Resin adsorption synthesis technology for extracting tea polyphenols from discarded fresh tea leaves

A technology of resin adsorption and fresh tea leaves, which is applied in the direction of drug combination, medical preparations containing active ingredients, antidote, etc., can solve the problem of low extraction efficiency, strict technical requirements for separation and purification of tea polyphenols, incomplete extraction of tea polyphenols, etc. problem to achieve efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

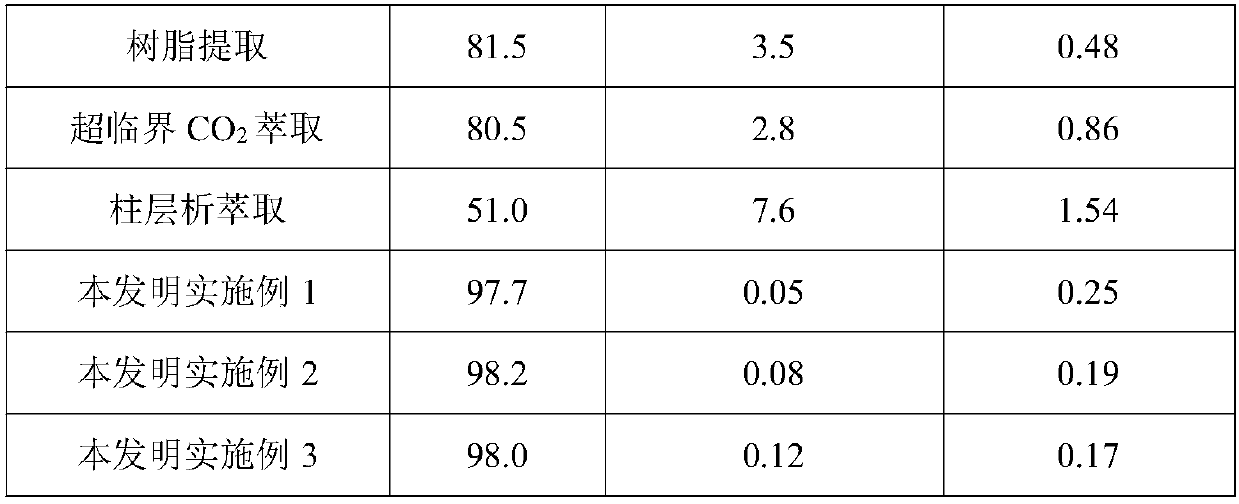

Embodiment 1

[0040] A resin adsorption comprehensive technology for extracting tea polyphenols from discarded fresh tea leaves, comprising the following steps:

[0041] (1) Coarse separation of impurities:

[0042] A1: Wash the discarded fresh tea leaves with a tea washing machine, then heat the tea leaves to 280°C with microwaves, and keep them for 3 minutes to inactivate enzymes;

[0043] A2: Extract waste fresh tea leaves in boiling water, crush them with a dumb jaw crusher, cut and crush the tea leaves to a mesh size of 110-120 mesh, filter, repeat more than two times, and combine the filtrates;

[0044] A3: Use 95% chloroform and 5% petroleum ether mixture to extract the filtrate, separate the layers, remove the chloroform petroleum ether extraction layer, and keep the aqueous solution layer;

[0045] A4: repeat step A3 twice, and combine the aqueous solution layer;

[0046] A5: Maintain the temperature at 35-40°C to stir and evaporate the aqueous solution layer under negative press...

Embodiment 2

[0060] A resin adsorption comprehensive technology for extracting tea polyphenols from discarded fresh tea leaves, comprising the following steps:

[0061] (1) Coarse separation of impurities:

[0062] A1: Wash the discarded fresh tea leaves with a tea washing machine, then heat the tea leaves to 260°C with microwaves, and keep them for 4 minutes to inactivate enzymes;

[0063] A2: Extract waste fresh tea leaves in boiling water, crush them with a hammer mill, cut and crush the tea leaves to a mesh size of 180-230 mesh, filter, repeat more than two times, and combine the filtrates;

[0064] A3: Use 97% chloroform and 3% petroleum ether mixture to extract the filtrate, separate the layers, remove the chloroform petroleum ether extraction layer, and keep the aqueous solution layer;

[0065] A4: repeat step A3 twice, and combine the aqueous solution layer;

[0066] A5: Maintain the temperature at 35-40°C to stir and evaporate the aqueous solution layer under negative pressure;

...

Embodiment 3

[0080] A resin adsorption comprehensive technology for extracting tea polyphenols from discarded fresh tea leaves, comprising the following steps:

[0081] (1) Coarse separation of impurities:

[0082] A1: Clean the discarded fresh tea leaves with a tea washing machine, and then heat the tea leaves to 270°C with microwaves for 3.5 minutes to inactivate enzymes;

[0083] A2: Extract waste fresh tea leaves in boiling water, crush them with an ultrafine pulverizer, cut and crush the tea leaves to a mesh size of 240-280 mesh, filter, repeat more than two times, and combine the filtrates;

[0084] A3: Use 99% chloroform and 1% petroleum ether mixture to extract the filtrate, separate the layers, remove the chloroform petroleum ether extraction layer, and keep the aqueous solution layer;

[0085] A4: repeat step A3 twice, and combine the aqueous solution layer;

[0086] A5: Maintain the temperature at 35-40°C to stir and evaporate the aqueous solution layer under negative pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com