Agreement structure for friction nano generator-used friction layer material surface roughness and manufacturing method thereof

A nanogenerator and surface roughening technology, applied in the direction of triboelectric generators, can solve the problems of cumbersome process, high preparation cost, long time consumption, etc., and achieve the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

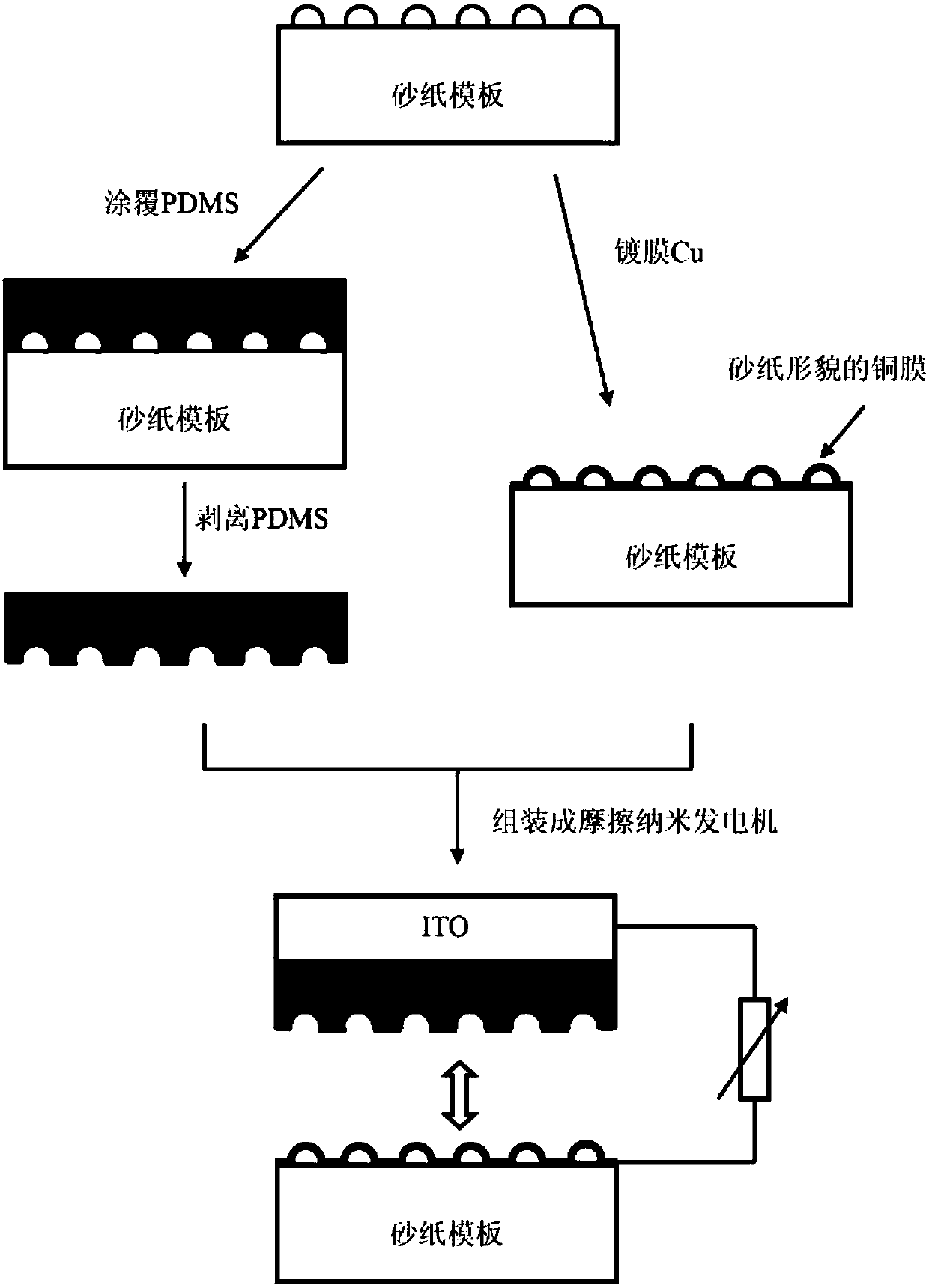

[0047] refer to figure 1 A schematic diagram of the preparation process, a method for preparing a friction layer material with a roughened surface for a friction nanogenerator, including:

[0048] step 1):

[0049] Step (1a), first cut the 10,000-mesh sandpaper into 3cm×3cm, then ultrasonically clean the sandpaper with alcohol, and finally dry it for later use;

[0050] Step (1b), first prepare the PDMS solution: first weigh the PDMS preparation raw material prepolymer A and crosslinking agent B according to the mass ratio of 10:1, and then put them on a magnetic stirrer and stir for 15-60 minutes to make the two components fully well mixed;

