Waterborne polyurethane resin and preparation method thereof

A water-based polyurethane and resin technology, applied in the field of water-based polyurethane, can solve the problems that hinder the development of water-based inks, cannot be reused, and high processing costs (costs, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

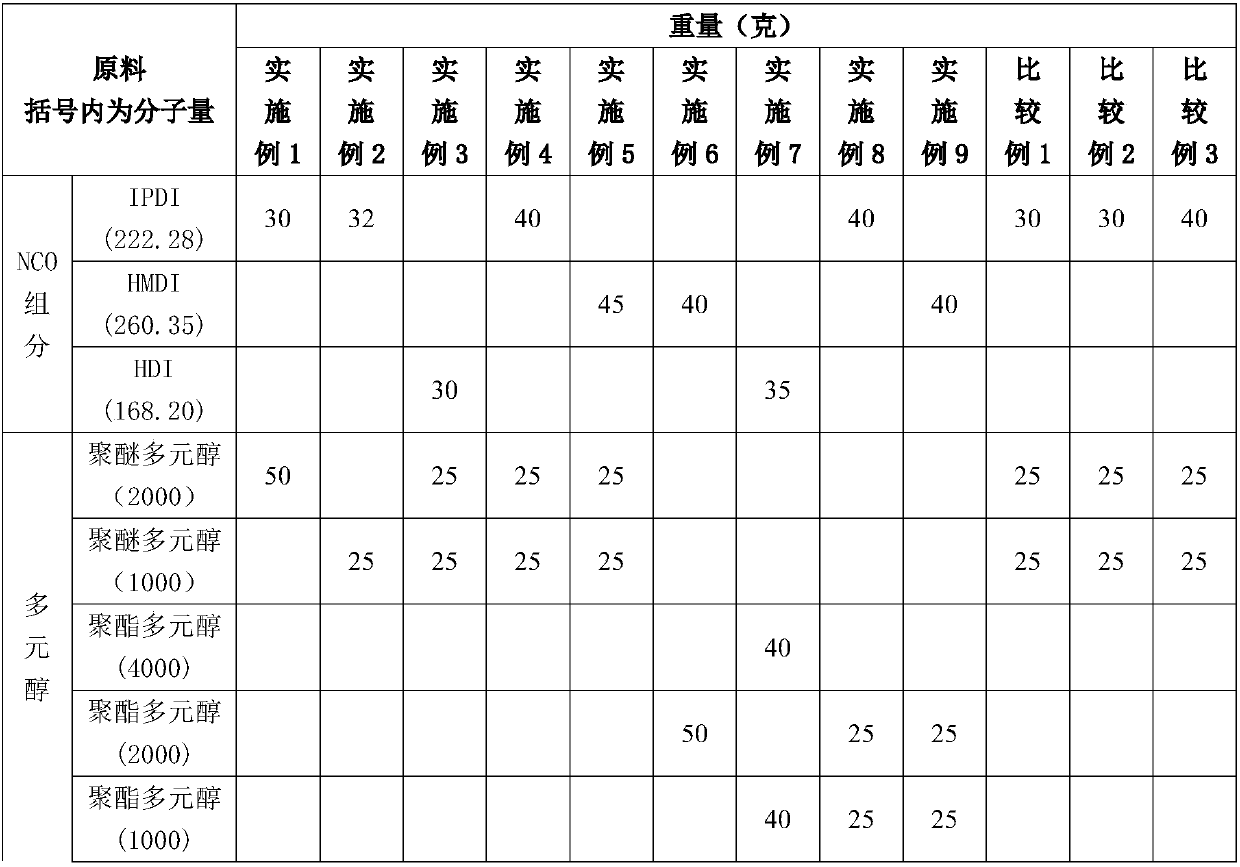

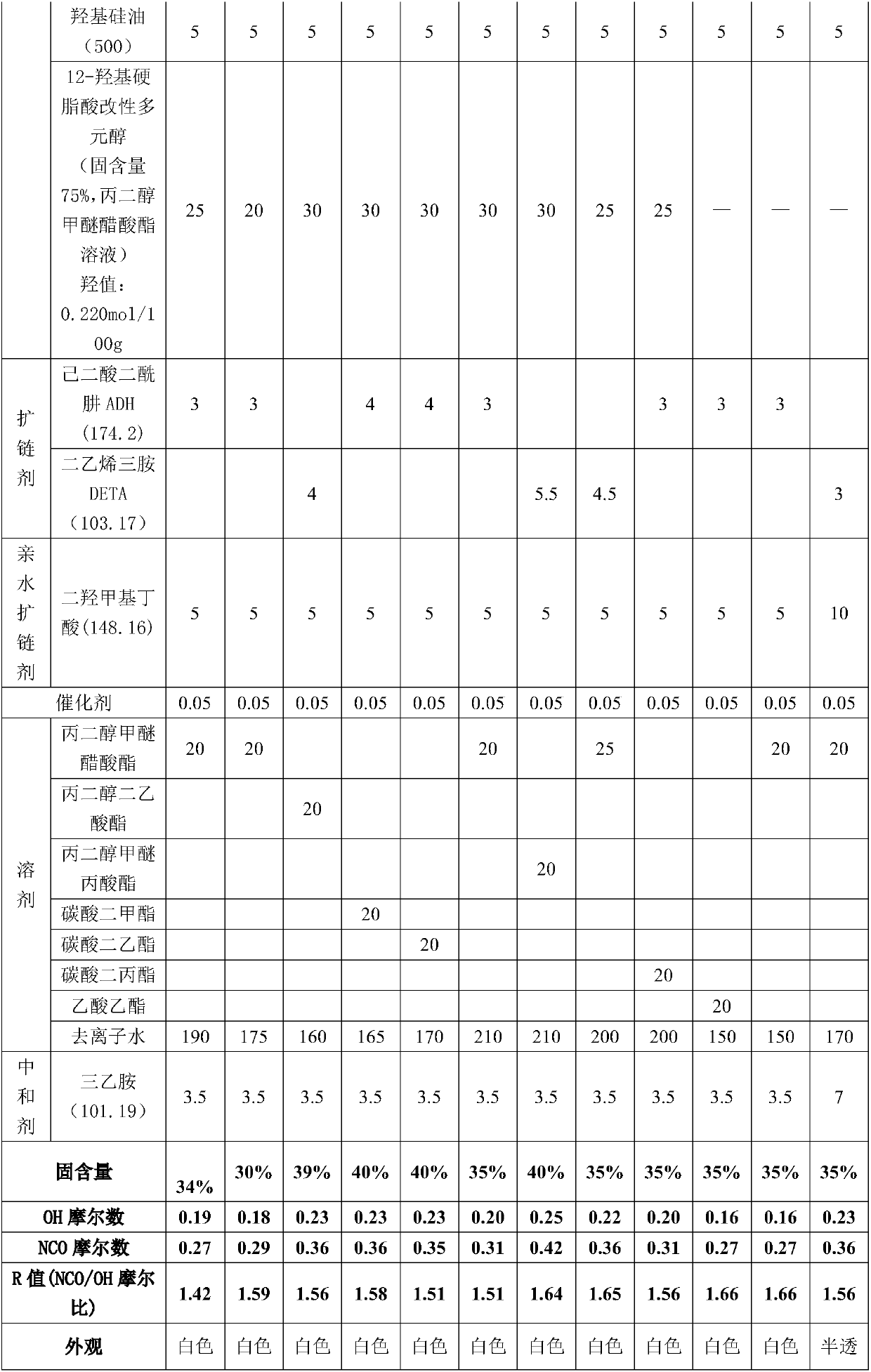

[0035] The following non-limiting examples illustrate the invention.

