Multistage polymerization method and device of propylene

A polymerization method and propylene technology, applied in the field of polymer material preparation, can solve the problems of small difference in monomer composition, limited improvement of polymer mechanical properties and processing properties, etc., and achieve low volatile organic content, excellent mechanical properties, wide range Effect of Molecular Weight Distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

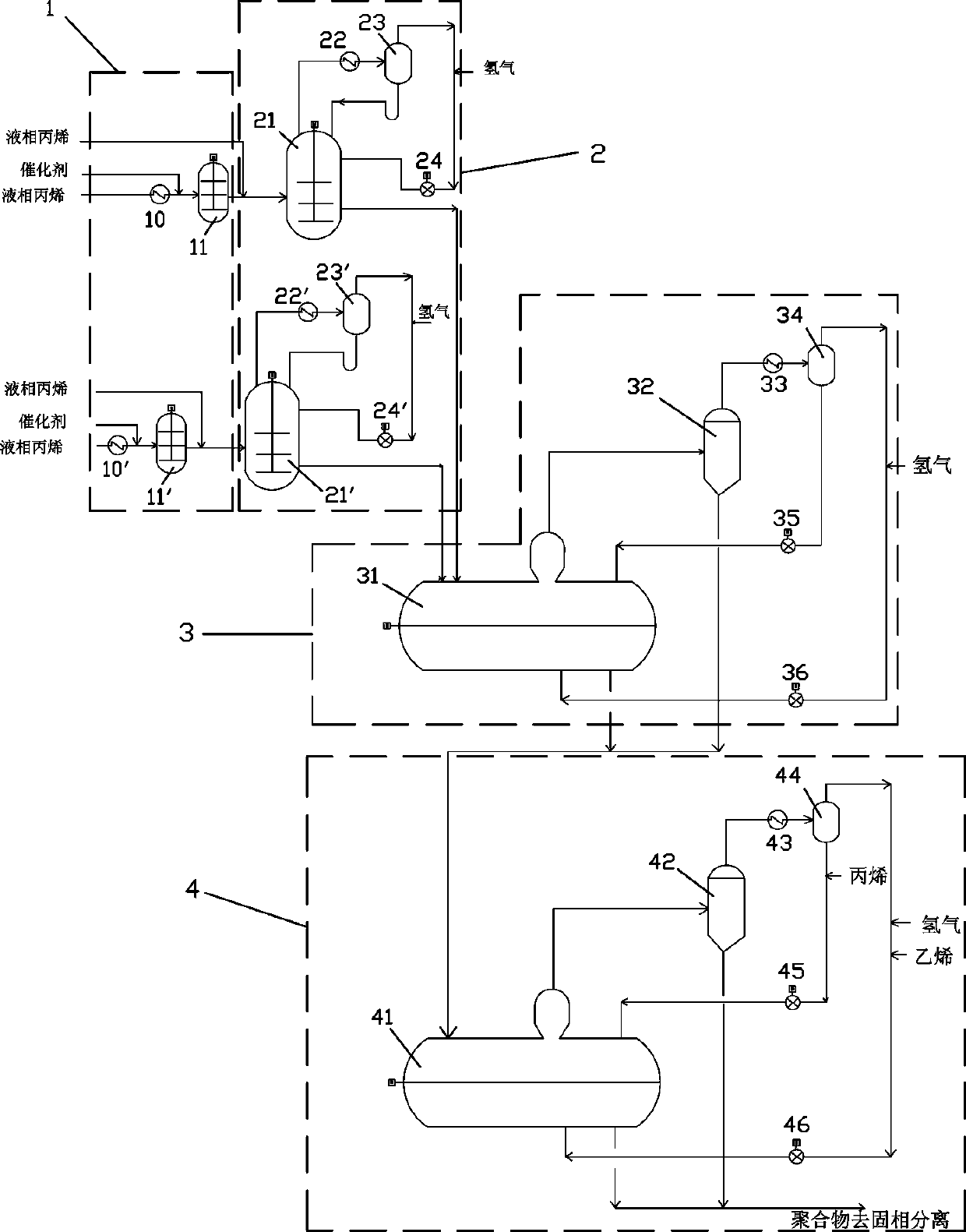

[0042] Example 1 see figure 1 , the propylene multi-stage polymerization device of the present invention, comprising:

[0043]The prepolymerization reaction unit 1 comprises two parallel prepolymerization reactors 11, 11', propylene coolers 10, 10' corresponding to the prepolymerization reactors, and the prepolymerization reactors 11, 11' are provided with material inlets and Outlet, the propylene cooler 10, 10' is connected to the material inlet of the prepolymerization reactor 11, 11';

[0044] Liquid-phase polymerization reaction unit 2, comprising two liquid-phase polymerization reactors 21, 21', two propylene condensers 22, 22', two liquid-separation tanks 23, 23' respectively corresponding to the two pre-polymerization reactors 11, 11' , two circulating air blowers 24, 24'; wherein, liquid phase polymerization reactor 21, 21' is provided with material inlet and outlet, gas phase propylene outlet, liquid phase propylene inlet, gas phase propylene inlet; liquid separation...

Embodiment 2

[0070] Example 2 The process of producing broad molecular weight distribution, high crystallization impact copolymer polypropylene is as follows:

[0071] Normal-temperature liquid-phase propylene (25°C, 3.5-4.5MPag) is cooled to 5-10°C through propylene coolers 10 and 10', and enters prepolymerization reactors 11 and 11' respectively. Carry out the prepolymerization reaction, wherein, the catalyst system A that can improve the molecular weight distribution of the polymer is added in the prepolymerization reactor 11, and the catalyst system B that improves the crystallinity of the polymer is added in the prepolymerization reactor 11', and the catalysts are all in the propylene polymerization reaction common catalysts.

[0072] The residence time of the catalyst in each pre-polymerization reactor is 12-17 minutes. The pre-polymerization reactor is operated with a full tank, and the catalyst and propylene are mixed evenly through the stirrer. The reaction temperature is 22-28 °C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com