Stabilizing material as well as preparation method and application thereof

A technology of stabilizing materials and grading crushed stone, applied in the field of materials, can solve problems such as unhelpful sustainable development of the environment, increase consumption of natural raw materials, and affect the ecological environment, so as to save road construction materials, improve road quality, and protect the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Prepare materials

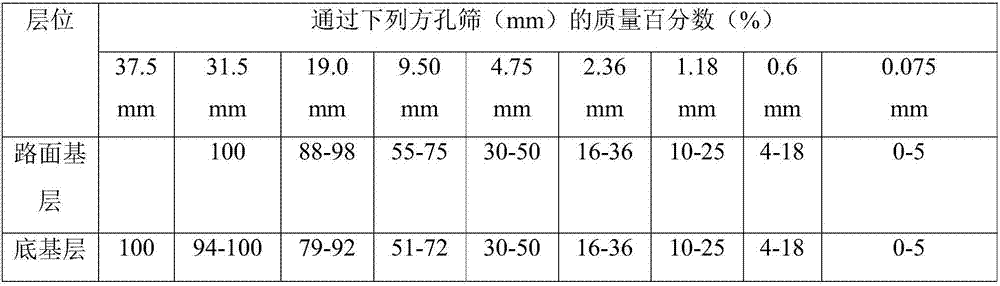

[0029] 80 parts by weight of graded gravel, 6 parts by weight of calcium silicate slag (calculated on a dry basis), 4 parts by weight of fly ash, 2 parts by weight of cement, and 8 parts by weight of water, wherein the moisture content of calcium silicate slag is lower than 30% , the particle size distribution of the graded crushed stone is 0.075-31.5mm and the mass fraction of the crushed stone of each particle size within the particle size range is: the weight of the crushed stone with a particle size less than or equal to 0.075mm accounts for the total weight of the graded crushed stone The weight of crushed stones with a particle size of 0.6mm or less accounted for 15% of the total weight of the graded crushed stones, and the weight of crushed stones with a particle size of 1.18mm or less accounted for 15% of the total weight of the graded crushed stones 20%, the weight of crushed stones with a particle size less than or equal to 2.36mm accoun...

Embodiment 2

[0048] 1. Prepare materials

[0049] 76 parts by weight of graded gravel, 9 parts by weight of calcium silicate slag (calculated on a dry basis), 6 parts by weight of fly ash, 1 part by weight of cement, and 8 parts by weight of water, wherein the moisture content of calcium silicate slag is lower than 30% , the particle size distribution of the graded crushed stone is 0.075-31.5mm and the mass fraction of the crushed stone of each particle size within the particle size range is: the weight of the crushed stone with a particle size less than or equal to 0.075mm accounts for the total weight of the graded crushed stone 4% of the weight, the weight of crushed stones with a particle size of 0.6mm or less accounts for 16% of the total weight of the graded crushed stones, and the weight of crushed stones with a particle size of 1.18mm or less accounts for 10% of the total weight of the graded crushed stones 19%, the weight of crushed stones with a particle size less than or equal t...

Embodiment 3

[0068] 1. Prepare materials

[0069] 75 parts by weight of graded gravel, 9 parts by weight of calcium silicate slag (calculated on a dry basis), 5 parts by weight of fly ash, 2 parts by weight of cement, and 9 parts by weight of water, wherein the moisture content of calcium silicate slag is lower than 30% , the particle size distribution of the graded crushed stone is 0.075-37.5mm and the mass fraction of the crushed stone of each particle size within the particle size range is: the weight of the crushed stone with a particle size less than or equal to 0.075mm accounts for the total weight of the graded crushed stone The weight of crushed stones with a particle size of 0.6mm or less accounted for 15% of the total weight of the graded crushed stones, and the weight of crushed stones with a particle size of 1.18mm or less accounted for 15% of the total weight of the graded crushed stones 23%, the weight of crushed stones with a particle size less than or equal to 2.36mm accoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com