Optimum design method for fan/gas compressor end wall profile and optimization platform

An optimized design, compressor technology, applied in the direction of calculation, genetic model, special data processing application, etc., can solve the problems of complex counter-pressure flow environment in the through-flow part, sharp inherent contradictions in stall margin, etc., to improve the overall aerodynamic performance, Streamlined optimization steps and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] An optimal design method for the end wall profile of a fan / compressor, establishing an optimal design method for the end wall profile of a fan / compressor based on a quasi-three-dimensional system, and integrating it into a corresponding optimal design platform. The quasi-three-dimensional optimal design method includes The following steps:

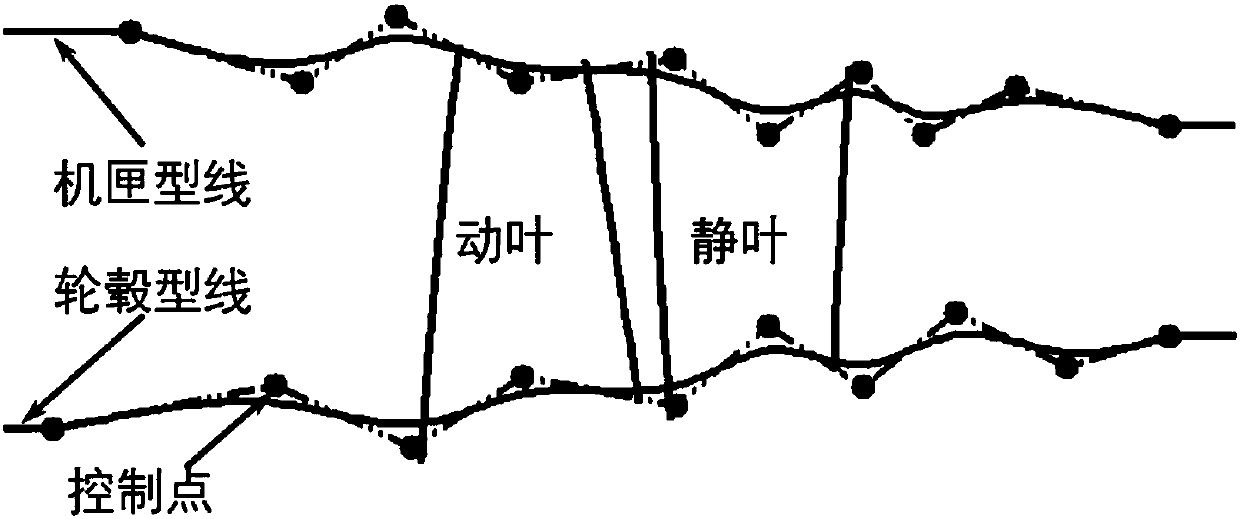

[0065] Step 1: First, parameterize the original design of the axial fan hub and casing;

[0066] Step 2: extract the data information of the control point parameters, and use the cubic spline function for correlation; the correlation is to use the cubic spline function to express the original design of the axial fan hub and the shape of the casing, so as to optimize the design in the next step;

[0067] Step 3: Execute the shell script program;

[0068] Step 4: Generate new control parameters and end wall profile scheme samples;

[0069] Step 5: Use the new control parameters and end wall profile scheme samples as quasi-three-dime...

Embodiment 2

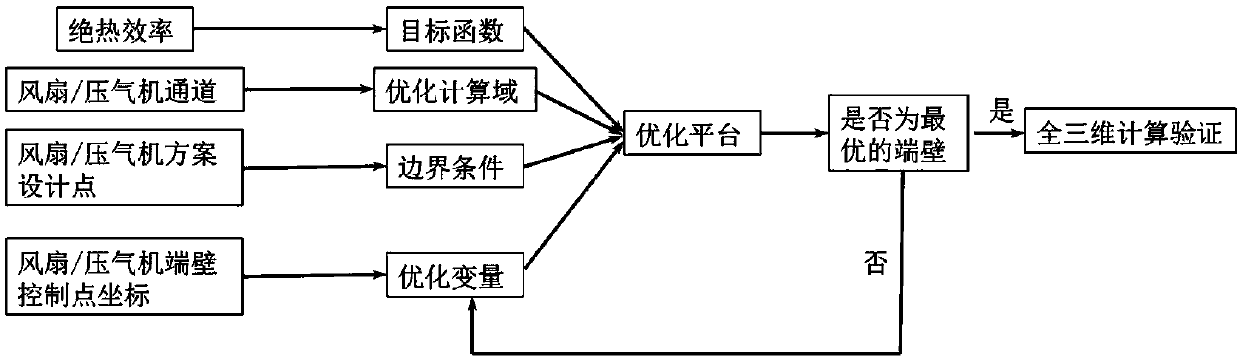

[0075] The optimization platform of the optimal design method of a fan / compressor end wall profile described in Embodiment 1, the optimal design platform of its end wall comprises the following steps:

