Air dryer

An air dryer and cavity technology, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc. Convenient, simple and compact structure, the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

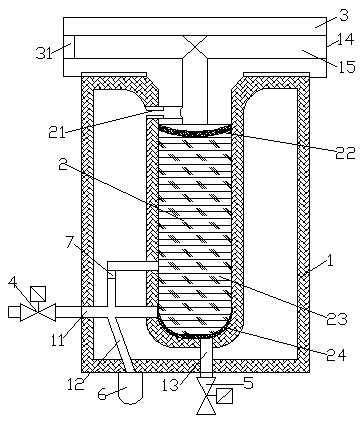

[0017] Such as figure 1 Shown is a schematic diagram of the overall structure of the present invention, an air dryer, including a shell 1 and an inner tank 2, a closed cavity is formed between the outer shell 1 and the inner tank 2, and a drying device is placed in the inner tank 2 agent 23, the inner tank 2 is provided with an air inlet, an air outlet and a waste discharge port, the air inlet is connected with an air inlet passage 11, and the air inlet passage 11 is fixedly equipped with a solenoid valve a4, the An oil filter element 7 is installed on the air intake passage 11, and the lower end of the air intake passage 11 is also fixedly connected with an oil collection passage 12, and the lower end of the oil co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com