An evaporative chiller and control method

A chiller and control method technology, which is applied in heating methods, mechanical equipment, lighting and heating equipment, etc., can solve the problems of slowing down scaling and low energy efficiency, and achieve the effects of improving cooling and heat release efficiency, increasing cooling capacity, and improving energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

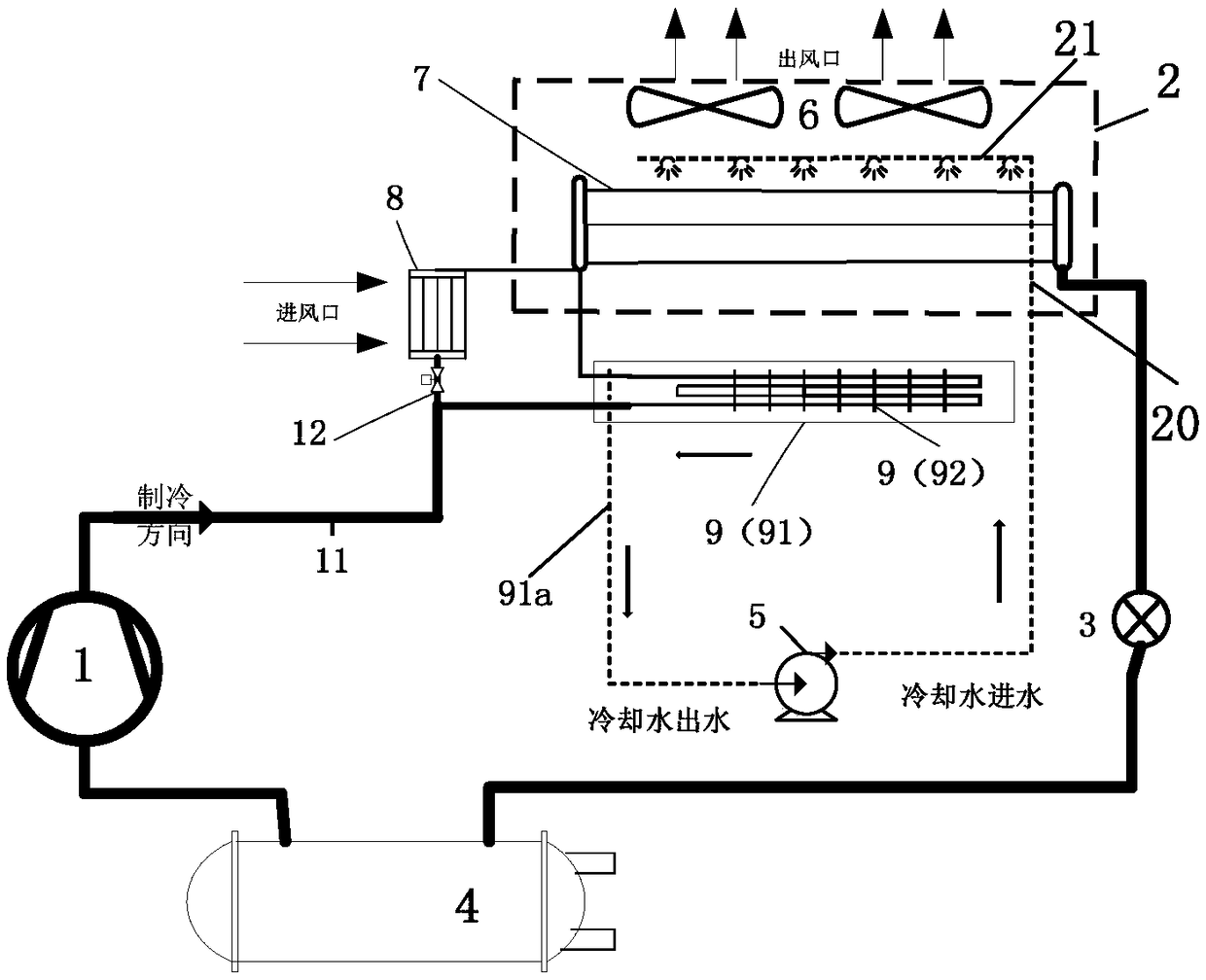

[0032] Such as figure 1 As shown, the present invention provides an evaporative water chiller, which includes:

[0033] Compressor 1 and evaporative condenser 2;

[0034] An air-cooled pre-cooling heat exchanger 8 is arranged between the compressor 1 and the evaporative condenser 2;

[0035] The water-cooled pre-cooling heat exchanger 9 is arranged between the compressor 1 and the evaporative condenser 2 and connected in parallel with the air-cooled pre-cooling heat exchanger 8 .

[0036] The invention solves the following technical problems: the applicability of the evaporative cooling unit is poor in high temperature and high humidity environment, the energy efficiency of high temperature and low humidity is poor, and the surface scaling of the heat exchanger is relatively serious, which causes the user to feel bad.

[0037] Through the water-cooled pre-cooling heat exchanger installed between the compressor and the evaporative condenser and in parallel with the air-cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com