Heating frock of narrow-gap clapboard welding and using method thereof

A narrow gap and tooling technology, applied in the field of welding processing, can solve the problems of too fast cooling of the weld seam, inability to heat up the weld seam, poor yield rate, etc., and achieve the effect of improving processing efficiency, increasing yield rate, and ensuring yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

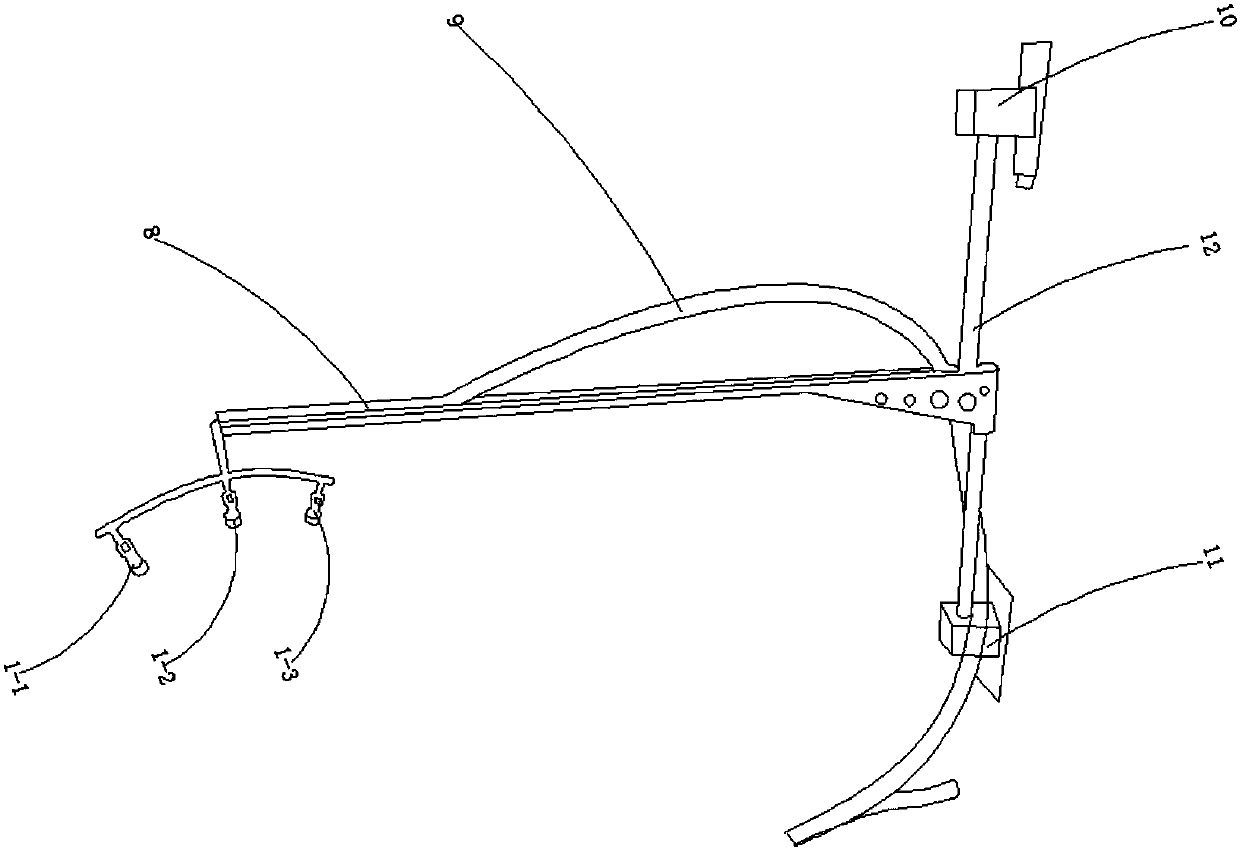

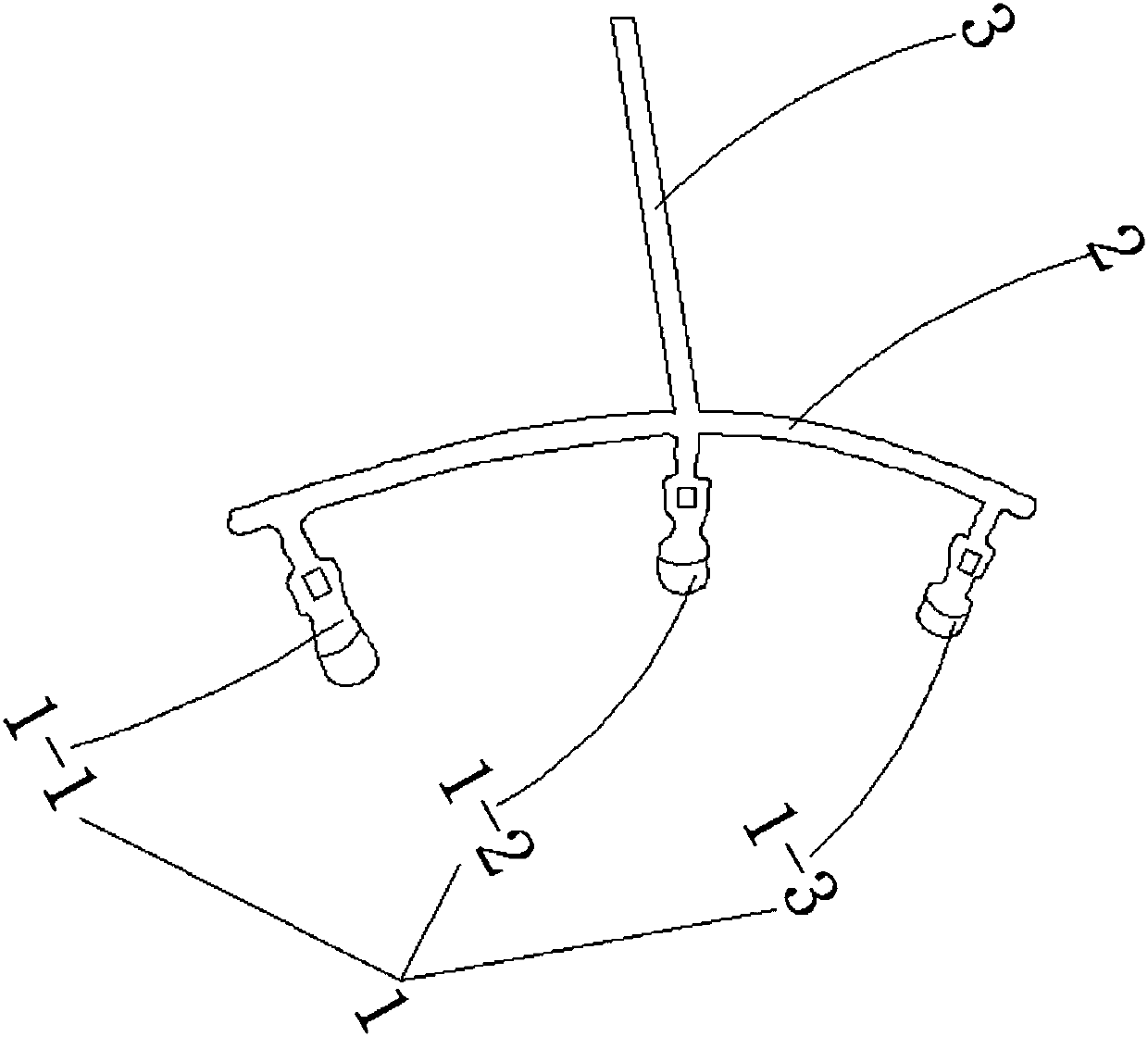

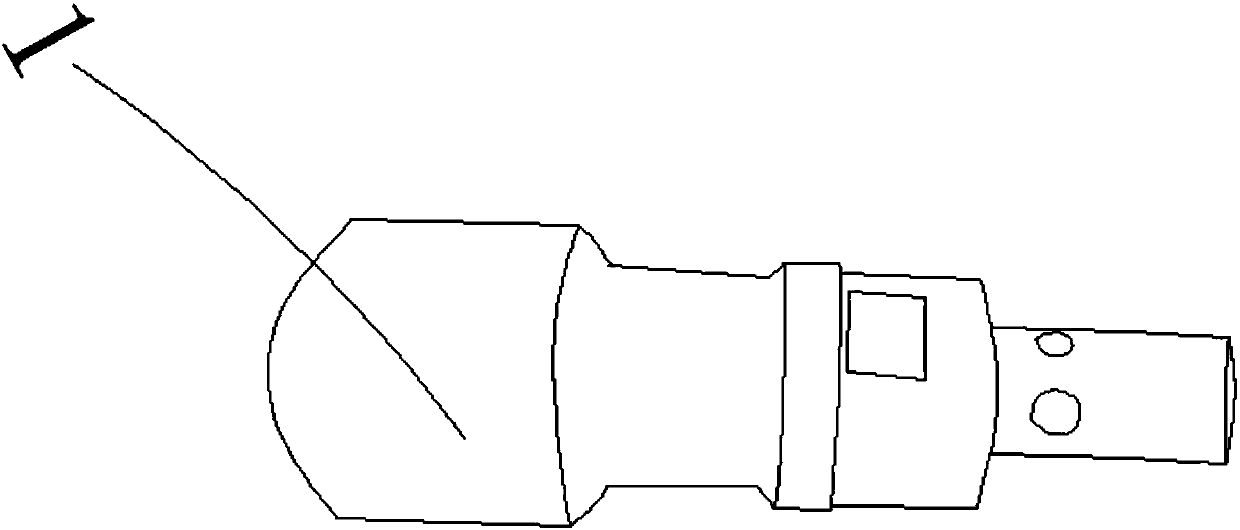

[0031] This embodiment provides a heating tool for narrow gap partition welding, which includes an arc support 2, a plurality of mounting holes arranged on the arc support 2, and a plurality of mounting holes are correspondingly equipped with three flame nozzles 1, which are connected to the circular arc support 2. The fixed frame 3 connected with the arc bracket 2, the ventilation pipe 9 connected with the flame nozzle 1, the link bracket 