Multifunctional loaded catalyst, preparation method thereof, and application of catalyst to combined removal of CO in flue gas

A supported catalyst, multifunctional technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of improving oxygen utilization efficiency, inhibiting toxic effects, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Correspondingly, the present invention provides a kind of preparation method of multifunctional supported catalyst, comprising the following steps:

[0047] A supported metal-based catalyst is provided, the supported metal-based catalyst includes a carrier and a metal-based active component supported on the carrier;

[0048] The supported metal catalyst is mixed with the base component solution and dried to obtain a multifunctional supported catalyst.

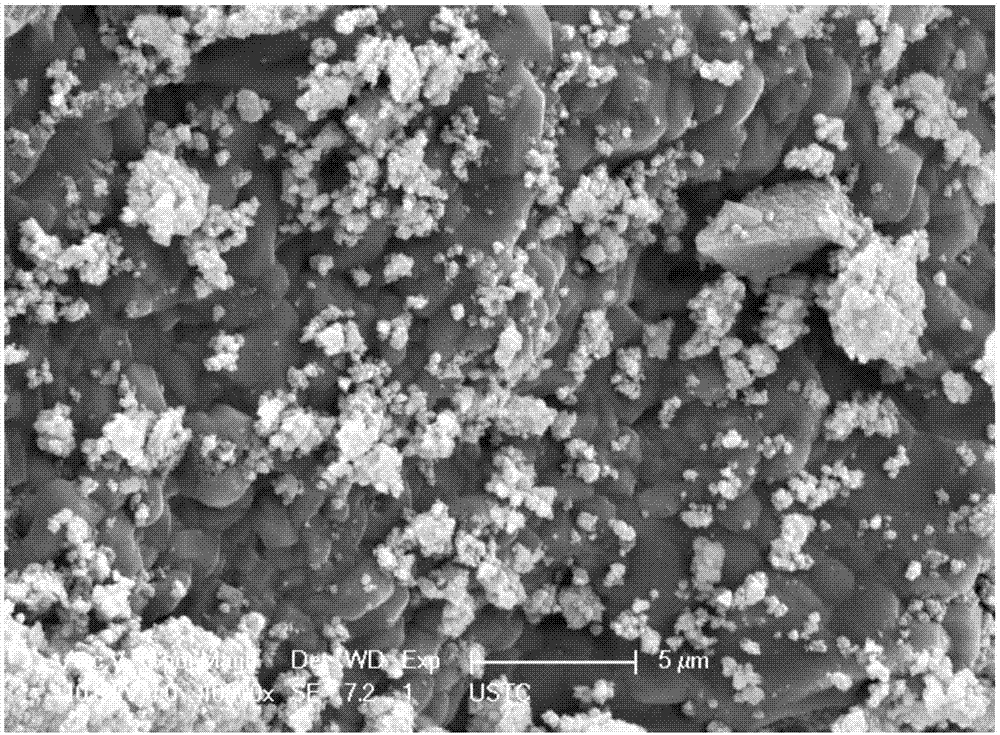

[0049] The embodiments of the present invention firstly provide a supported metal catalyst, which includes a carrier and a metal active component supported on the carrier. Wherein, the carrier is preferably selected from activated carbon, silica gel or molecular sieves. The metal active component can be selected from one or more of noble metals, transition metal oxides and transition metal composite oxides; the metal element in the metal active component is preferably one or more of copper and manganese two kinds. In ...

Embodiment 1

[0066] 1. Catalyst precursor preparation:

[0067] The multifunctional catalyst uses wood activated carbon as a carrier, KOH as a base component and copper-manganese composite oxide as an active component.

[0068] According to the molar ratio of base component and copper-manganese salt is 1:2:2, weigh 2.8g KOH, 20.0g C 4 h 6 CuO 4 ·H 2 O and 24.5g C 4 h 6 MnO 4 4H 2 O. Will C 4 h 6 CuO 4 ·H 2 O and C 4 h 6 MnO 4 4H 2 O was dissolved in 400 mL of deionized water, and the constant temperature water bath was continuously stirred for 2 hours to prepare a mixed salt solution with a concentration of 0.5 mol / L. Weigh 150.7g wood activated carbon carrier, add the mixed salt solution, and continue to stir for 12h under 2.0MPa in the autoclave, so that the active component precursor is evenly loaded on the carrier; then the mixed system is moved into a rotary vacuum evaporator , dried at 85° C. for 12 hours, and then calcined in a muffle furnace at 350° C. for 6 hours ...

Embodiment 2

[0076] 1. Catalyst precursor preparation:

[0077] The multifunctional catalyst uses coconut shell activated carbon as a carrier, NaOH as a base component, and copper-manganese composite oxide as an active component.

