Multi-chamber heat accumulating type oxidation furnace

An oxidation furnace and regenerative technology, which is applied in the field of multi-chamber regenerative oxidation furnace, can solve the problems of RTO not being able to work continuously, difficulty in meeting national standards, and high emission concentration, achieving remarkable energy-saving effects, improving service life, and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

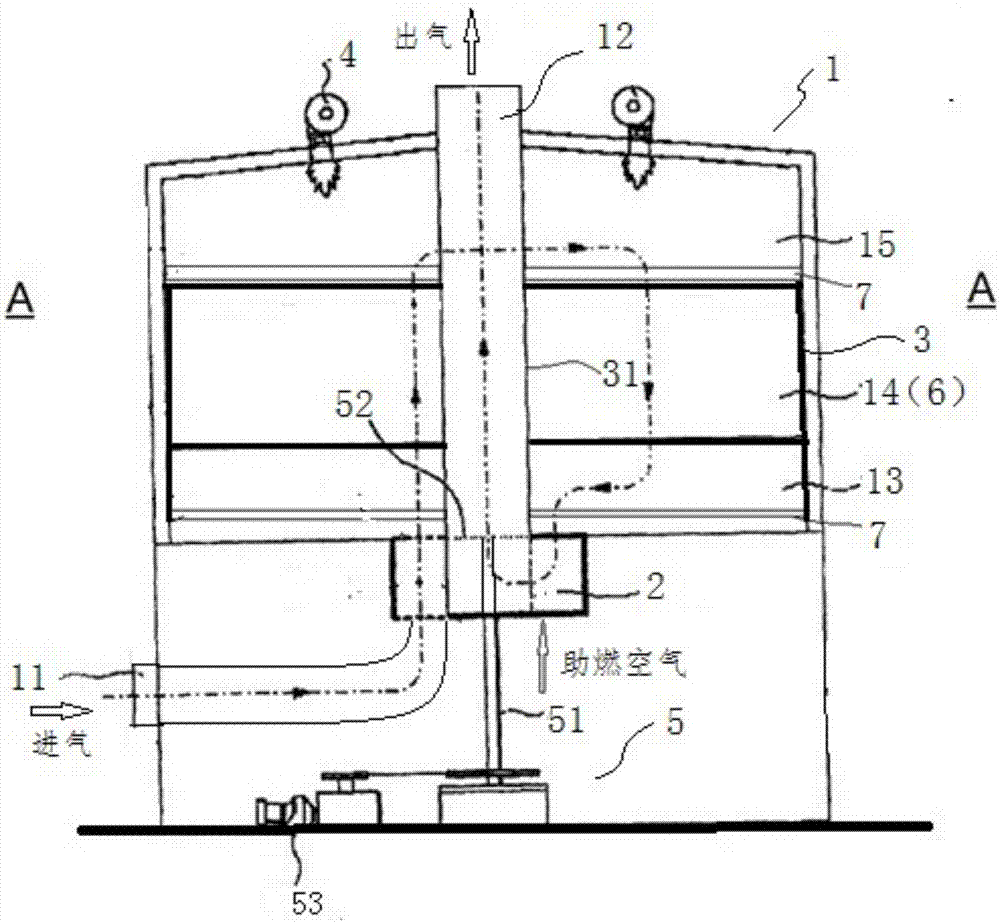

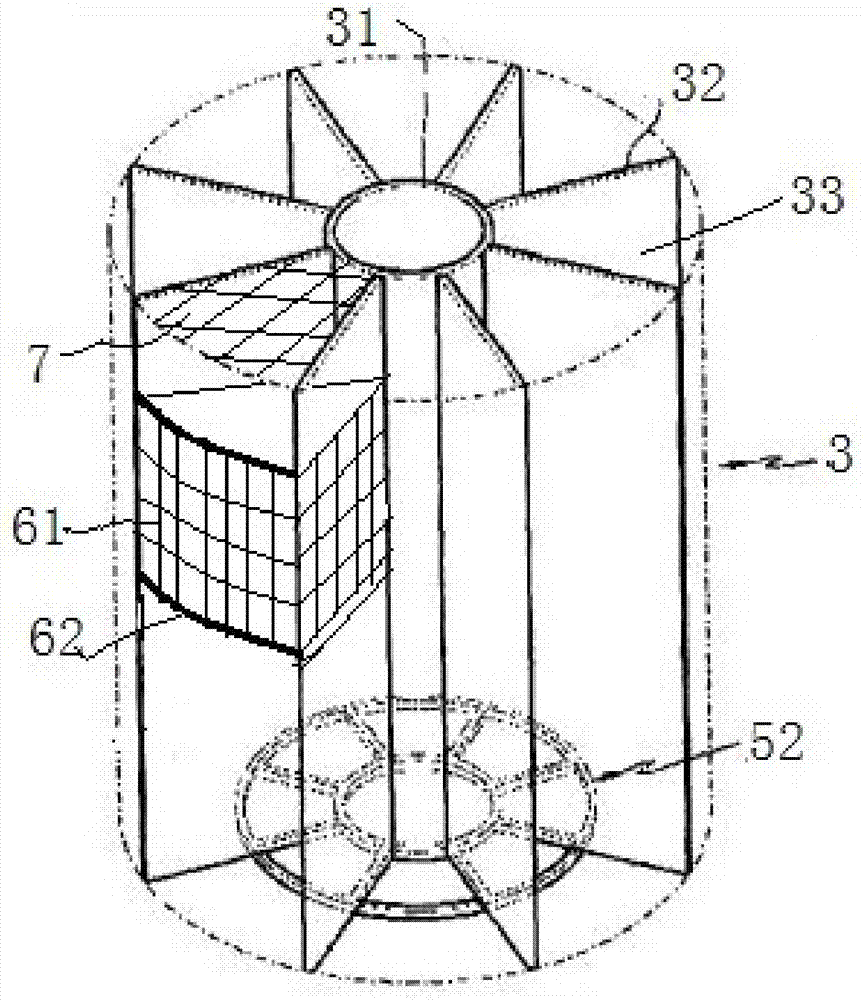

[0043] combine Figure 1 to Figure 4As shown, the embodiment discloses a multi-chamber regenerative oxidation furnace, which includes an oxidation furnace body 1, a gas distribution device 2, a segmentation device 3, a combustion-supporting device 4, a rotating device 5, a heat storage device 6 and a gas uniform distribution device 7.

