Gas pipeline leakage detection and identification method based on optical fiber sensing data excavation

A technology for data mining and gas pipelines, applied in pipeline systems, data processing applications, character and pattern recognition, etc., can solve the problems of gas pipeline leak detection methods, gas pipeline leaks, leak detection difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

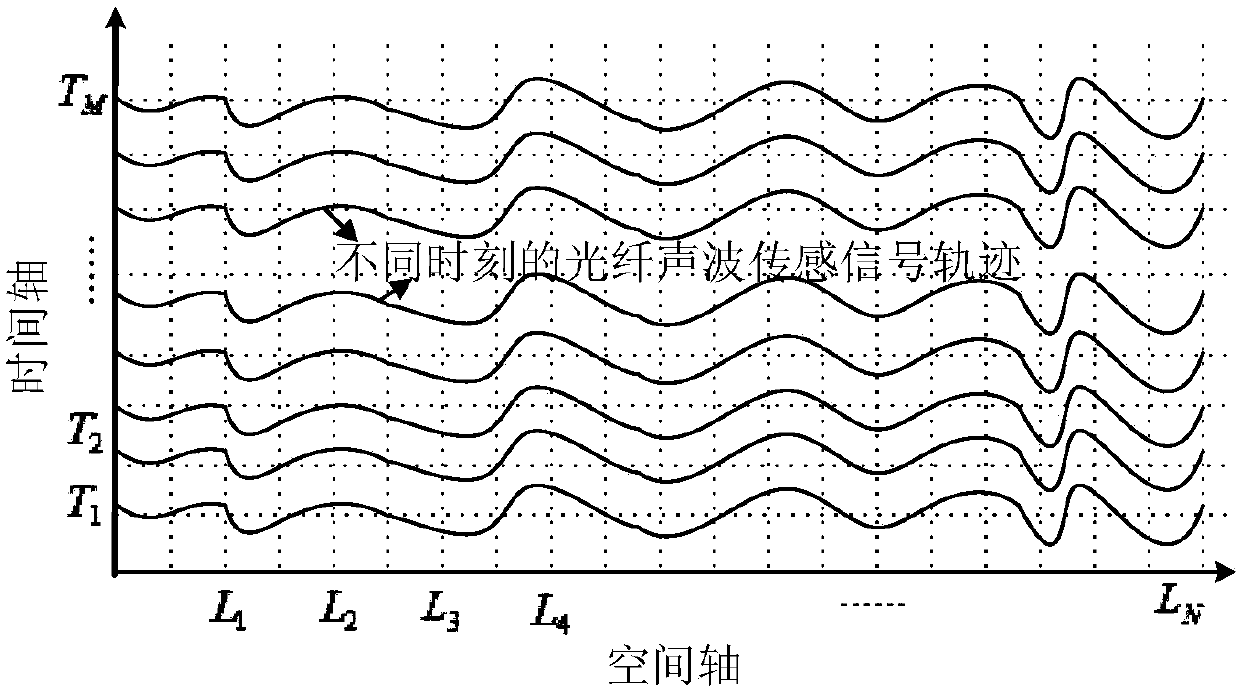

[0056] The gas pipeline online monitoring system based on distributed optical fiber acoustic / vibration sensing (DAS), the system hardware is mainly composed of three parts, detection optical cable, optical signal demodulation equipment, and signal processing host. The detection optical cable usually adopts ordinary single-mode communication optical fiber or acoustic wave and vibration-sensitized sensing optical cable, and is generally laid along the inner or outer wall of the gas pipeline. Optical signal demodulation equipment is the core of the system, and its internal components mainly include optical and electrical devices. In the demodulation equipment, the ultra-narrow linewidth laser emits a continuous optical signal and is modulated into an optical pulse by an acousto-optic / electro-optic modulator, which is then injected into the detection optical cable through an erbium-doped fiber amplifier (EDFA), a distributed Raman amplifier, an isolator, and a circulator. , the ba...

