Preparation method of anglerfish bone biochar material capable of adsorbing heavy metal

A technology for adsorbing heavy metals and biochar, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problems of waste of resources, pollution of the environment, etc., and achieve small average particle size, high specific surface area, and adsorption The effect of high efficiency of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

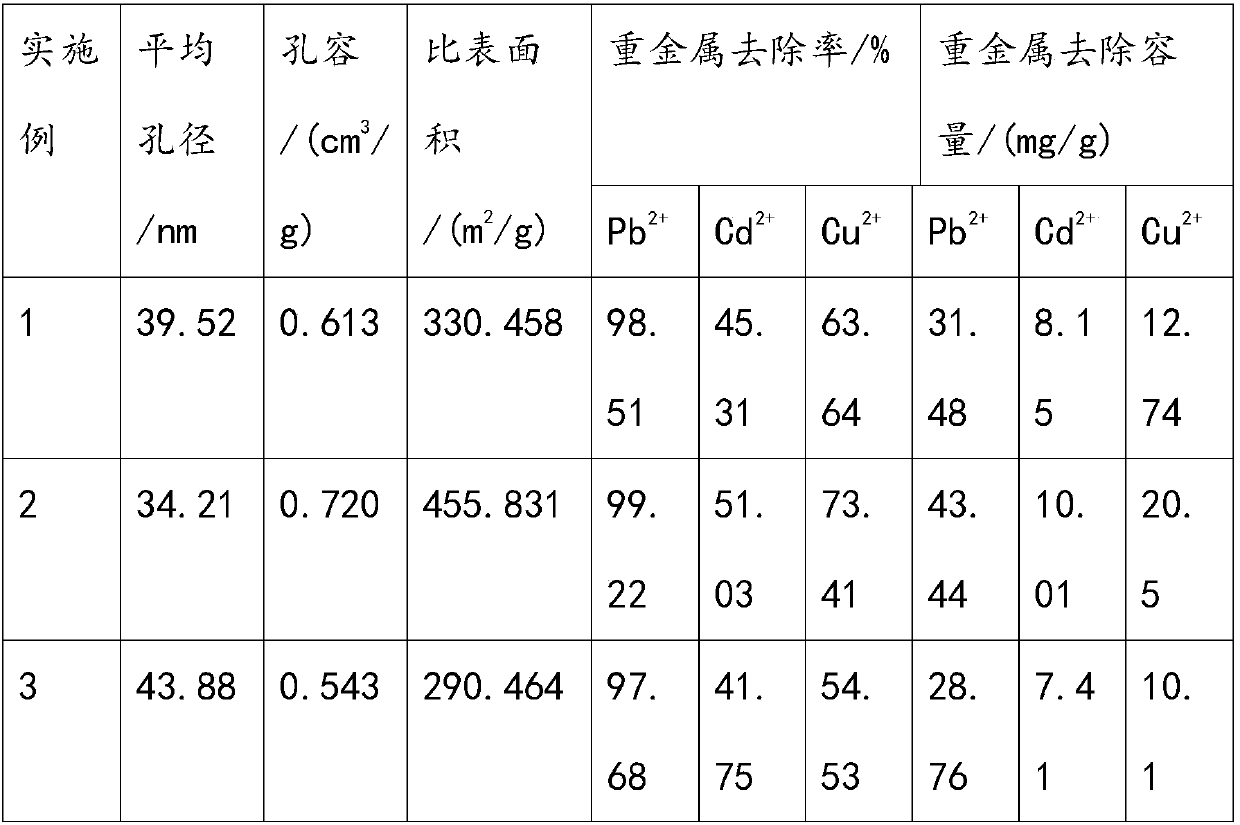

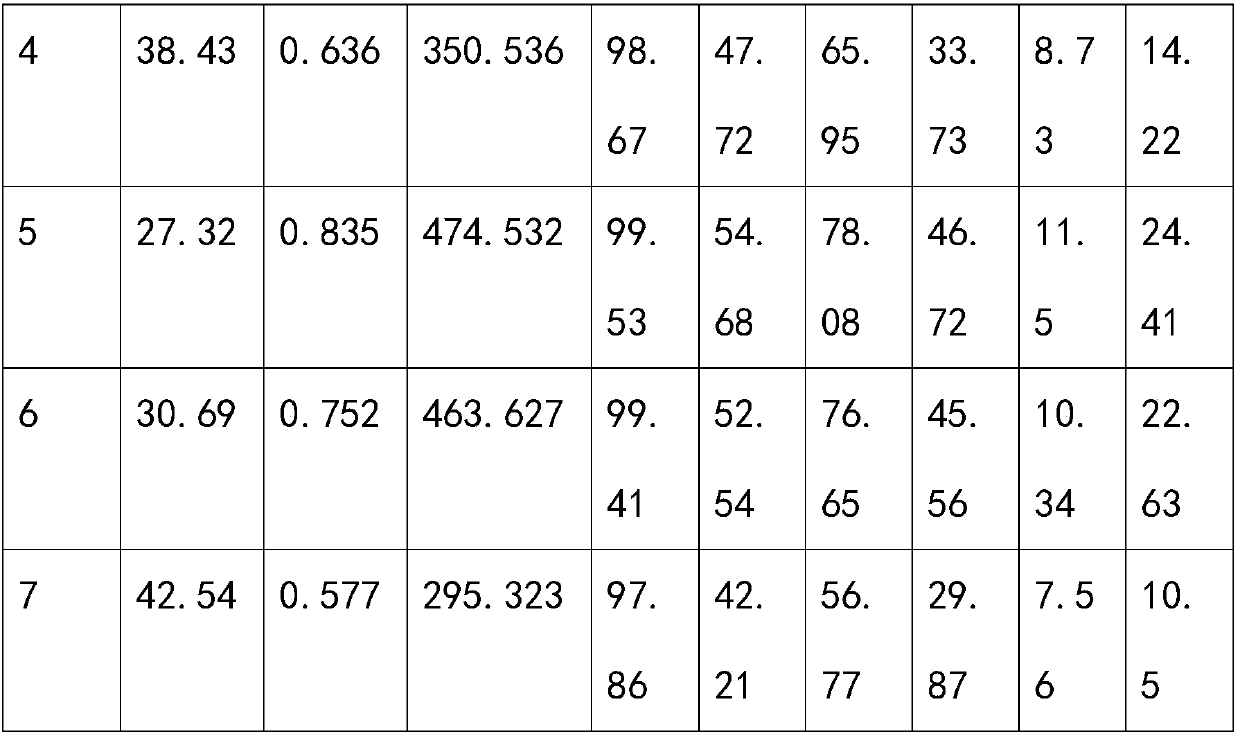

Embodiment 1

[0025] A preparation method of an anglerfish bone biochar capable of adsorbing heavy metals, comprising the following steps:

[0026] (1) Take 100g of sliced and thawed fish bones, add distilled water until submerged, heat on a magnetic heating stirrer at 100°C for 30 minutes, filter and wash with distilled water to remove the attached meat on the fish bones. Crush the fish bones with a pulverizer and pass through a 20-mesh sieve.

[0027] (2) Get 20g of fishbone meal and disperse it in 4mol / L of ZnCl 2 In the solution, in the autoclave at 150°C for 6h, then heated to 250°C for 18h. Cool naturally after the reaction, vacuum filter, and dry at 80°C for 12 hours.

[0028] (3) The dried fishbone meal is placed in a tubular resistance furnace, and nitrogen gas with a flow rate of 100mL / min is introduced into the furnace to maintain an oxygen-deficient environment in the furnace; the heating rate is controlled by the program at 3°C / min, and the temperature is continuously raise...

Embodiment 2

[0031] A preparation method of an anglerfish bone biochar capable of adsorbing heavy metals, comprising the following steps:

