Modified lithium nickel cobalt manganese cathode material and production method thereof

A technology of lithium nickel cobalt manganese and cathode materials, applied in the field of lithium ion batteries, can solve the problems of poor storage performance, fast side reactions, large specific surface area, etc., and achieve the effects of high safety, high power density and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

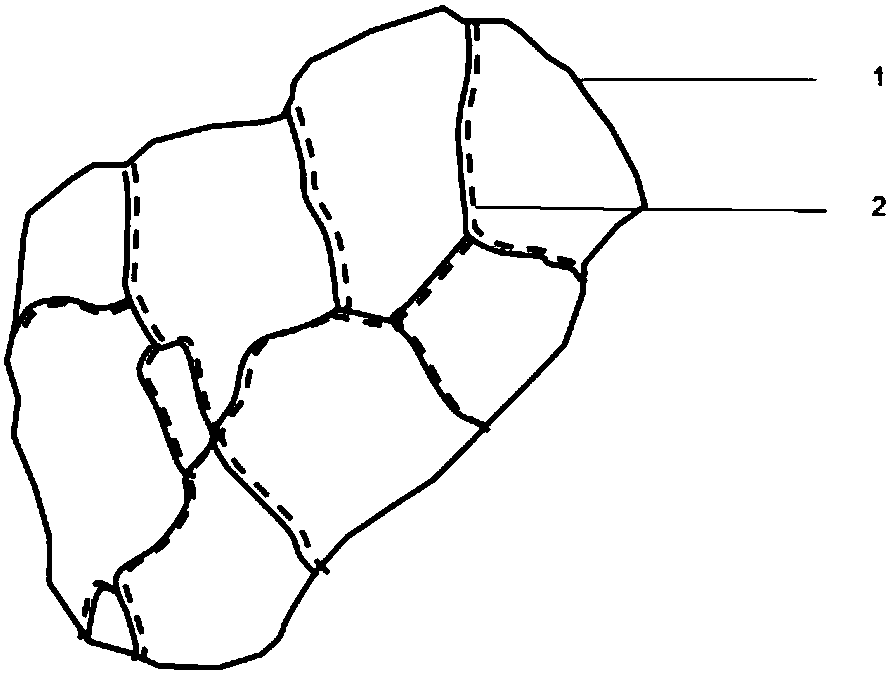

Image

Examples

preparation example Construction

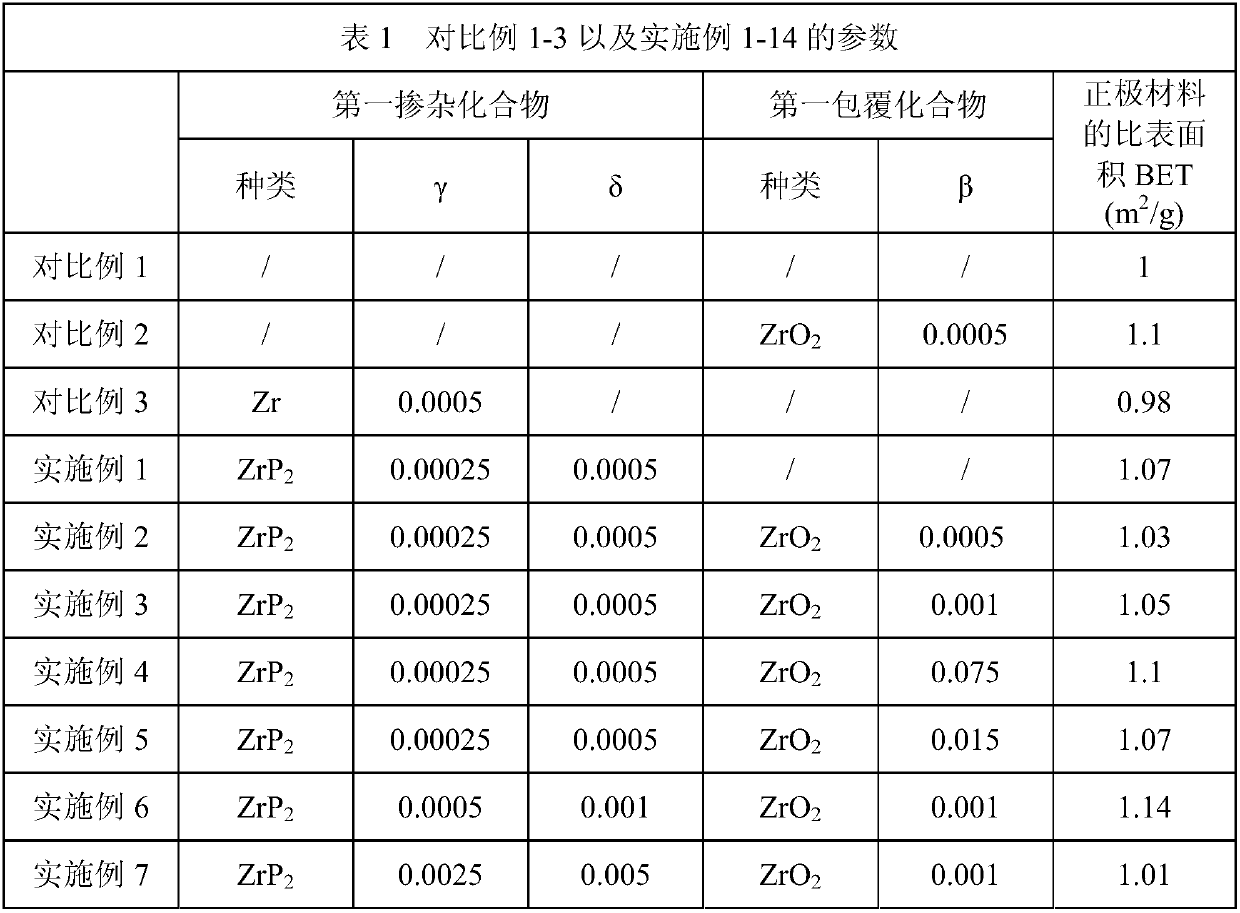

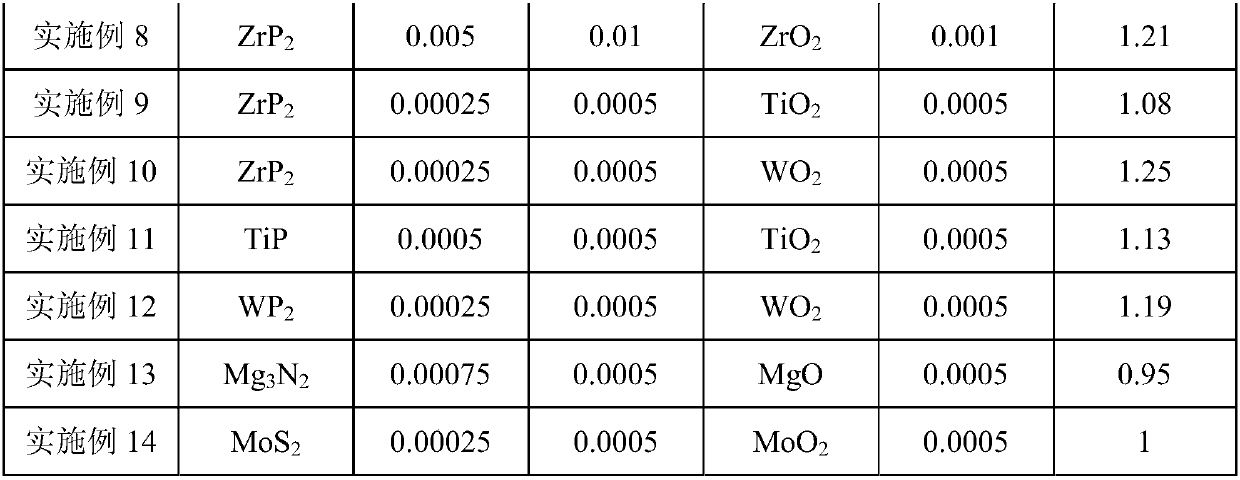

[0025] Next, the preparation method of the modified lithium-nickel-cobalt-manganese positive electrode material according to the second aspect of the present invention is described, which is used to prepare the modified lithium nickel-cobalt-manganese positive electrode material described in the first aspect of the present invention, comprising the steps of: (1) adding the nickel salt , cobalt salt, and manganese salt are made into a mixed solution according to the atomic ratio Ni:Co:Mn=x:y:z, and then are added dropwise to the reaction vessel together with the solution of the first doping compound for reaction, and are dried to obtain Precursor (Ni x co y mn z )(OH) 2 / M γ R δ , the first doping compound is selected from MR, MR 2 、MR 3 、MR 4 , M 3 R 2 , M 4 R 3 , M 2 R, M 2 R 3 One or more of them; (2) the precursor (Ni x co y mn z )(OH) 2 / M γ R δ It is evenly mixed with lithium salt according to the atomic ratio Li:(Ni+Co+Mn)=a:1, and then calcined to ob...

Embodiment 1

[0057] NiSO 4 、CoSO 4 , MnSO 4 According to the atomic ratio Ni:Co:Mn=0.35:0.35:0.30, a mixed aqueous solution is prepared, wherein the total concentration of cations is 2mol / L.

