Permeable asphalt admixture, permeable asphalt and permeable asphalt pavement

A permeable asphalt and admixture technology, applied in the field of permeable asphalt admixture, permeable asphalt and permeable asphalt pavement, can solve the problems of easy blockage of gaps, difficult construction, low strength, etc., achieve fast water permeability, excellent sound absorption and noise reduction effect, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

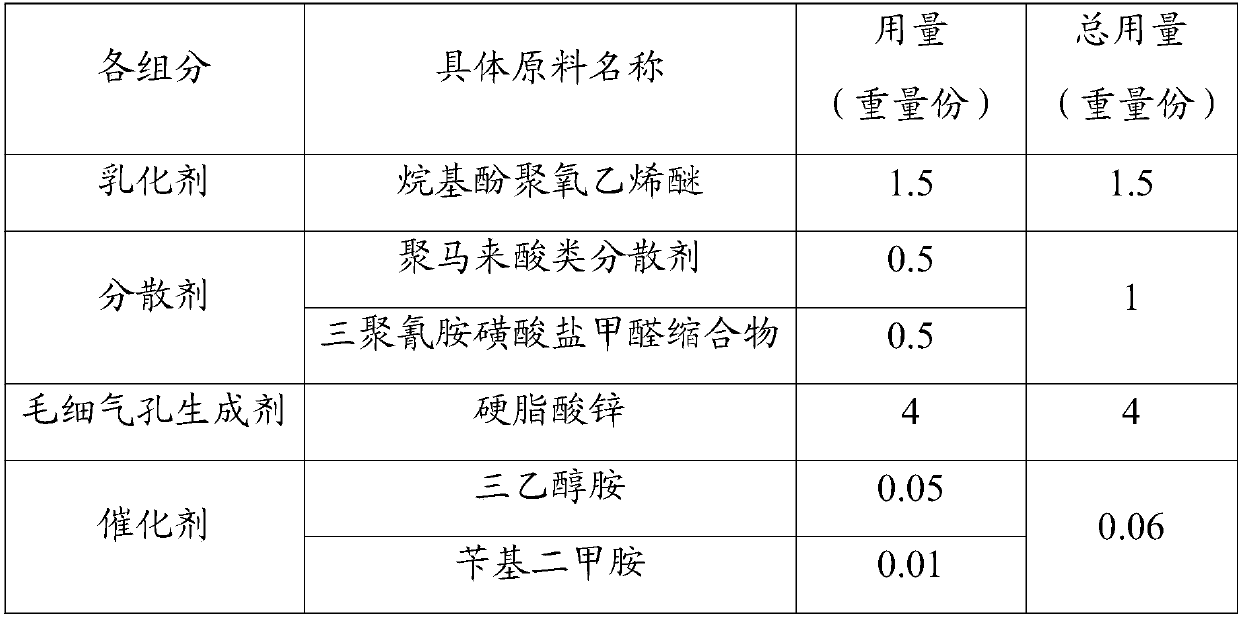

[0023] The raw materials used to prepare the water-permeable asphalt admixture of this embodiment include the following components in parts by weight: 1.5 parts of emulsifier, 1 part of dispersant, 4 parts of capillary pore generator and 0.06 part of catalyst. Wherein, the HLB value of the emulsifier is 8-18, and the emulsifier is an alkylphenol polyoxyethylene ether; the dispersant includes a polycarboxylic acid type dispersant and a pyrimidine type dispersant. The agent adopts polymaleic acid type dispersant, and the pyrimidine type dispersant adopts melamine sulfonate formaldehyde condensate; the capillary pore forming agent is zinc stearate. The components and specific proportions of the raw materials used in the preparation of the above-mentioned permeable asphalt admixture are shown in Table 1.

[0024] Table 1

[0025]

[0026] The preparation method of the water-permeable asphalt admixture of the present embodiment includes: adding the weighed emulsifier, dispersan...

