High puncture strength and high polarity flame retardant waterproof sheet and preparation method thereof

A technology of waterproof sheet and puncture strength, which is applied in the field of high puncture resistance, high polarity flame retardant waterproof sheet and its preparation, and waterproof coiled material. Separate from the adhesive layer, use open flame, electric welding and other problems to avoid risks, improve bonding performance, and overcome the effects of non-refractory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

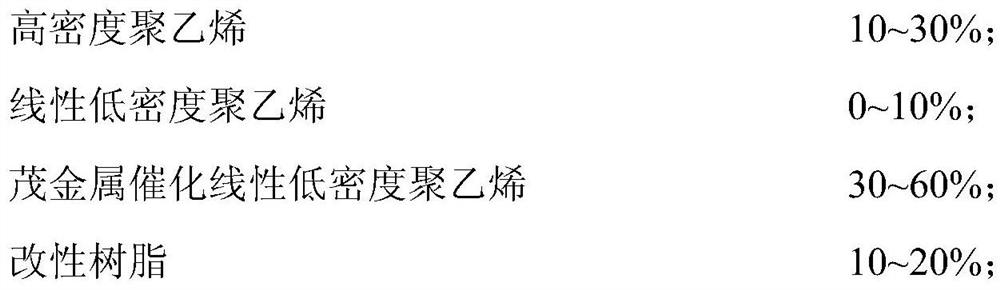

[0029] This embodiment provides a high puncture strength and high polarity flame-retardant waterproof sheet, its raw material composition and dosage refer to Table 1, wherein,

[0030] High-density polyethylene (HDPE): the density is 948kg / m 3 1. HDPE with a melt index of 10g / 10min comes from Qilu Petrochemical Company, and its brand name is 6098.

[0031] Linear Low Density Polyethylene (LLDPE): Density 920kg / m 3 , LLDPE with a melt index of 0.9g / 10min, from Shanghai Secco Company, the brand name is 0209AA.

[0032] Metallocene-catalyzed linear low-density polyethylene (MLLDPE): the density is 918kg / m 3 , MLLDPE with a melt index of 1.0g / 10min, from Exxon Mobil Corporation, the brand is 3518.

[0033] Modified resin: maleic anhydride grafted polyethylene, sourced from Nanjing Qiangren Plastic Co., Ltd., the brand is MHDPE.

[0034] Flame retardant: bromine-antimony flame retardant system, from Guangzhou Qiyuan New Material Co., Ltd., the brand is WT-S083.

[0035] The wa...

Embodiment 2

[0039] This example provides a flame-retardant waterproof sheet with high puncture strength and high polarity. Except for the following raw materials, the selection of other raw materials is the same as in Example 1. The dosage of each component is shown in Table 1. Among them,

[0040] High-density polyethylene (HDPE): the density is 950kg / m 3 , HDPE with a melt index of 0.8-1.2g / 10min, from Lanzhou Petrochemical Company, the brand is 5000S.

[0041] Linear Low Density Polyethylene (LLDPE): Density 920kg / m 3 , LLDPE with a melt index of 1.8g / 10min, from Lanzhou Petrochemical Company, the brand is 7042.

[0042] Metallocene-catalyzed linear low-density polyethylene (MLLDPE): the density is 927kg / m 3 1. MLLDPE with a melt index of 1.3g / 10min comes from Exxon Mobil Corporation, and its brand name is 1327HA.

[0043] Modified resin: maleic anhydride grafted ethylene-vinyl acetate copolymer, sourced from Nanjing Sutai Polymer Technology Co., Ltd., the brand is EVA-G-3.

[0044...

Embodiment 3

[0046] This example provides a flame-retardant waterproof sheet with high puncture strength and high polarity. Except for the following raw materials, the selection of other raw materials is the same as in Example 1. The dosage of each component is shown in Table 1. Among them,

[0047] Modified resin: chlorinated polyethylene, from Weifang Yaxing Chemical Co., Ltd., the brand is 5236.

[0048] The preparation method of the waterproof sheet is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com