8 connected with the fixed frame 3, the link bracket 8 is used to fix the heating tool; the three flame nozzles 1 include the first nozzle Burner 1-1, the second burner 1-2, the third burner 1-3.

Embodiment 2

[0033] On the basis of the heating tooling for welding narrow-gap partitions in Embodiment 1, the arc of the arc support 2 is consistent with the arc of the workpiece;

[0034] The link bracket 8 is provided with a vent pipe hole for placing the vent pipe 9; the link bracket 8 is provided with a fixed installation hole, and an upper fixture 10 and a lower fixture 11 are arranged at a fixed position of the heating tool, so that A supporting rod 12 is arranged between the upper fixing part 10 and the lower fixing part 11, and the link bracket 8 is provided with a fixing installation hole to pass through the supporting rod 12 to realize fixing;

[0035] The fixed frame 3 is arranged at the middle position of the arc support 2 .

Embodiment 3

[0037] On the basis of the second embodiment, this embodiment provides a specific method for using the above-mentioned heating tool, including the following steps:

[0038] Step 1: place the processing workbench 6, and place the processing workpiece 4 on the workbench 6 correspondingly, wherein a fixing seat 7 is arranged under the workbench 6, wherein the workbench 6 is used for welding of steam turbine stator blades;

[0039] Step 2: According to the processing position of the workpiece 4, set the flame nozzle 1 on the arc support 2, connect the flame nozzle 1 with the ventilation pipe 9, connect the fixed frame 3 with the link bracket 8, and connect the link bracket 8 through the fixed installation The hole is fixed on the external fixing device, and the heating tooling 5 is fixed;

[0040] Step 3: During the welding process of the workpiece 4, use the heating tool 5 to heat the weld to be heated;

[0041] In the welding of steam turbine stator blades, due to the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com