Machining method for inner shell of motor of new energy vehicle

A technology for a new energy vehicle and a processing method, which is applied to the processing field of the inner casing of a new energy vehicle motor, can solve the problems of easily deformed workpiece quality, instability, and concentricity exceeding poor, so as to solve the problem of unstable quality and save production costs. , the effect of stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

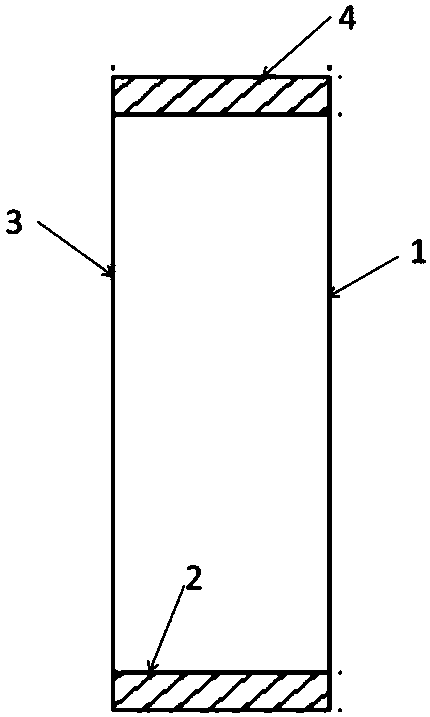

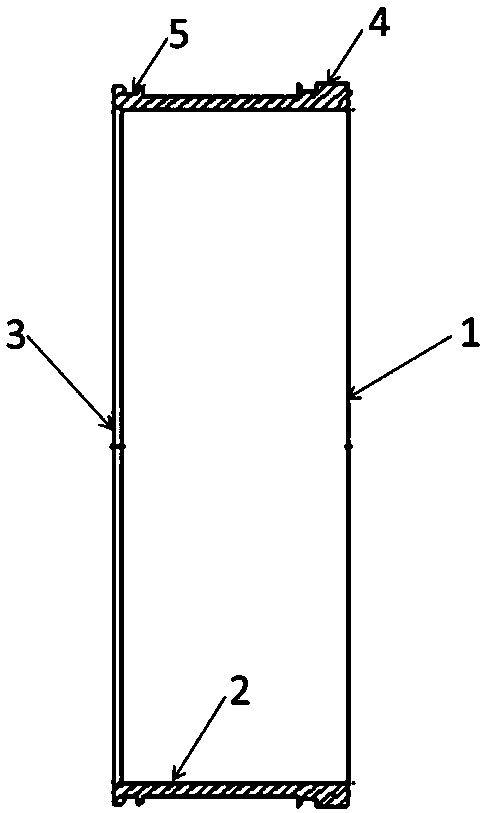

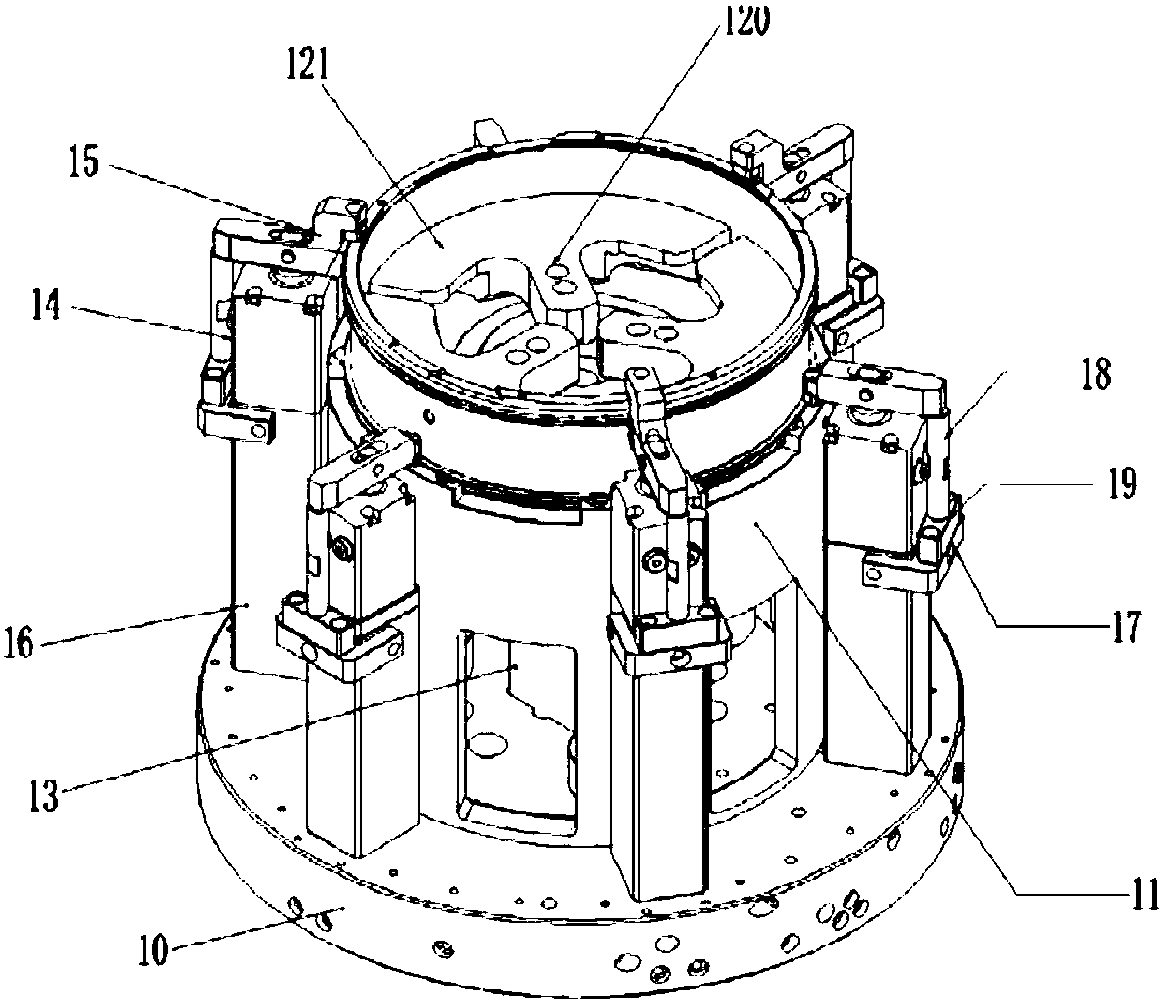

[0036] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

[0037] Please refer to Figure 1 to Figure 4 . The invention proposes a processing method for the inner casing of a new energy motor. During the processing, the machine tool used is equipped with a water temperature cooler, which solves the problem of unstable product quality caused by changes in temperature and cutting fluid temperature. In this embodiment, the specification of the metal pipe raw material is φ320mm*φ283mm, and the material is 6063-T6 hot-extruded aluminum alloy pipe. The tensile strength of the material is greater than or equal to 205MPa, the yield strength is greater than or equal to 170MPa, and the elongation is greater than or equal to 9%.

[0038] The processing technology of the inner casing of the motor specifically includes the following steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com