[0032] (1) Take 150g of sliced and thawed fish bones, add distilled water until submerged, heat on a magnetic heating stirrer at 100°C for 30 minutes, filter and wash with distilled water to remove the attached meat on the fish bones. Crush the fish bones with a pulverizer and pass through a 20-mesh sieve.

[0033] (2) Get 30g of fishbone meal and disperse it in 6mol / L of ZnCl 2 In the solution, in an autoclave at 160°C for 4h, then raise the temperature to 220°C for 20h. Cool naturally after the reaction, vacuum filter, and dry at 80°C for 12 hours.

[0034] (3) The dried fishbone meal is placed in a tubular resistance furnace, and nitrogen gas with a flow rate of 100mL / min is introduced into the furnace to maintain an oxygen-deficient environment in the furnace; the heating rate is controlled by the program at 3°C / min, and the temperature is cont...

Embodiment 3

[0037] A preparation method of an anglerfish bone biochar capable of adsorbing heavy metals, comprising the following steps:

[0038] (1) Take 200g of sliced and thawed fish bones, add distilled water until submerged, heat on a magnetic heating stirrer at 100°C for 30 minutes, filter and wash with distilled water to remove the attached meat on the fish bones. Crush the fish bones with a pulverizer and pass through a 20-mesh sieve.

[0039] (2) Get 30g of fishbone meal and disperse it in 8mol / L of ZnCl 2 In the solution, in the autoclave at 180°C for 2h, then heated to 200°C for 22h. Cool naturally after the reaction, vacuum filter, and dry at 80°C for 12 hours.

[0040] (3) The dried fishbone meal is placed in a tubular resistance furnace, and nitrogen gas with a flow rate of 100mL / min is introduced into the furnace to maintain an oxygen-deficient environment in the furnace; the heating rate is controlled by the program at 3°C / min, and the temperature is continuously raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com