[0078] Similar to Example 1, the molar ratio of base component and copper-manganese salt is 1:2:2, respectively weigh 2.0g NaOH, 20.0g C 4 h 6 CuO 4 ·H 2 O and 24.5g C 4 h 6 MnO 4 4H 2 O. Will C 4 h 6 CuO 4 ·H 2 O and C 4 h 6 MnO 4 4H 2 O was dissolved in 400 mL of deionized water, and the constant temperature water bath was continuously stirred for 2 hours to prepare a mixed salt solution with a concentration of 0.5 mol / L. The coconut shell activated carbon carrier of 146.2g was added to the mixed salt solution, and was continuously stirred for 8h under the high-pressure reactor 2.0MPa, so that the active component precursor was evenly loaded on the carrier; then the mixed system was moved into a rotary vacuum evaporator, and was heated at 105 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

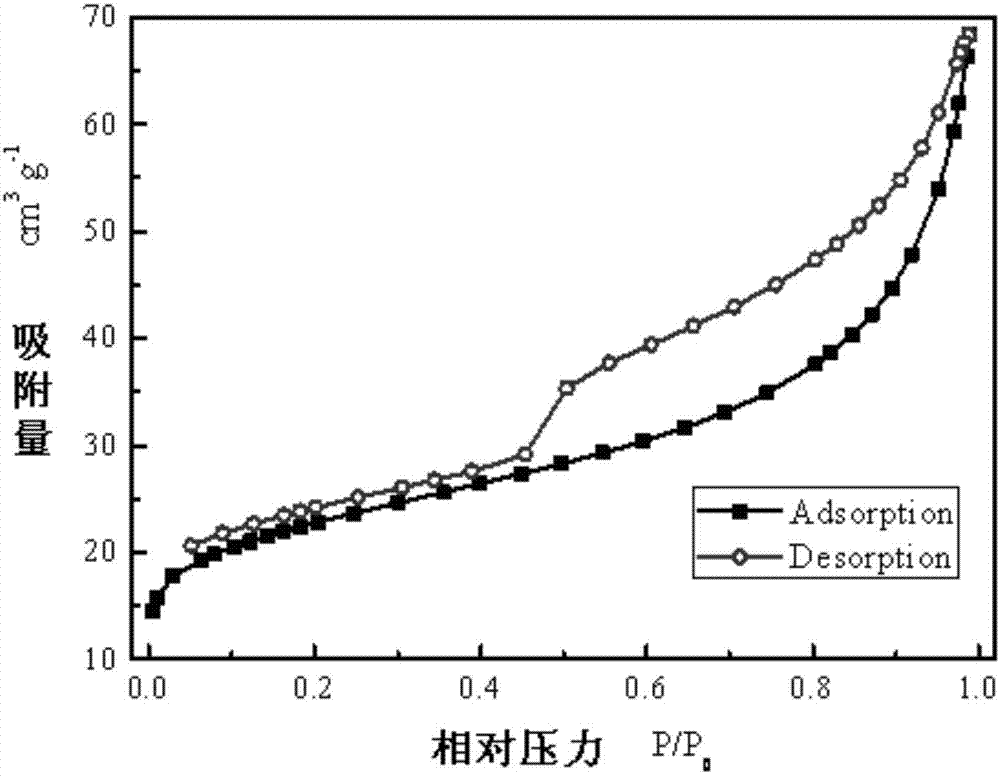

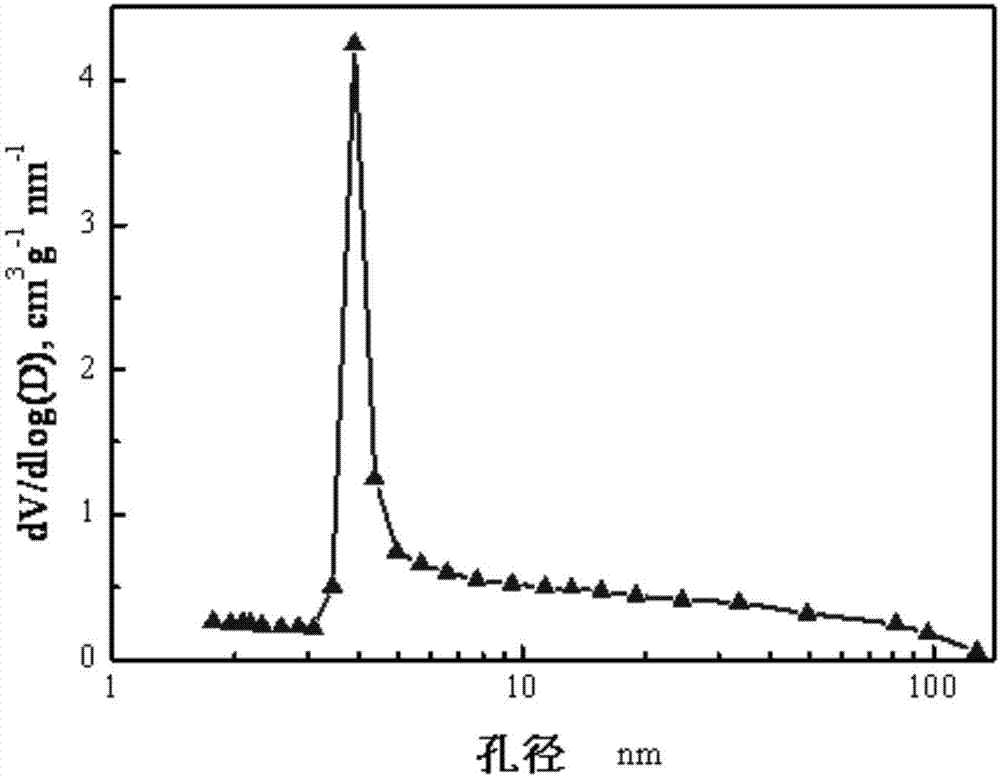

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com