Make-up removal wet tissue and preparation method thereof

A technology of wet wipes and makeup remover, which is applied in the field of makeup remover products, can solve the problems of not being suitable for sensitive skin, dry skin, and unable to moisturize the skin, etc., and achieve the effect of excellent cleaning and antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

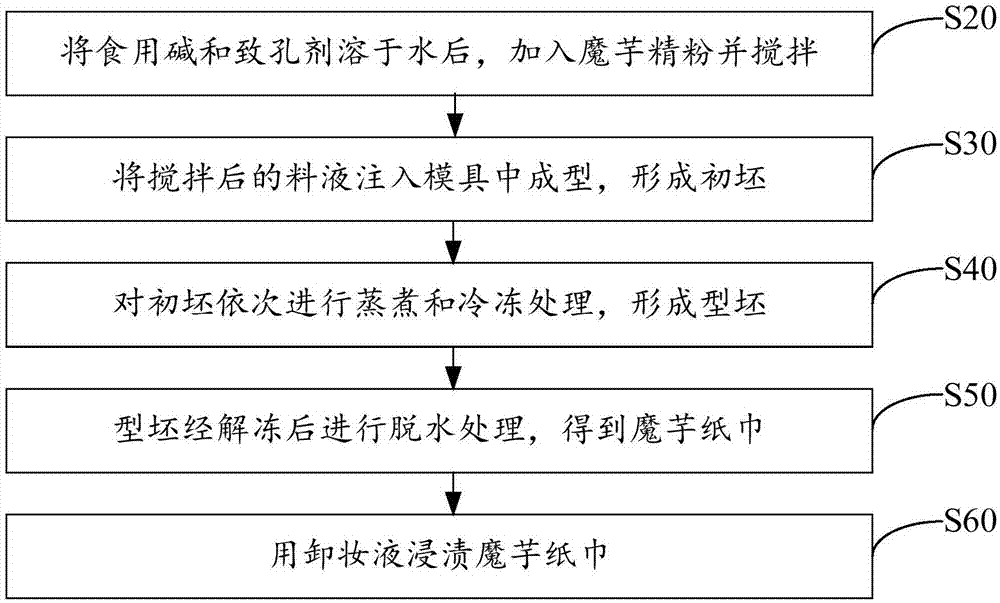

[0043] The present invention also proposes a preparation method of makeup remover wet tissue, figure 1 For an embodiment of the preparation method of the makeup remover wet tissue provided by the present invention, please refer to figure 1 , the preparation method of described cleansing wet tissue comprises the steps:

[0044] Step S20, after dissolving edible alkali and porogen in water, add konjac fine powder and stir;

[0045] Weigh the edible alkali, porogen and konjac fine powder respectively, completely dissolve the edible alkali and porogen in water, then add the konjac fine powder and stir until the mixture is in a semi-gel state.

[0046]Step S30, injecting the stirred material liquid into the mold to form a preform;

[0047] The material liquid stirred to a semi-gel state is injected into a molding mold through a filling machine, and the size of the mold is usually 170mm*170mm. After the konjac powder is dissolved in water, it will gradually solidify and form a ge...

specific Embodiment 1

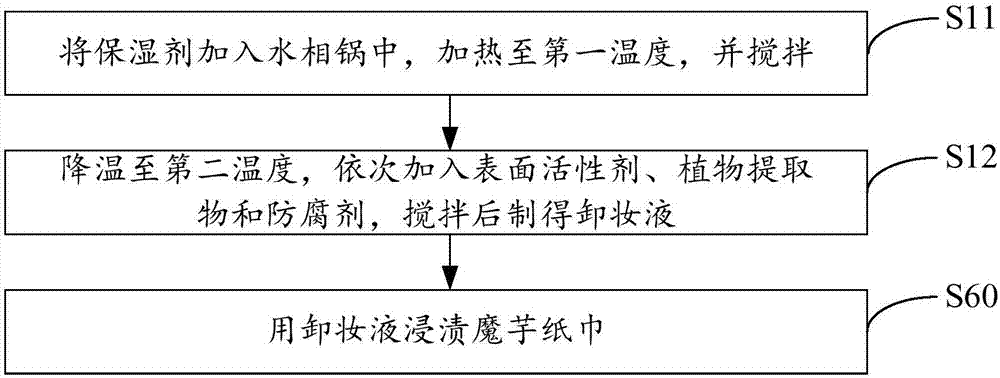

[0064] (1) Preparation of makeup remover: Weigh 1g of allantoin, 8g of purslane extract, 12g of caprylic acid / capric triglyceride, 10g of phenoxyethanol and 69g of deionized water, place allantoin and deionized water in Heat the water phase pot to 85°C, stir evenly, then cool down to 45°C, then add caprylic / capric triglyceride, purslane extract and phenoxyethanol in sequence, and stir well to obtain a makeup remover.

[0065] (2) Weigh 3.5g edible alkali, 0.7g Tween 20, 700g konjac powder (80% glucomannan content) and 9300g purified water, first dissolve edible alkali and Tween 20 in purified water, then add Konjac fine powder was stirred for 8 minutes to obtain feed liquid.

[0066] (3) Fill the feed liquid into a mold with a size of 170mm*170mm through a filling machine, and obtain a formed blank after filling is completed.

[0067] (4) Gradient cooking is carried out on the preform. The cooking temperature is 100-105°C. After cooking for 1.5 hours, it is cooled to room tem...

specific Embodiment 2

[0069] (1) The makeup remover of specific embodiment 2 is prepared with specific embodiment 1.

[0070] (2) Weigh 14g edible alkali, 1.75g Tween 20, 700g konjac fine powder (glucomannan content is 90%) and 9300g purified water, first dissolve edible alkali and Tween 20 in purified water, then add konjac The refined powder was stirred for 6 minutes to obtain a feed liquid.

[0071] (3) Fill the material liquid into a mold with a size of 170mm*170mm through a filling machine, and obtain a formed blank after the filling is completed.

[0072] (4) Gradient cooking is carried out on the preform. The cooking temperature is 100-105°C. After cooking for 1.5 hours, it is cooled to room temperature, and then placed in a cold storage for freezing treatment. The freezing temperature is -18°C, and the parison is obtained after freezing for 2 days.

[0073] (5) After the parison is thawed, rinsed and trimmed successively, the konjac paper towel (mass is about 10g) is obtained after dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com