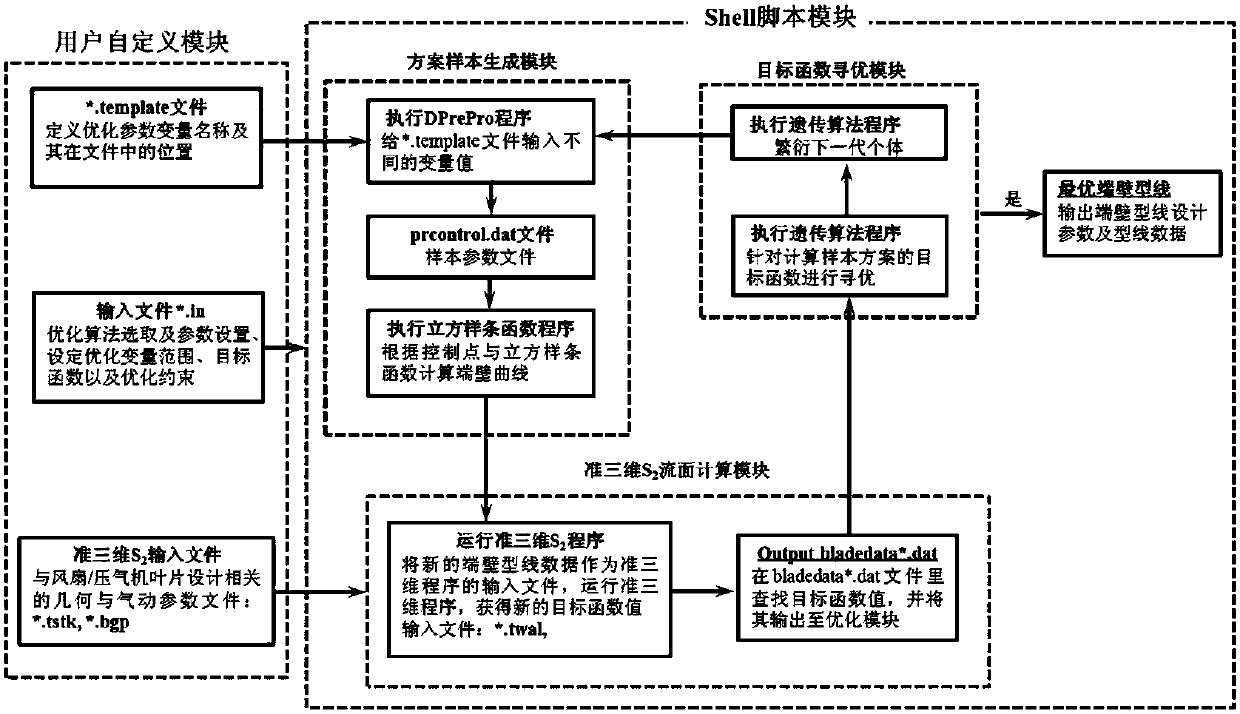

[0076] Step 1: the user defines the optimization parameter variable name and its position in the file in the template file;

[0077] Step 2: Selection of optimization algorithm and parameter setting, setting of optimization variable range, objective function and optimization constraints;

[0078] Step 3: Carry out Step 1 and execute the DPrePro program, and input different variable values to the template file;

[0079] Step 4: Input the Prcontrol.dat file, the sample parameter file;

[0080] Step 5: Execute the cubic spline function program, and calculate the end wall curve according to the control points and the cubic spline function;

[0081] Step 6: Quasi-3D S 2 Input files, geometric and aerodynamic parameter files related to fan / compressor blade design: *.tstk, *.bgp;...

Embodiment 3

[0087] The optimal design method of a kind of fan / compressor end wall molding line described in embodiment 1 first separately optimizes the design of the wheel hub molding line, and then optimizes the design of the casing molding line on this basis, and the specific steps are as follows:

[0088] Step S101: Parametric analysis and processing of the profile data of the prototype fan / compressor hub. That is, based on the original design data of the fan / compressor hub, the corresponding control point data information is extracted, and the geometric characteristics of the hub profile are expressed through the information of the control points and the cubic spline function;

[0089] Step S102: establishing a mathematical model for the optimal design of the hub shape;

[0090] The adiabatic efficiency of the fan / compressor stage is used as the objective function, and the coordinate information of the control points is used as the optimization variable to establish a mathematical mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com