[0036]

[0037]

[0038]

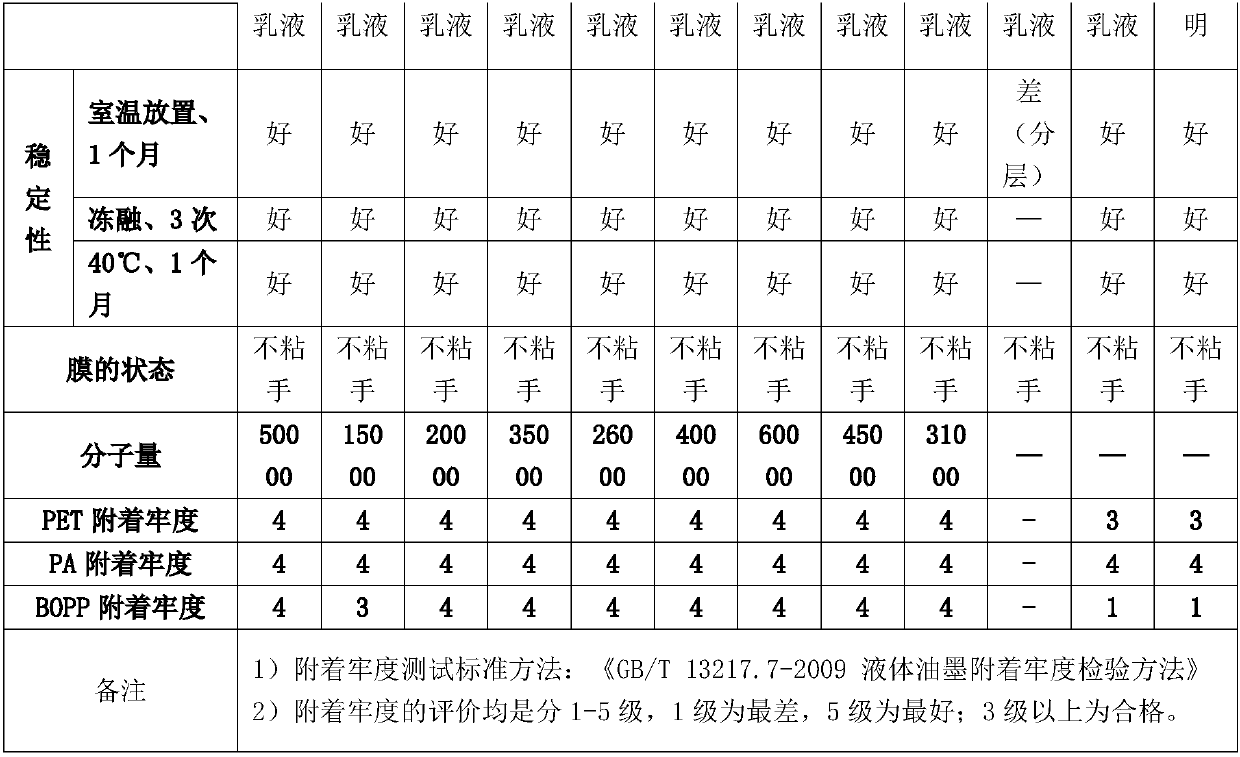

[0039] From above-mentioned embodiment and comparative example as can be known:

[0040] 1. This application uses propylene glycol methyl ether acetate as a solvent to prepare water-based polyurethane, which is more stable and does not require distillation to remove the solvent. Water-based polyurethane resin and its preparation method.

[0041] 2. This application uses self-made 12-hydroxystearic acid modified polyols to solve the problem of poor adhesion fastness of water-based polyurethane resin on plastic films. The prepared water-based polyurethane resin is commonly used in polyester PET, biaxially stretched Polypropylene BOPP, nylon PA and other plastic films, and has excellent adhesion. Wherein, the preferred weight part of 12-hydroxystearic acid modified polyol is 25-30 parts.

[0042] The preparation method of foregoing embodiment is:

[0043] Add conventional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com