Embodiment 2

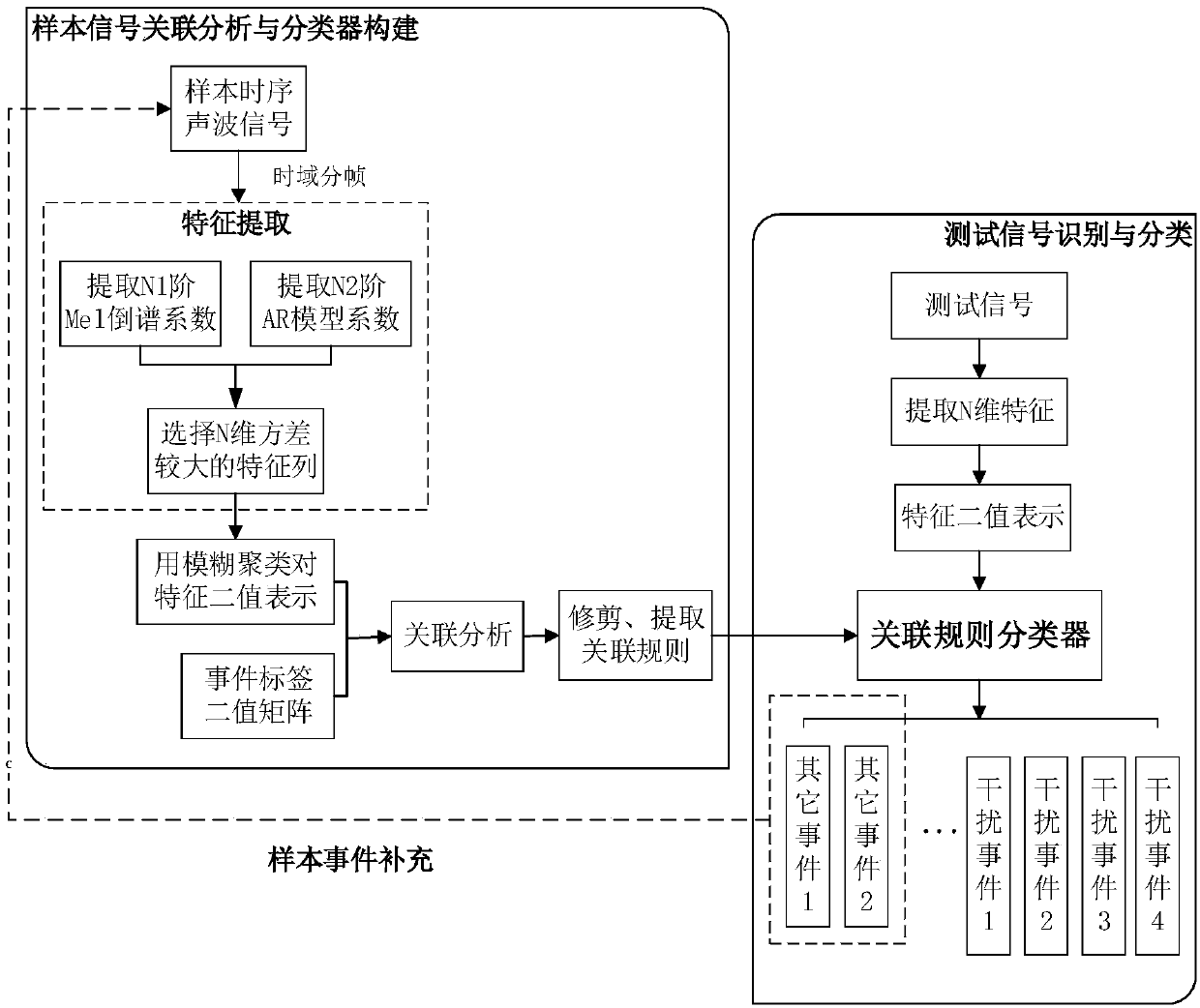

[0059] On the basis of Embodiment 1, the identification and classification of each space point leakage signal is the key of the present invention, and the specific process framework is as follows figure 2 As shown, it is divided into two parts: the first part is to mine association rules and classifier training based on the typical event database of gas pipelines, that is, to build an association rule classifier; the second part is to use the trained association rule classifier to analyze the pipeline leakage Perform online identification and classification.

