Graphene Bulletproof Helmet

A graphene bulletproof head, graphene technology, applied in protective equipment, synthetic resin layered products, offensive equipment and other directions, can solve the problems of graphene bulletproof helmets that have not been reported, and achieve the effect of reducing product quality and improving ballistic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

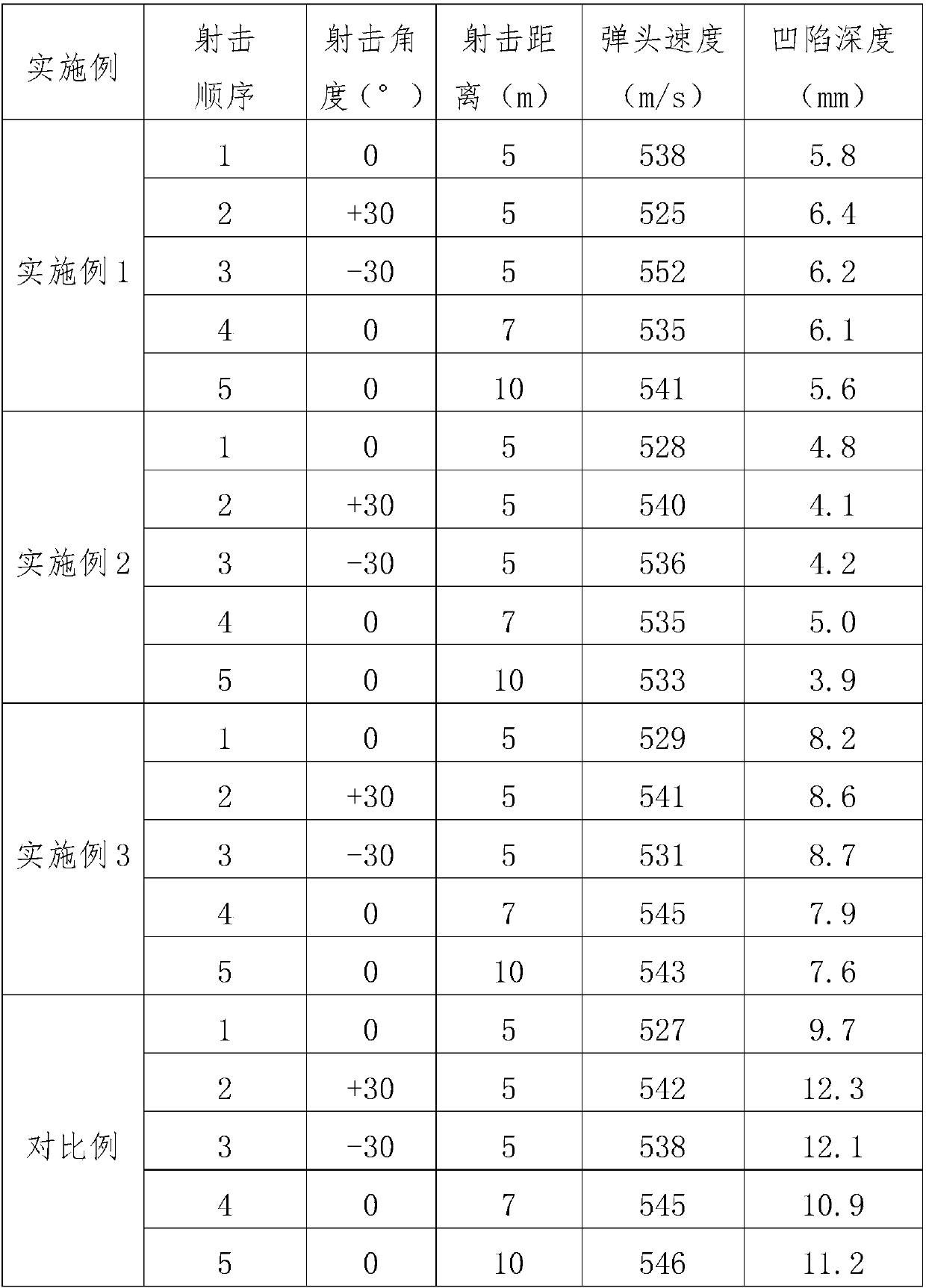

Embodiment 1

[0012] Preferred embodiment 1 of the present invention provides a graphene bulletproof helmet, which is a three-layer sandwich structure bonded together by an adhesive. The layer is a sponge structure composite reinforced by silicon carbide, graphene and aluminum. The preparation method of the sponge composite is: mixing graphene and silicon dioxide-coated aluminum powder with alcohol solution, wherein graphene accounts for the mixed solution The percentage by weight of silicon dioxide is 7%, and the percentage by weight of silicon dioxide-coated aluminum powder in the mixed solution is 4%; then get silicon carbide powder equal to the weight of graphene, and add it to the above mixed solution, and ultrasonically mix and stir for 1.5 ~ 2 hours to get a mixed suspension; immerse the open-cell polyurethane sponge into the mixed suspension, and apply pressure to discharge the gas in the open-cell polyurethane sponge, and continue ultrasonic oscillation for 6-8 hours; then put the c...

Embodiment 2

[0016] Preferred embodiment 2 of the present invention provides a graphene bulletproof helmet, which is a three-layer sandwich structure bonded together by an adhesive. The layer is a sponge structure composite reinforced by silicon carbide, graphene and aluminum. The preparation method of the sponge composite is: mixing graphene and silicon dioxide-coated aluminum powder with alcohol solution, wherein graphene accounts for the mixed solution The percentage by weight of silicon dioxide is 8%, and the percentage by weight of silicon dioxide-coated aluminum powder in the mixed solution is 5%; then take silicon carbide powder equal to the weight of graphene, and add it to the above mixed solution, and ultrasonically mix and stir for 1.5 ~ 2 hours to get a mixed suspension; immerse the open-cell polyurethane sponge into the mixed suspension, and apply pressure to discharge the gas in the open-cell polyurethane sponge, and continue ultrasonic oscillation for 6-8 hours; then put the ...

Embodiment 3

[0020] Preferred embodiment 3 of the present invention provides a graphene bulletproof helmet, which is a three-layer sandwich structure bonded together by an adhesive. The layer is a silicon carbide, graphene mixed reinforced sponge structure composite, and the preparation method of the sponge composite is: graphene is mixed with alcohol solution, wherein graphene accounts for 8% by weight of the mixed solution, and then taken with Add silicon carbide powder equal to the weight of graphene to the above mixed solution, and ultrasonically mix and stir for 1.5 to 2 hours to obtain a mixed suspension; immerse the open-cell polyurethane sponge in the mixed suspension, and apply pressure to discharge the open The gas in the porous polyurethane sponge continues to be ultrasonically oscillated for 6 to 8 hours; then the coated polyurethane sponge is dried at room temperature for 2 hours to obtain a sponge composite, which is then placed in a heating furnace and heated under a nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com