A method for treating organic wastewater with laser-enhanced activated sludge

A technology for activated sludge and organic wastewater, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the difficulty of mud-water separation, poor treatment effect, poor dehydration effect, etc. problems, to achieve the effect of improving the structure of activated sludge, improving dehydration, and increasing the depth of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

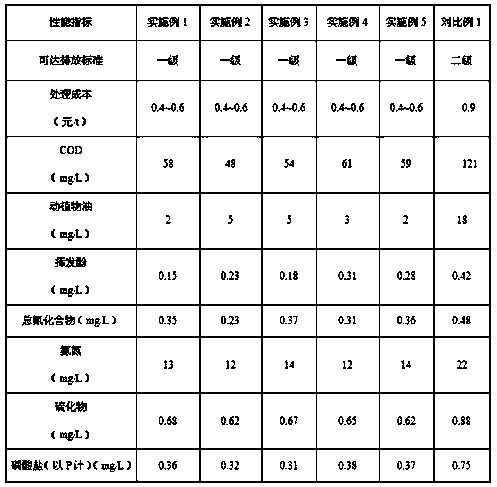

Examples

Embodiment 1

[0038] The treatment system is composed of primary sedimentation tank, aeration tank, laser system, oxygen supply system, secondary sedimentation tank, return system and residual sludge discharge system;

[0039] The culture process of activated sludge is as follows: (1) At the initial stage, aerate for 22h a day, stand for 2h, discharge 4L wastewater, and supplement the corresponding weight of self-allocated water to cultivate bacteria; (2) After 15d, aerate every day 10h, let stand for 2h, then aerate for 10h, let stand for 2h to cultivate protozoa such as micelles and bellworms; (3) After 30d, increase the influent COD and NH every 46h 3 -N concentration, gradually increase its NH 3 -N removal rate until it reaches more than 90% to increase the content of nitrifying bacteria and become qualified activated sludge;

[0040] The density of activated sludge is 1.005g / cm 3 , The particle size is 0.05mm, the specific surface area is 60cm 2 / cm 3 , The moisture content is 99.5%, the vol...

Embodiment 2

[0048] The treatment system is composed of primary sedimentation tank, aeration tank, laser system, oxygen supply system, secondary sedimentation tank, return system and residual sludge discharge system;

[0049] The culture process of activated sludge is as follows: (1) At the initial stage, aerate for 22h a day, stand for 2h, discharge 3L of wastewater, and supplement the corresponding weight of self-allocated water to cultivate bacteria; (2) After 14d, aerate every day 10h, let stand for 2h, then aerate for 10h, let stand for 2h to cultivate protists such as micelles and bellworms; (3) After 30d, increase the influent COD and NH every 44h 3 -N concentration, gradually increase its NH 3 -N removal rate until it reaches more than 90% to increase the content of nitrifying bacteria and become qualified activated sludge;

[0050] The density of activated sludge is 1.005g / cm 3 , The particle size is 0.2mm, the specific surface area is 80cm 2 / cm 3 , The water content is 99.7%, the vola...

Embodiment 3

[0058] The treatment system is composed of primary sedimentation tank, aeration tank, laser system, oxygen supply system, secondary sedimentation tank, return system and residual sludge discharge system;

[0059] The culture process of activated sludge is as follows: (1) At the initial stage, aerate for 22h every day, stand for 2h, discharge 3L of wastewater, and supplement the corresponding weight of self-allocated water to cultivate bacteria; (2) After 13d, aerate every day 10h, let stand for 2h, then aerate for 10h, let stand for 2h to cultivate protists such as micelles and bellworms; (3) After 28d, increase the influent COD and NH every 46h 3 -N concentration, gradually increase its NH 3 -N removal rate until it reaches more than 90% to increase the content of nitrifying bacteria and become qualified activated sludge;

[0060] The density of activated sludge is 1.002g / cm 3 , The particle size is 0.1mm, the specific surface area is 40cm 2 / cm 3 , The water content is 99.8%, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com