Embodiment 3

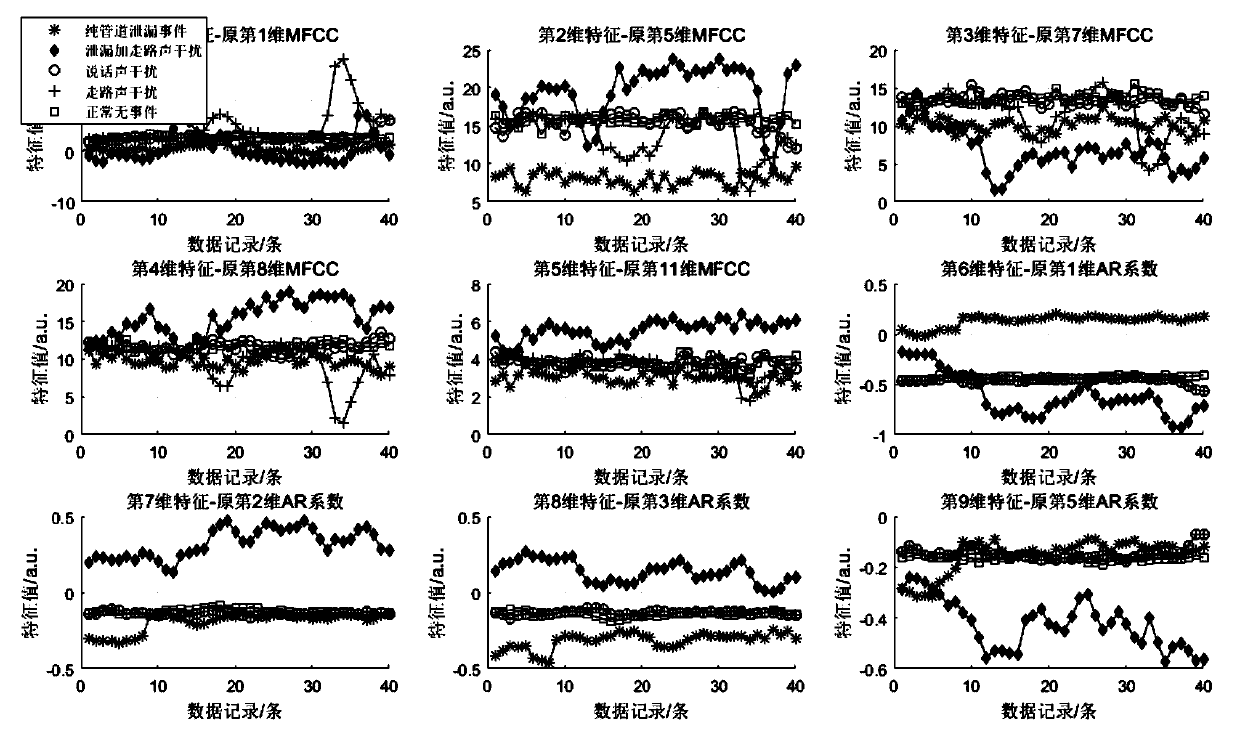

[0061] On the basis of Embodiment 2, based on the typical event types that actually occur in the gas pipeline, sample databases of different types of events are respectively constructed. The specific operation process is as follows: the time series collected within a certain space point within t seconds is processed in frames, and the Each frame time signal is placed in the sample database as a data record. For example, for a time series collected within k seconds t is the sampling time, which is a positive integer, f s is the time sampling frequency in Hz. Every q milliseconds is divided into one frame, and q is generally 20 to 80, so each frame contains (rounded) sampling points: XX={XX(m), m=1,2,...,M}. Sliding with time sequentially selects time series with a frame length of M in different time periods. In order to ensure the continuity of the data, an overlapping area of U sampling points is set for one section, and U generally takes the value of M or Therefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com