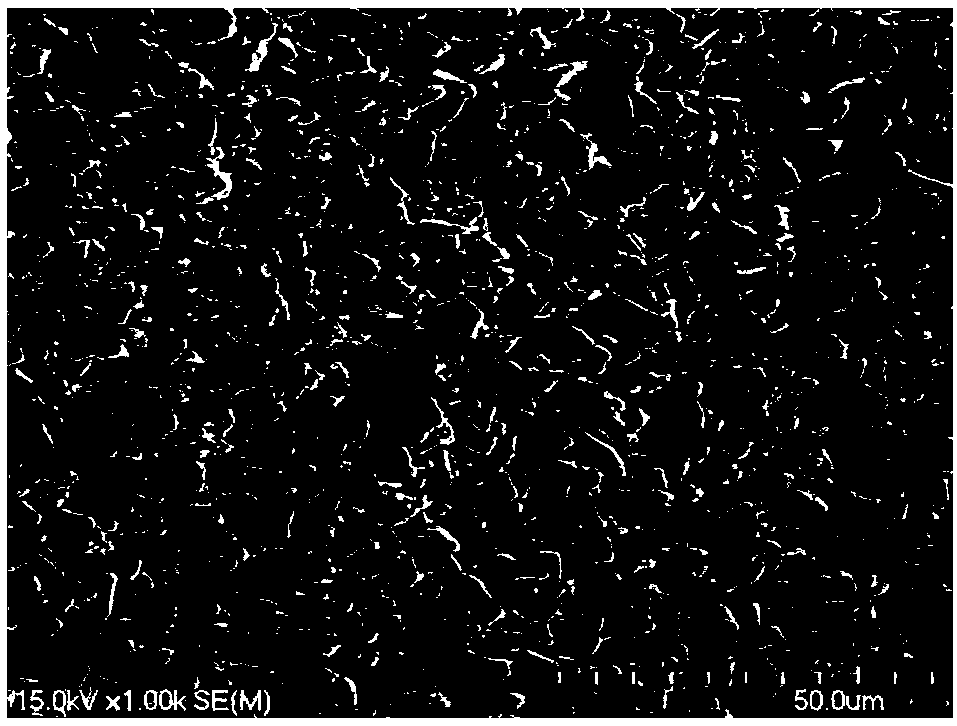

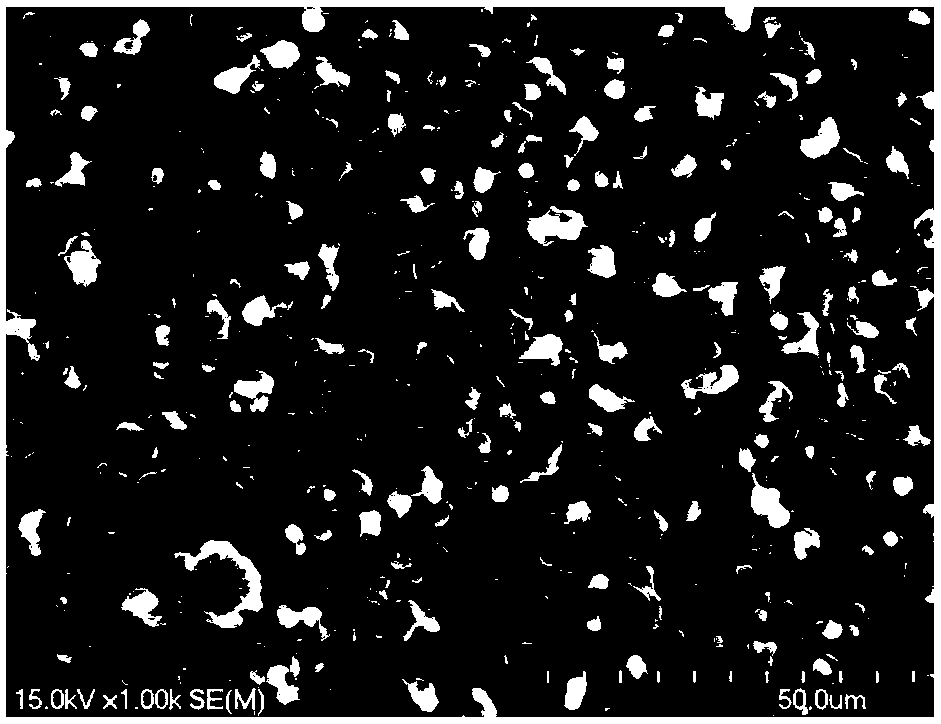

[0051] Step (1c), put the uniformly mixed PDMS solution into a vacuum degassing device to remove air bubbles in the mixed solution. Then use the spin-coating method to spin-coat the PDMS solution on the spare sandpaper, then put the sandpaper spin-coated with PDMS on a heating table at 80-250°C, heat it for 15-60min, take it off and c...

Embodiment 2

[0060] Different from Example 1, only the sandpaper mesh number of step (1a) is changed to be 12000 mesh, and other steps remain unchanged. Since the larger the mesh number of the sandpaper is, the smaller the structural size is, and the output performance of the triboelectric nanogenerator is better.

Embodiment 3

[0062] The difference from Example 1 is that the sandpaper template in step (1a) is changed to a photolithographic silicon template, and other steps remain unchanged. As the feature size of the photolithographic template pattern is reduced, the device performance is better. (Whether it is a fine silicon template or a simple sandpaper template, as long as the size of the surface is smaller, the performance will be better)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com