Fermented soybean and preparation method thereof

A technology for tempeh and soybeans, which is applied in the fields of food science, food preservation, application, etc., can solve the problems of reducing the nutritional value and sensory effect of tempeh, poor quality preservation effect, easy deterioration of tempeh, etc., so as to improve the nutritional content and sensory effect, and achieve a long shelf life. , The effect of improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

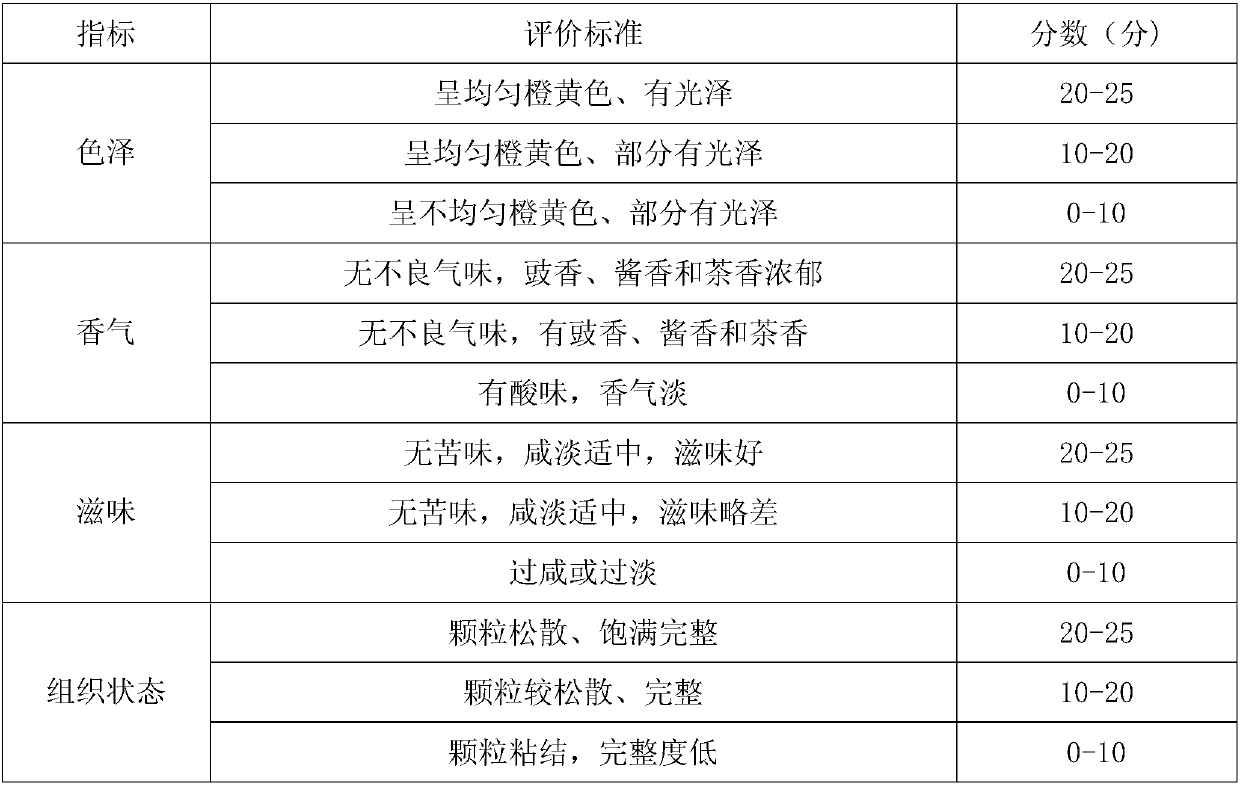

Image

Examples

Embodiment 1

[0026] 1. Preparation before preparation

[0027] 1) Preparation of excipients

[0028] S1: In parts by weight, weigh 3 parts of ginger, 2 parts of tangerine peel, 1 part of garlic, 1 part of pepper, 1 part of star anise and 3 parts of table salt;

[0029] S2: Grind and sieve the weighed raw material components to 200 meshes, then dry-fry the ginger, tangerine peel, garlic, pepper and star anise until the aroma comes out, then cool to room temperature, add salt and stir until evenly mixed , to obtain the auxiliary materials and set aside.

[0030] 2) Preparation of coating film

[0031] S1: In parts by weight, weigh 2 parts of soybean protein isolate, 1 part of chitosan, 0.5 part of sodium alginate, 0.3 part of whey protein, 3 parts of corn starch, 0.2 part of perilla extract and 0.3 part of licorice extract ;

[0032] S2: After gelatinizing the cornstarch, add the rest of the raw materials and mix them uniformly to obtain a mixed raw material, mix and stir the mixed raw m...

Embodiment 2

[0046] 1. Preparation before preparation

[0047] 1) Preparation of excipients

[0048] S1: In parts by weight, weigh 4 parts of ginger, 3 parts of tangerine peel, 2 parts of garlic, 2 parts of pepper, 2 parts of star anise and 4 parts of table salt;

[0049] S2: Grind and sieve the weighed raw material components to 200 meshes, then dry-fry the ginger, tangerine peel, garlic, pepper and star anise until the aroma comes out, then cool to room temperature, add salt and stir until evenly mixed , to obtain the auxiliary materials and set aside.

[0050] 2) Preparation of coating film

[0051] S1: In parts by weight, weigh 4 parts of soybean protein isolate, 2.3 parts of chitosan, 0.9 part of sodium alginate, 0.6 part of whey protein, 4 parts of corn starch, 0.4 part of perilla extract and 0.4 part of licorice extract ;

[0052] S2: After gelatinizing the cornstarch, add the rest of the raw materials and mix them evenly to obtain a mixed raw material. Mix the mixed raw materia...

Embodiment 3

[0066] 1. Preparation before preparation

[0067] 1) Preparation of excipients

[0068] S1: In parts by weight, weigh 5 parts of ginger, 5 parts of tangerine peel, 3 parts of garlic, 3 parts of pepper, 3 parts of star anise and 5 parts of table salt;

[0069] S2: Grind and sieve the weighed raw material components to 200 meshes, then dry-fry the ginger, tangerine peel, garlic, pepper and star anise until the aroma comes out, then cool to room temperature, add salt and stir until evenly mixed , to obtain the auxiliary materials and set aside.

[0070] 2) Preparation of coating film

[0071] S1: In parts by weight, weigh 6 parts of soybean protein isolate, 3 parts of chitosan, 1.5 parts of sodium alginate, 0.8 parts of whey protein, 5 parts of corn starch, 0.6 parts of perilla extract and 0.6 part of licorice extract ;

[0072] S2: After gelatinizing the cornstarch, add the rest of the raw materials and mix them uniformly to obtain a mixed raw material, mix and stir the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com