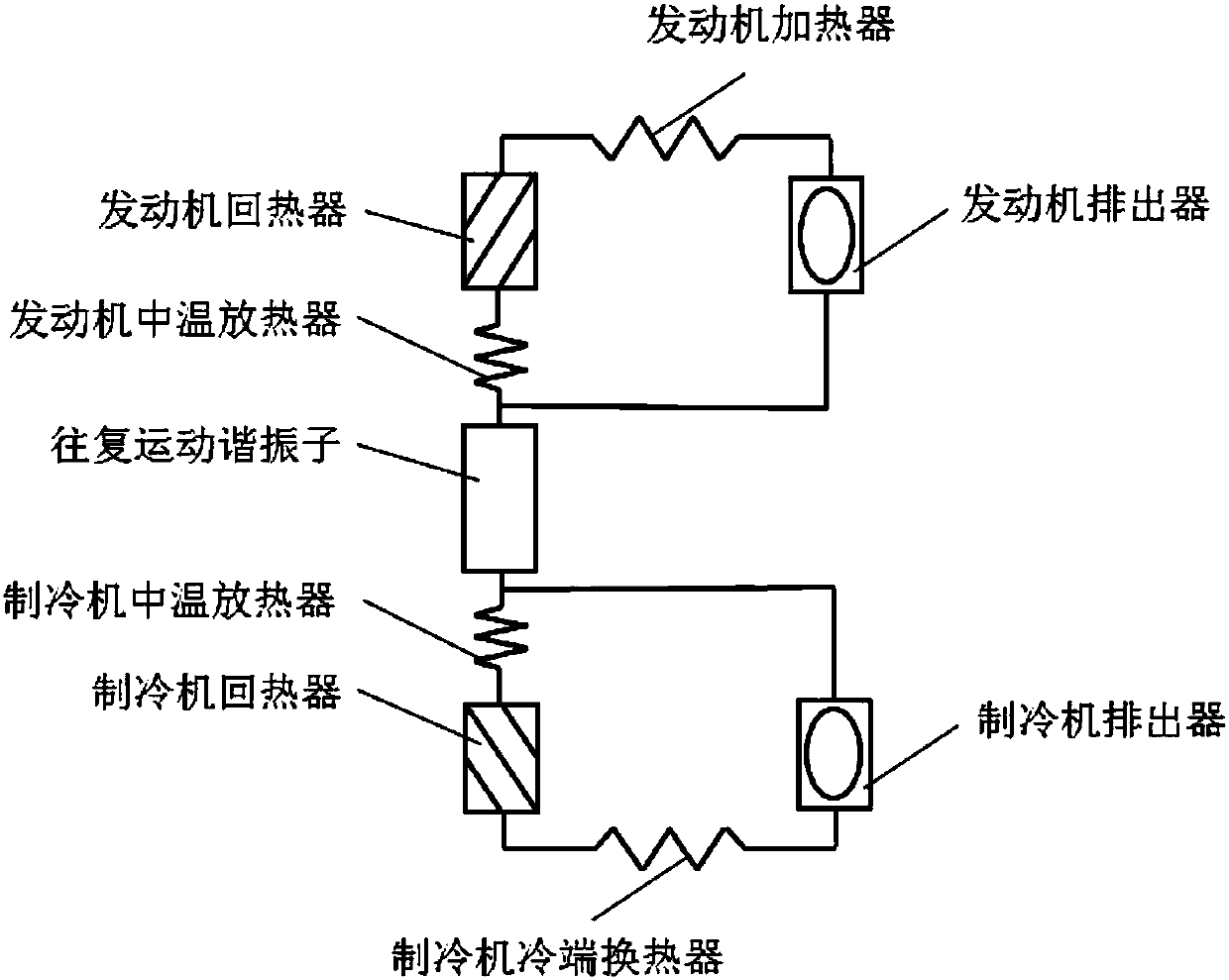

[0039] Such as Figure 5 As shown, a double-effect free-piston Stirling heat-driven refrigerator / heat pump system according to Embodiment 1 of the present invention includes: a double-effect free-piston Stirling refrigerator circuit and a reciprocating resonant oscillator 1 . The circuit of the double-effect free-piston Stirling refrigerator includes: engine mid-temperature radiator 2, engine regenerator 3, engine heater 4, engine heat buffer pipe 5, refrigerator mid-temperature radiator 6 connected end to end in sequence , refrigerating machine regenerator 7, refrigerating machine cold end heat exchanger 8 and refrigerating machine ejector 9; the reciprocating resonator 1 is connected with the engine mid-temperature radiator 2 and refrigerating machine ejector 9 for regulating the system resonance frequency and sound field phase.

[0040] The heat absorbed from the engine heater 4 comes from low-grade heating heat sources, such as industrial waste heat, automobile exhaust wa...

Embodiment 2

[0046] In order to better realize the purpose of application and promotion, the whole machine can adopt a coaxial structure, which will make the structure more compact and improve the reliability. Such as Figure 7 As shown, the double-effect free-piston Stirling heat-driven refrigerator / heat pump system in Embodiment 2 has the same components as the system in Embodiment 1, and the system includes a double-effect free-piston Stirling refrigerator circuit and a reciprocating motion Harmonic oscillator 1. The difference between Embodiment 2 and Embodiment 1 is that the circuit of the double-effect free-piston Stirling refrigerator is arranged in a coaxial structure, with the refrigerator discharger 9 as the central axis, and arranged in sequence from bottom to top along the axial direction There are: engine mid-temperature radiator 2, engine regenerator 3, engine heater 4, engine heat buffer pipe 5, refrigerator mid-temperature radiator 6, refrigerator regenerator 7 and refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com