Gas liquid double-fluid electrostatic atomization device

An electrostatic atomization and two-fluid technology, applied in the direction of spray discharge device, etc., can solve the problems of low nozzle spray efficiency, easy breakdown of electrodes, damage of device components, etc., achieve good adaptability, and improve the charge-to-mass ratio of droplets , The effect of preventing charge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the specific embodiments of the accompanying drawings, but the protection scope of the present invention is not limited thereto.

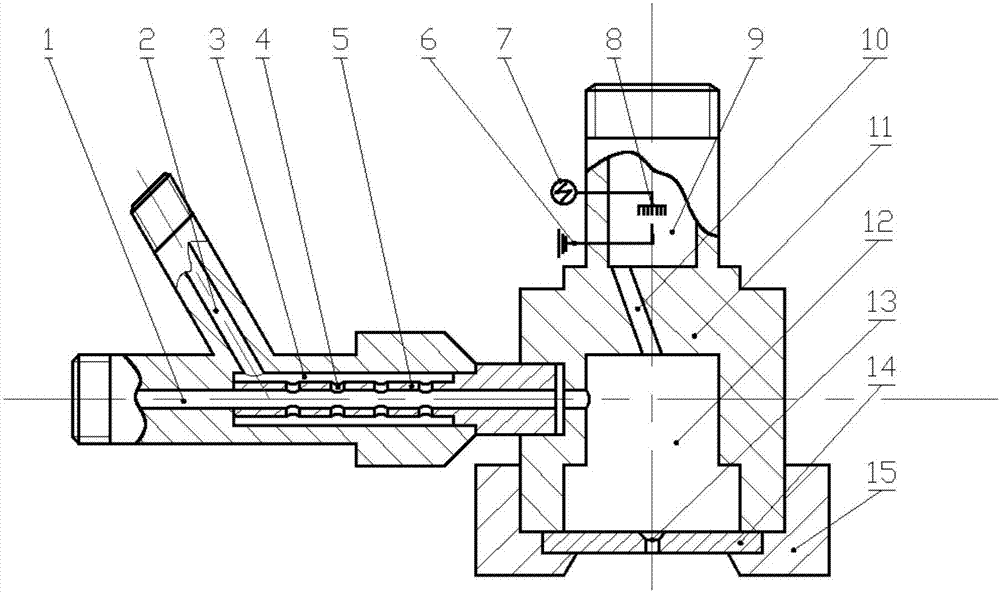

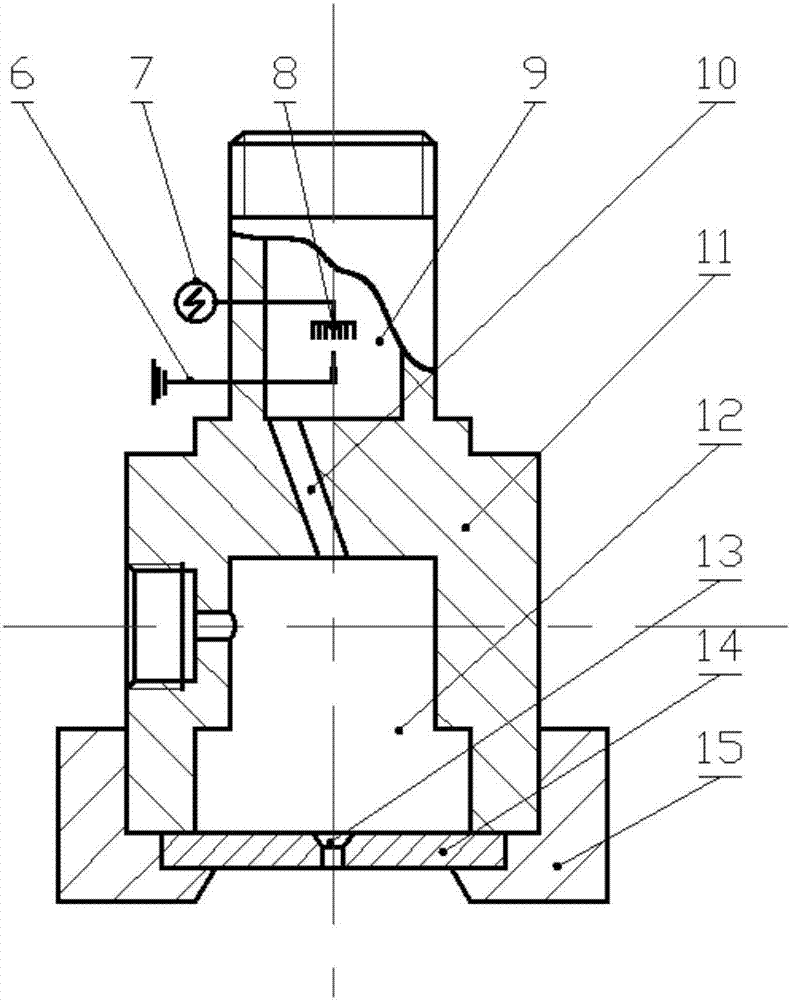

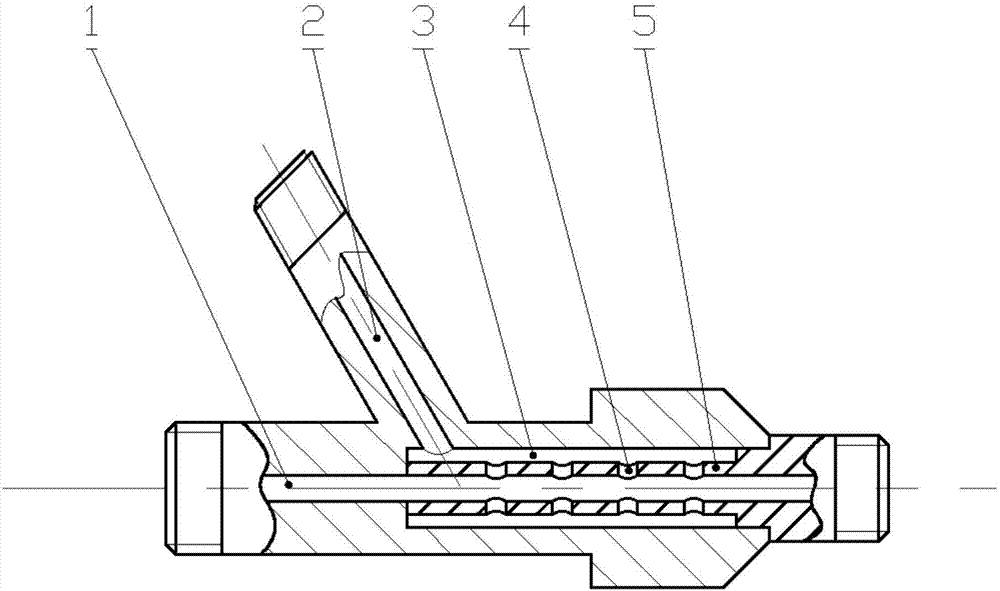

[0034] Such as figure 1 As shown, a gas-liquid two-fluid electrostatic atomization device includes an air discharge chamber 9, a brush electrode 8, a needle-shaped ground electrode 6, a negative high voltage generator 7, a charged air channel 10, a gas-liquid mixing chamber 12, a liquid Channel 1, air inlet channel 2, air channel 3, isolation tube 5, vent hole 4, casing 11, pressing body 14 and gland 15; the air discharge chamber 9 is a hollow cylinder with brush-shaped electrodes 8 and The needle-shaped ground electrode 6 and the air discharge chamber 9 communicate with the gas-liquid mixing chamber 12 through the charged air channel 10; the lower end of the shell 11 seals the gas-liquid mixing chamber 12 through a circular pressing body 14, and a nozzle 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com