A polycarboxylate water reducer suitable for mud-containing aggregates and its preparation method

A technology of polycarboxylate and water reducer, which is applied in the field of preparation of polycarboxylate water reducer and polycarboxylate water reducer. To achieve the effect of enhancing steric hindrance, improving water reducing rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

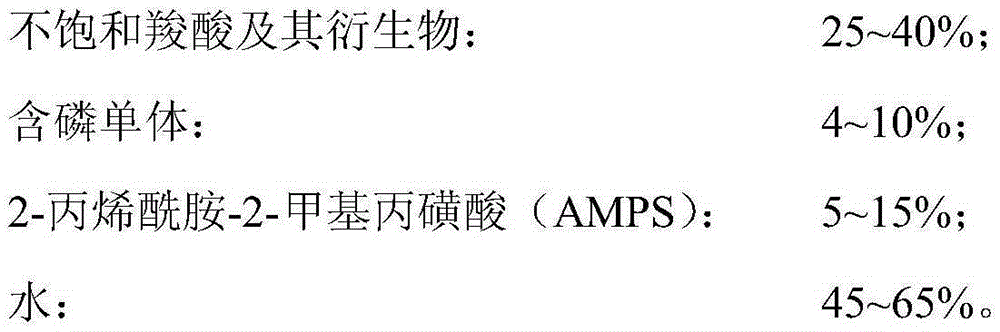

[0028] Step 1, the preparation of phosphonocarboxylic acid copolymer: 206 kilograms of acrylic acid and 95 kilograms of AMPS and 150 kilograms of water are made into dripping solution A, and 25 kilograms of sodium persulfate and 150 kilograms of water are made into dropping solution B for stand-by; Put 112 kg of maleic anhydride, 62 kg of sodium hypophosphite and 200 kg of water into a reaction kettle with a stirring paddle and a condensing reflux device, raise the temperature to 70°C, and add dropwise solution A and dropwise solution B at the same time, and finish dropping within 2 hours After dripping, the temperature was raised to 90°C and kept for 3 hours to obtain a phosphonocarboxylic acid copolymer PPC-1 with a solid content of 50%;

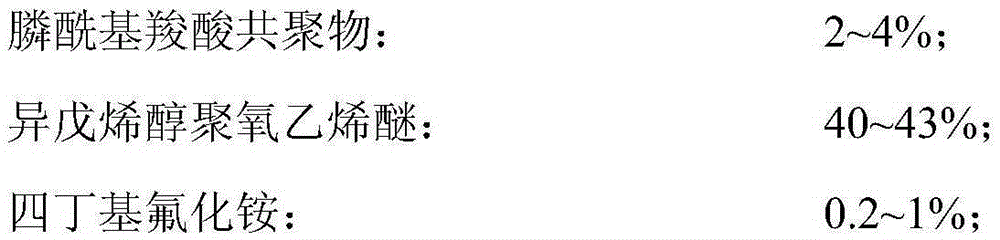

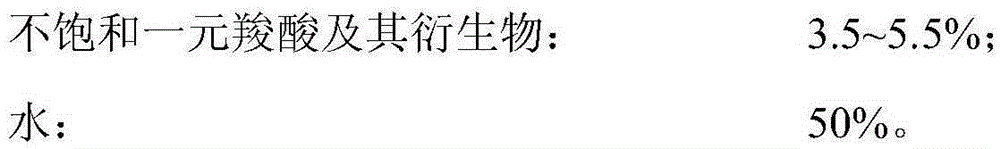

[0029] Step 2. Preparation of polycarboxylate water reducer suitable for mud-containing aggregates: 27.8 kg of phosphonocarboxylic acid copolymer PPC-1, 425.7 kg of isopentenol polyoxyethylene ether (average addition of ethylene oxide The ...

Embodiment 2

[0031] Step 1, the preparation of phosphonocarboxylic acid copolymer: 156 kilograms of acrylic acid, 113 kilograms of hydroxypropyl acrylate and 63 kilograms of AMPS and 150 kilograms of water are made into drop solution A, and 33 kilograms of sodium persulfate and 150 kilograms of water are made into drops Add liquid B for use; put 85 kg of fumaric anhydride, 50 kg of phosphorous acid and 200 kg of water into a reaction kettle with a stirring paddle and a condensing reflux device, raise the temperature to 70°C, and simultaneously add dropwise liquid A and dropwise liquid B, after 2 hours of dripping, the temperature was raised to 90° C. and kept for 3 hours after the dripping, to obtain a phosphonocarboxylic acid copolymer PPC-2, with a solid content of 50%;

[0032] Step 2. Preparation of polycarboxylate water reducer suitable for mud-containing aggregates: 32.1 kg of phosphonocarboxylic acid copolymer PPC-2, 416.6 kg of isopentenol polyoxyethylene ether (average addition of ...

Embodiment 3

[0034] Step 1, the preparation of phosphonocarboxylic acid copolymer: 190 kilograms of hydroxyethyl acrylate and 51 kilograms of AMPS and 150 kilograms of water are made into dripping solution A, 19 kilograms of ammonium persulfate and 150 kilograms of water are made into dropping solution B to be prepared Use; put 160 kg of fumaric anhydride, 80 kg of sodium hypophosphite and 200 kg of water into a reactor with a stirring paddle and a condensing reflux device, raise the temperature to 70°C, and simultaneously add dropwise liquid A and dropwise liquid B, 2 After hours of dripping, the temperature was raised to 90° C. and incubated for 3 hours to obtain a phosphonocarboxylic acid copolymer PPC-3 with a solid content of 50%;

[0035] Step 2. Preparation of polycarboxylate water reducer suitable for mud-containing aggregates: 36 kg of phosphonocarboxylic acid copolymer PPC-3, 402.5 kg of isopentenol polyoxyethylene ether (average addition of ethylene oxide The number of moles is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com