A branched mud-suppressing polycarboxylate water reducer, its preparation method and application

A technology of mud polycarboxylate and water reducer, which is applied in the field of branched chain mud-suppressing polycarboxylate water reducer, which can solve the problems of not meeting the high fluidity requirements of concrete, failing to meet the working performance of concrete, and unsatisfactory use effects, etc. , to achieve strong designability, delay hydration and reunion, and facilitate popularization and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of branched-chain mud-suppressing polycarboxylate superplasticizer, the specific steps are as follows:

[0026] Step S1, performing free-radical polymerization of various unsaturated monomers to obtain a copolymer;

[0027] Step S2, introducing an unsaturated monomer with an amino group into the copolymer to perform an ammonia-epoxy reaction to obtain an intermediate;

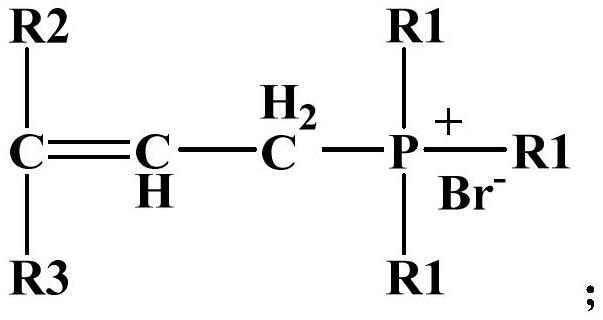

[0028] Step S3, introducing an unsaturated quaternary phosphorus salt compound into the intermediate to carry out a side chain growth reaction to prepare the branched mud-suppressing polycarboxylate superplasticizer.

[0029] According to the present invention, a copolymer is first synthesized. The various unsaturated monomers include small unsaturated epoxy monomers, small unsaturated ester monomers, small unsaturated sulfonic acid monomers, small unsaturated acid monomers, and unsaturated polyether macromonomers; At normal temperature (25°C), add the variou...