Embodiment 2

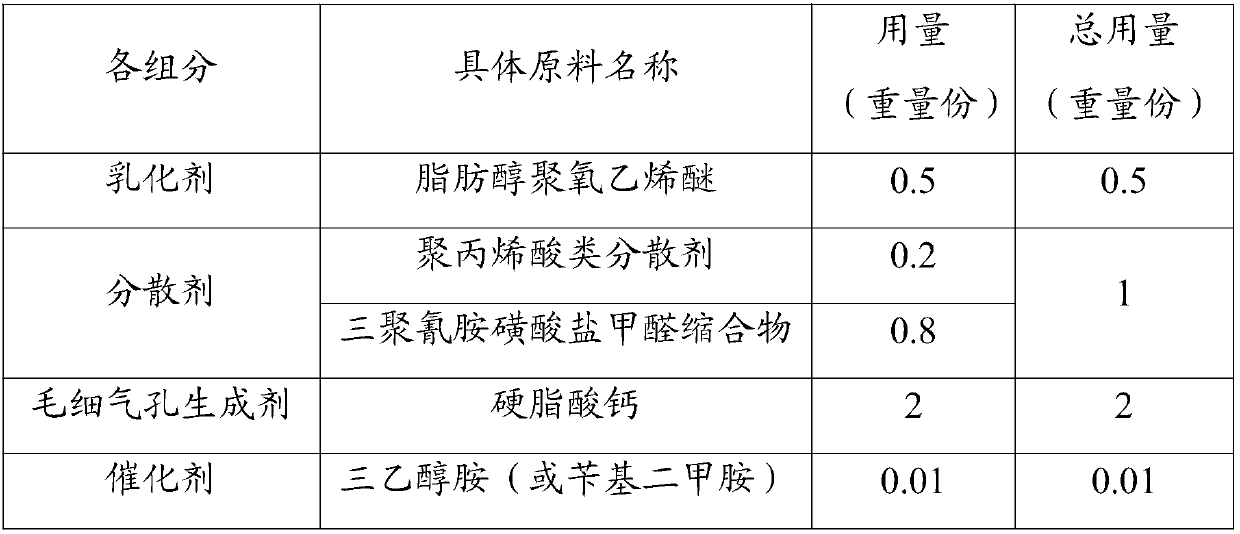

[0030] This example is similar to Example 1, wherein the components and specific proportions of the raw materials used for preparing the water-permeable asphalt admixture are shown in Table 2.

[0031] Table 2

[0032]

[0033] The preparation method of the water-permeable asphalt admixture of the present embodiment includes: adding the weighed emulsifier, dispersant, capillary pore forming agent and catalyst into the reaction kettle, polymerizing for 5 hours under the environment of 40 ° C, and then cooling to room temperature, That is, the permeable asphalt admixture is obtained.

[0034] The above-mentioned permeable asphalt admixture is added to the asphalt according to 5% by weight of the asphalt, and the mixture is stirred and dispersed evenly, that is, the permeable asphalt is prepared.

[0035] In addition to the above, this embodiment also provides a permeable asphalt pavement, which contains the above-mentioned permeable asphalt admixture.

Embodiment 3

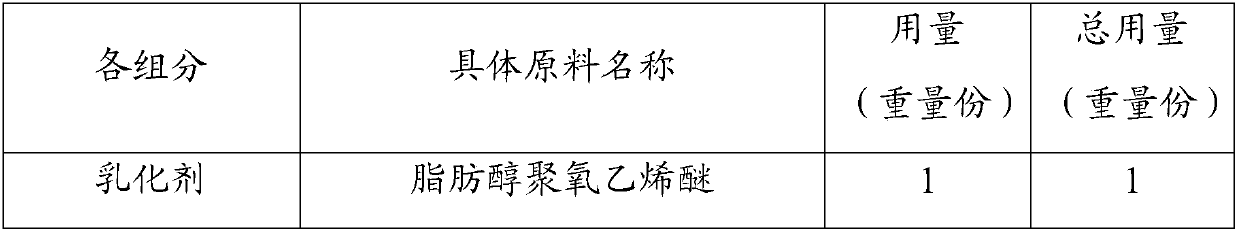

[0037] This example is similar to Example 1, wherein the components and specific proportions of the raw materials used in the preparation of the permeable asphalt admixture are shown in Table 3.

[0038] table 3

[0039]

[0040]

[0041] The preparation method of the water-permeable asphalt admixture of the present embodiment includes: adding the weighed emulsifier, dispersant, capillary pore forming agent, and catalyst into the reaction kettle, polymerizing for 3 hours under the environment of 50 ° C, and then cooling to room temperature, That is, the permeable asphalt admixture is obtained.

[0042] The above-mentioned permeable asphalt admixture is added to the asphalt according to 6.56% of the asphalt weight, and the mixture is stirred and dispersed evenly, that is, the permeable asphalt is prepared.

[0043] In addition to the above, this embodiment also provides a permeable asphalt pavement, which contains the above-mentioned permeable asphalt admixture.

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com