Doublet closed pore structure foam polymer composite material and preparation method thereof

A technology of foamed polymers and composite materials, applied in the field of porous polymer materials, can solve the problems of mechanical properties that need to be improved, extrusion pressure is difficult to control accurately, and the mechanical strength of foamed materials is low, so as to overcome the size and density of cells Difficult to regulate, increase the controllability of the method, and the effect of easy individual control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

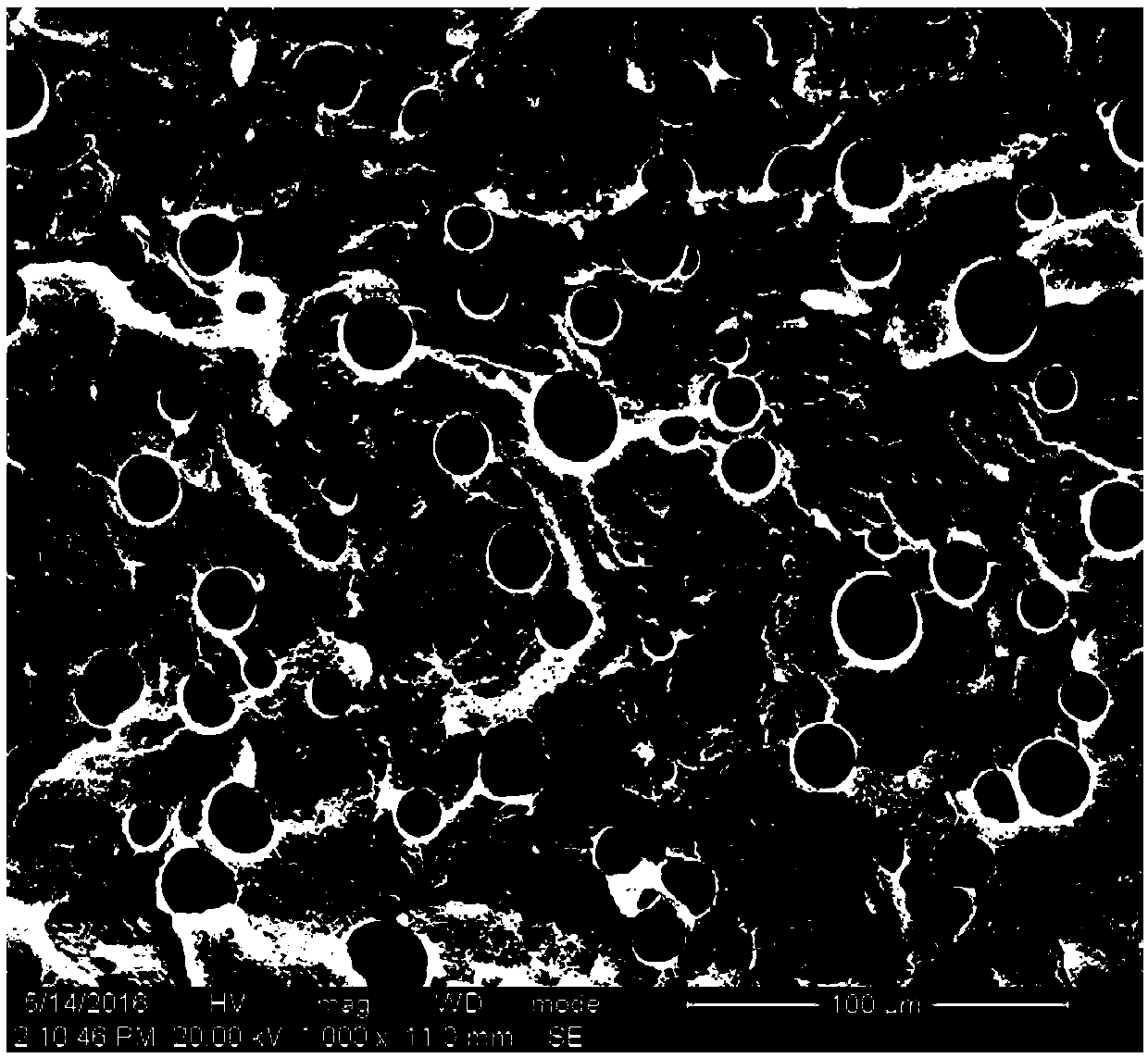

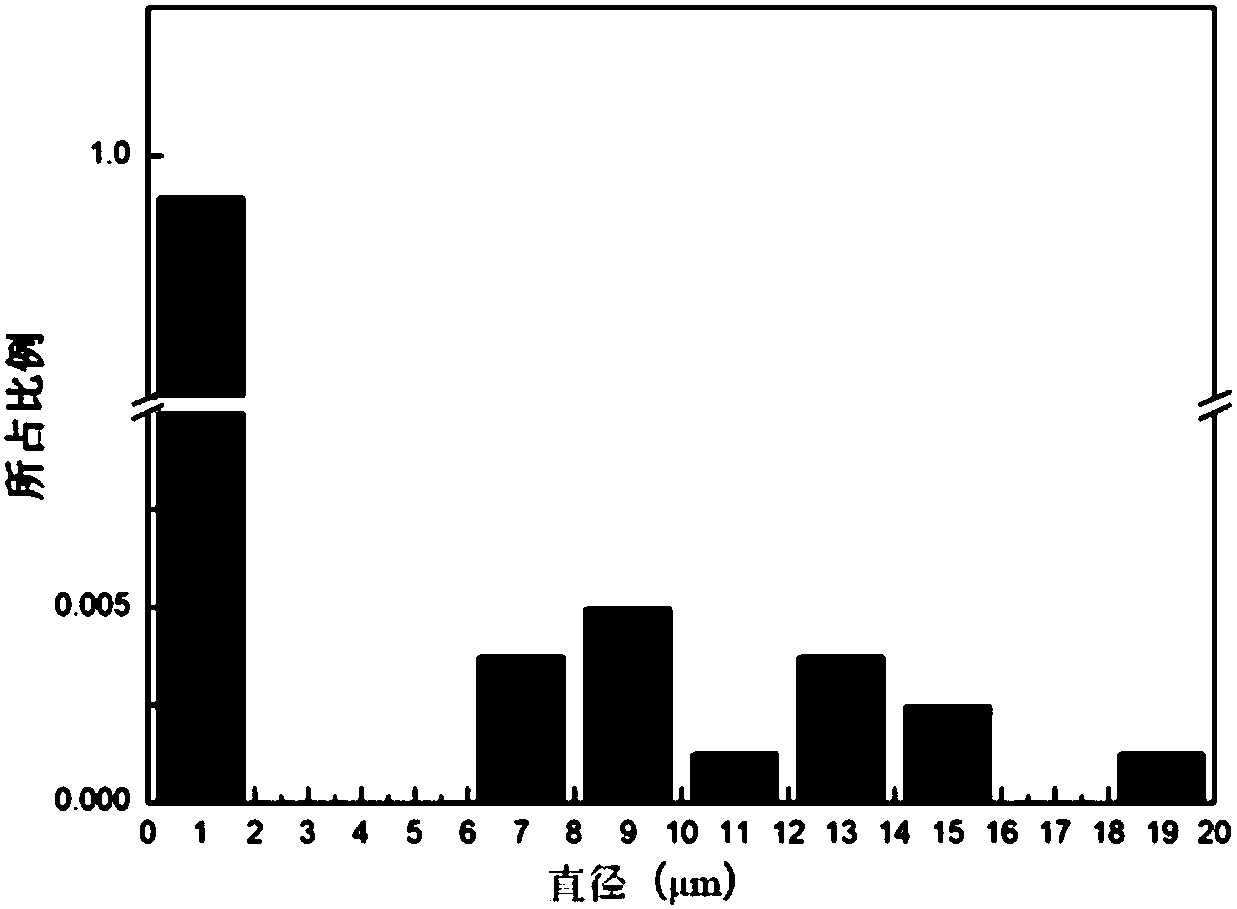

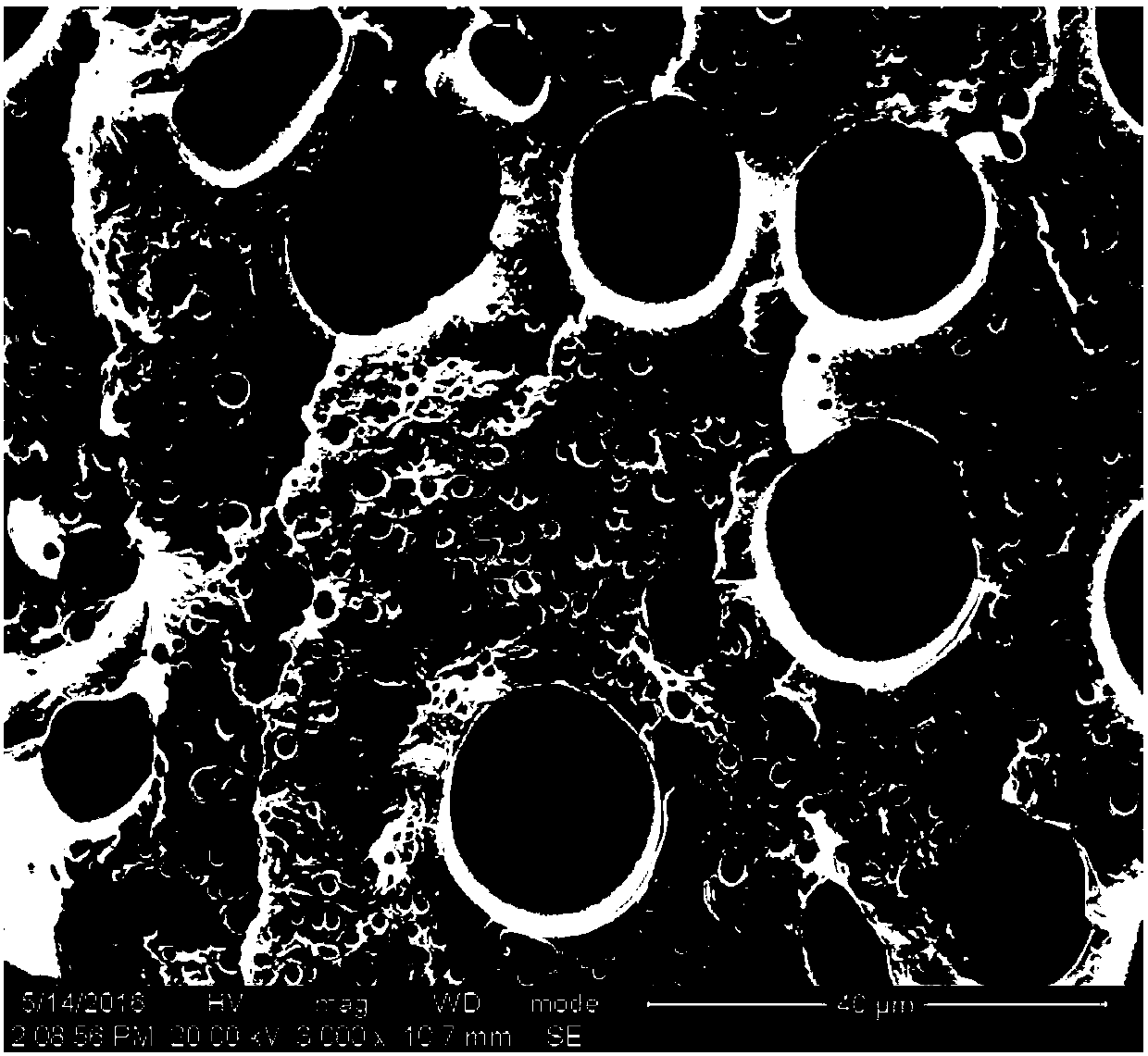

[0037] In this example, the foamed polystyrene composite material with bimodal closed-cell structure is prepared, and the steps are as follows:

[0038] (1) Using polystyrene (PS) as the matrix material and fullerene (FE) as the inorganic nano-filler, the solution blending method is used to uniformly disperse FE in PS, and the operation is as follows:

[0039] Add 10g PS to 100mL N,N-dimethylformamide (DMF) at 70°C and stir until PS is completely dissolved to form a PS solution. Add 50mg FE to 50mL DMF, and sonicate for 8h under 200W ultrasonic conditions to make FE Uniformly disperse in DMF to form FE dispersion, and then ultrasonicate the obtained PS solution and FE dispersion for 8 hours under 200W ultrasonic conditions to mix the PS solution and FE dispersion evenly to obtain a composite material dispersion, and control the temperature during the ultrasonic process not to exceed 60°C.

[0040] Using the anti-solvent method, slowly drop the composite material dispersion in...

Embodiment 2

[0045] In this example, the foamed polystyrene composite material with bimodal closed-cell structure is prepared, and the steps are as follows:

[0046] (1) Using PS as the matrix material and multi-walled carbon nanotubes (MWNTs) as the inorganic nanofiller, the MWNTs were uniformly dispersed in the PS by the solution blending method, and the operation was as follows:

[0047] Add 10g PS into 100mL DMF at 70°C and stir until PS is completely dissolved to form a PS solution, add 100mg MWNTs into 50mL DMF, and sonicate under 500W ultrasonic conditions for 2h, so that MWNTs are uniformly dispersed in DMF to form a MWNTs dispersion, and then The obtained PS solution and MWNTs dispersion were sonicated under 500W ultrasonic conditions for 8 hours to mix the PS solution and MWNTs dispersion uniformly to obtain a composite material dispersion, and the temperature during the sonication process was controlled not to exceed 60°C.

[0048] Using the anti-solvent method, slowly drop the ...

Embodiment 3

[0053] In this example, the foamed polystyrene composite material with bimodal closed-cell structure is prepared, and the steps are as follows:

[0054] (1) With PS as the matrix material and FE as the inorganic nano-filler, FE is uniformly dispersed in PS by the solution blending method, and the operation is as follows:

[0055] Add 10g PS into 100mL DMF at 70°C and stir until PS is completely dissolved to form a PS solution, add 5mg FE into 50mL DMF, and sonicate under 200W ultrasonic conditions for 8h, so that FE is uniformly dispersed in DMF to form a FE dispersion, and then The obtained PS solution and FE dispersion were sonicated under 200W ultrasonic conditions for 8 hours to mix the PS solution and FE dispersion uniformly to obtain a composite material dispersion, and the temperature during the ultrasonic process was controlled not to exceed 60°C.

[0056] Using the anti-solvent method, slowly drop the composite material dispersion into 1.5L ethanol to precipitate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com