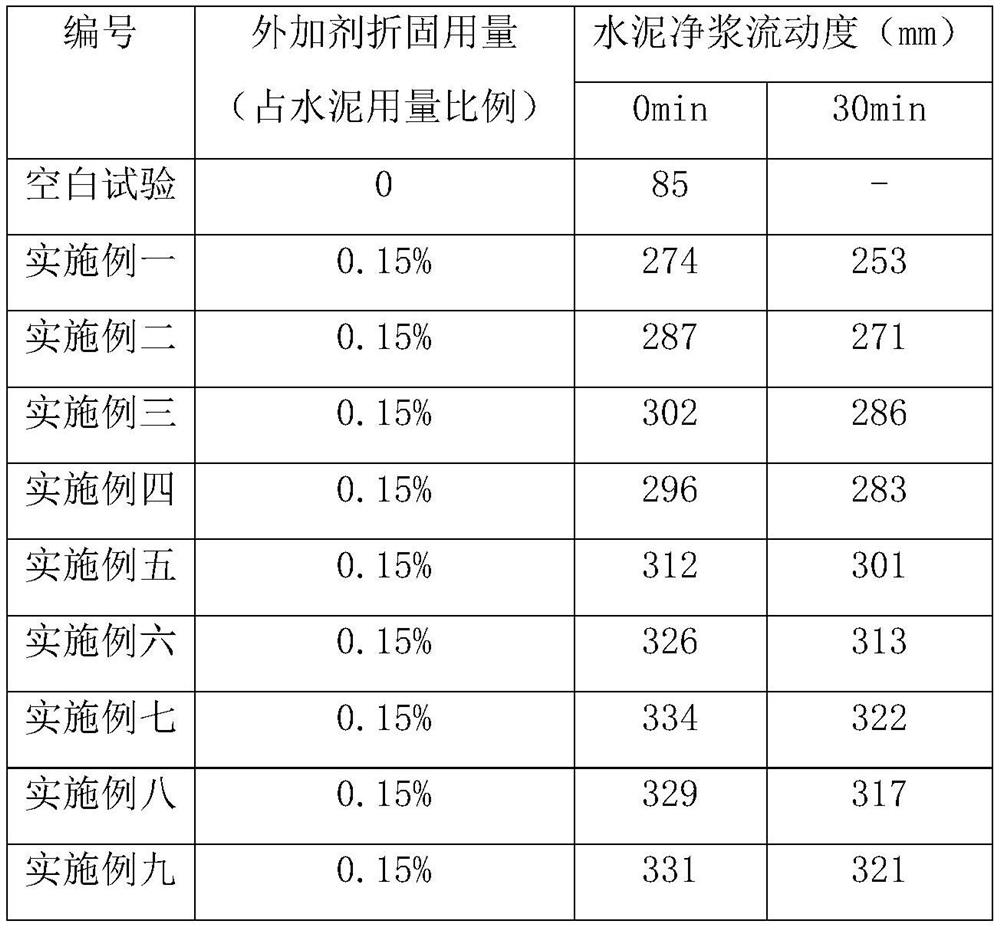

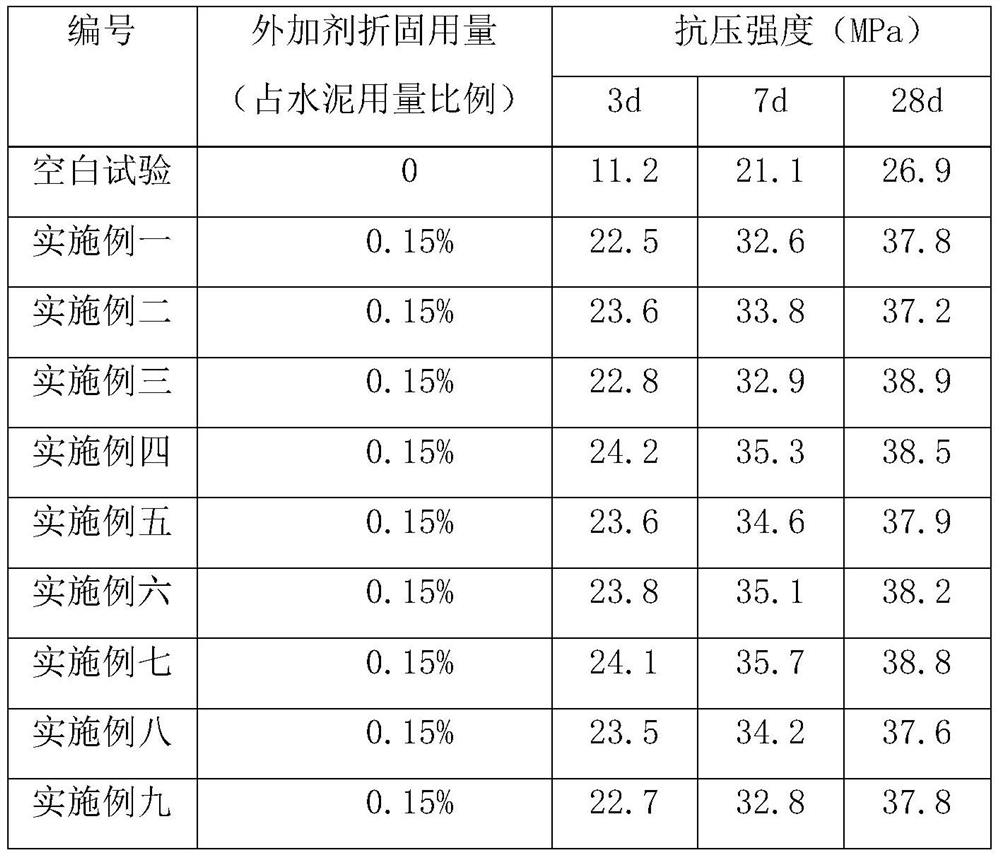

Embodiment 1

[0049] 1.1 At room temperature (25°C), weigh 1 g of the vinyl oxirane, 5 g of the methyl acrylate, 6 g of the allyl sulfonate amine, 5 g of the acrylic acid, and the methallyl Add 30g of alcohol polyoxyethylene ether into the four-necked flask, then add 50g of water and mix evenly; raise the temperature to 75°C, slowly add 21g of the first initiator solution dropwise to the four-necked flask, within 4h at a constant The speed of dropping is completed, and the reaction is continued at 75°C for 2 hours after the dropwise addition to obtain a copolymer;

[0050] 1.2 Add 1 g of the allylamine to the copolymer obtained in step 1.1, and react at 75° C. for 1 hour to obtain an intermediate;

[0051] 1.3 At the temperature above (75°C), add 2 g of the vinyl triphenylphosphine bromide to the intermediate, and then slowly add 5.1 g of the second initiator solution dropwise to the intermediate, the resulting The second initiator solution was dripped at a constant speed within 2 hours; a...

Embodiment 2

[0054] 2.1 At room temperature (25°C), weigh 1 g of the vinyl oxirane, 5 g of the methyl acrylate, 6 g of the allyl sulfonate amine, 5 g of the acrylic acid, and the methallyl Add 30g of alcohol polyoxyethylene ether into the four-necked flask, then add 50g of water and mix evenly; raise the temperature to 75°C, slowly add 21g of the first initiator solution dropwise to the four-necked flask, within 4h at a constant The speed of dropping is completed, and the reaction is continued at 75°C for 2 hours after the dropwise addition to obtain a copolymer;

[0055] 2.2 Add 1 g of the polyallylamine to the copolymer obtained in step 2.1, and react at 75° C. for 1 hour to obtain an intermediate;

[0056] 2.3 At the temperature above (75°C), add 4 g of vinyltriphenylphosphine bromide to the intermediate, and then slowly add 5.1 g of the second initiator solution dropwise to the intermediate, the resulting The second initiator solution was dripped at a constant speed within 2 hours; af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com