[0044] Oxidation furnace body 1 is cylindrical structure, has an air intake pipe 11 and an exhaust pipe 12, and air intake pipe 11 is connected with the inlet end of oxidation furnace body 1, and exhaust pipe 12 is arranged in the middle of oxidation furnace body 1 top position and is connected to the gas outlet of the oxidation furnace body 1.

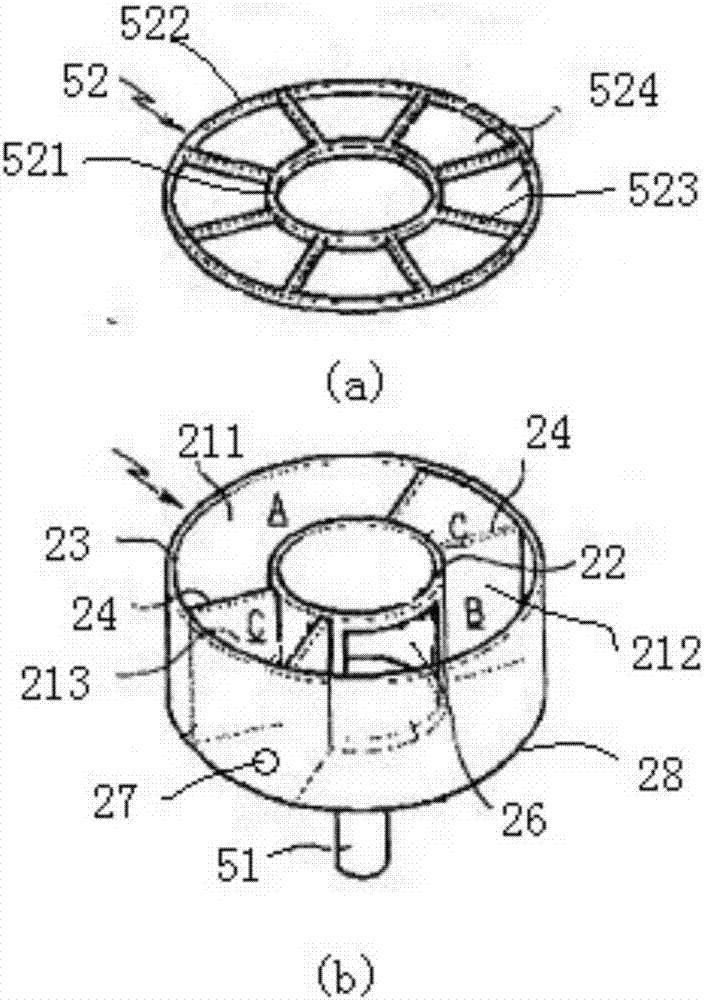

[0045] The gas distribution device 2 is fixed in the middle of the bottom surface of the oxidation furnace body 1. It is an inner and outer double-layer cylindrical structure with an open top surface, that is, the distribution inner cylinder 22 and the distribution outer cylinder 23. There are four pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com