[0058] The mixed aqueous solution, 2mol / L NaOH solution, 3mol / L ammonia solution and the first doping compound ZrP 2 The aqueous dispersion liquid is added dropwise into the reaction vessel, the pH value of the system is controlled at 11.0±0.2, and the water bath is heated to 50° C. for the reaction. Among them, the first doping compound ZrP 2 The amount of addition is guaranteed to be based on the atomic ratio P:(Ni+Co+Mn)=0.0005:1 (ie δ=0.0005, γ=0.00025). Control the D50 of the precipitate to reach 3 μm to 4 μm, stop feeding, age for 2 hours, press filter, wash, and blast dry for 8 hours to obtain the precursor powder.

[0059] The obtained precursor powder was mixed with lithium salt Li 2 CO 3According to the atomic ratio Li:(Ni+Co+Mn)=1.1:1, the ball mill is evenly mixed, and placed in an...

Embodiment 2

[0061] NiSO 4 、CoSO 4 , MnSO 4 According to the atomic ratio Ni:Co:Mn=0.35:0.35:0.30, a mixed aqueous solution is prepared, wherein the total concentration of cations is 2mol / L.

[0062] The mixed aqueous solution, 2mol / L NaOH solution, 3mol / L ammonia solution and the first doping compound ZrP 2 The aqueous dispersion liquid is added dropwise into the reaction vessel, the pH value of the system is controlled at 11.0±0.2, and the water bath is heated to 50° C. for the reaction. Among them, the first doping compound ZrP 2 The amount of addition is guaranteed to be based on the atomic ratio P:(Ni+Co+Mn)=0.0005:1 (ie δ=0.0005, γ=0.00025). Control the D50 of the precipitate to reach 3 μm to 4 μm, stop feeding, age for 2 hours, press filter, wash, and blast dry for 8 hours to obtain the precursor powder.

[0063] The obtained precursor powder was mixed with lithium salt Li 2 CO 3 According to the atomic ratio Li:(Ni+Co+Mn)=1.1:1, the ball mill is evenly mixed, and placed in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com