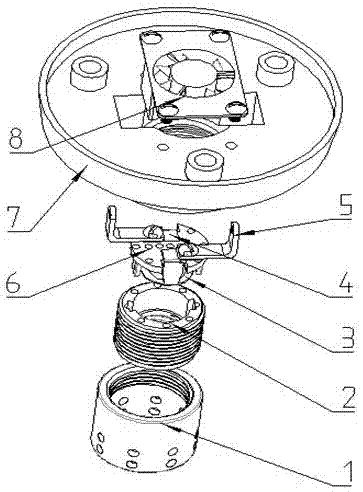

Heat dissipation LED lamp holder

A technology for LED lamp holders and heat dissipation lamp holders, applied in lighting and heating equipment, cooling/heating devices of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of low heat dissipation efficiency and achieve strong heat dissipation and good insulation performance and heat dissipation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

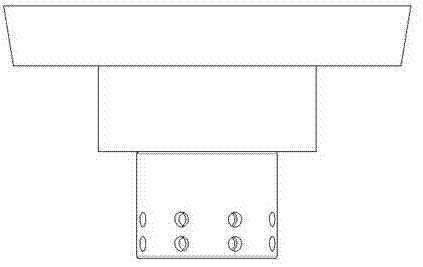

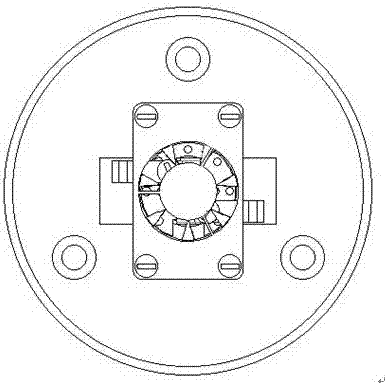

Image

Examples

Embodiment 1

[0019] Step 1, 10 parts of MgAl 2 o 4 / SSZ-13 nanomaterials, 30 parts of bentonite, 10 parts of magnesium oxide, and 20 parts of calcium carbonate were dispersed in 300 parts of absolute ethanol to form a mixed slurry, which was dried to obtain a composite sintering aid for later use;

[0020] Step 2. Add 30 parts of polymerized modified phenolic resin, 10 parts of silicon dioxide, 14 parts of boron nitride, 6 parts of hydroxymethyl cellulose, 10 parts of methyl acrylate and the composite sintering aid prepared in step 1 to the ball mill in sequence. 25 parts of the agent were wet ball milled, ball milled for 2 hours, vacuum stirred and defoamed, and ceramic slurry was prepared for subsequent use;

[0021] Step 3. Press the ceramic slurry prepared in the above steps into the mold from the bottom of the mold, place it naturally to complete the gel process, take out the ceramic green sheet and dry it at a temperature of 60°C for 2 hours, and then spread the ceramic green body i...

Embodiment 2

[0032] Step 1, 20 parts of MgAl 2 o 4 / SSZ-13 nanomaterials, 15 parts of bentonite, 10 parts of magnesium oxide, and 20 parts of calcium carbonate were dispersed in 300 parts of absolute ethanol to form a mixed slurry, which was dried to obtain a composite sintering aid for later use;

[0033] Step 2. Add 30 parts of polymerized modified phenolic resin, 10 parts of silicon dioxide, 14 parts of boron nitride, 6 parts of hydroxymethyl cellulose, 10 parts of methyl acrylate and the composite sintering aid prepared in step 1 to the ball mill in sequence. 25 parts of the agent were wet ball milled, ball milled for 2 hours, vacuum stirred and defoamed, and ceramic slurry was prepared for subsequent use;

[0034] Step 3. Press the ceramic slurry prepared in the above steps into the mold from the bottom of the mold, place it naturally to complete the gel process, take out the ceramic green sheet and dry it at a temperature of 60°C for 2 hours, and then spread the ceramic green body i...

Embodiment 3

[0037] Step 1, 30 parts of MgAl 2 o 4 / SSZ-13 nanomaterials, 20 parts of bentonite, 10 parts of magnesium oxide, and 25 parts of calcium carbonate were dispersed in 300 parts of absolute ethanol to form a mixed slurry, which was dried to obtain a composite sintering aid for later use;

[0038] Step 2. Add 30 parts of polymerized modified phenolic resin, 10 parts of silicon dioxide, 14 parts of boron nitride, 6 parts of hydroxymethyl cellulose, 10 parts of methyl acrylate and the composite sintering aid prepared in step 1 to the ball mill in sequence. 25 parts of the agent were wet ball milled, ball milled for 2 hours, vacuum stirred and defoamed, and ceramic slurry was prepared for subsequent use;

[0039] Step 3. Press the ceramic slurry prepared in the above steps into the mold from the bottom of the mold, place it naturally to complete the gel process, take out the ceramic green sheet and dry it at a temperature of 60°C for 2 hours, and then spread the ceramic green body i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com