Feed production system and process for pregnant sow

A technology for pregnant sows and production systems, which is applied in the field of feed production systems and processes for pregnant sows, can solve problems such as inability to guarantee the dryness of raw materials, excessive magnesium sulfate, etc., so as to improve the survival rate of embryos, shorten the labor process, and improve the allocation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

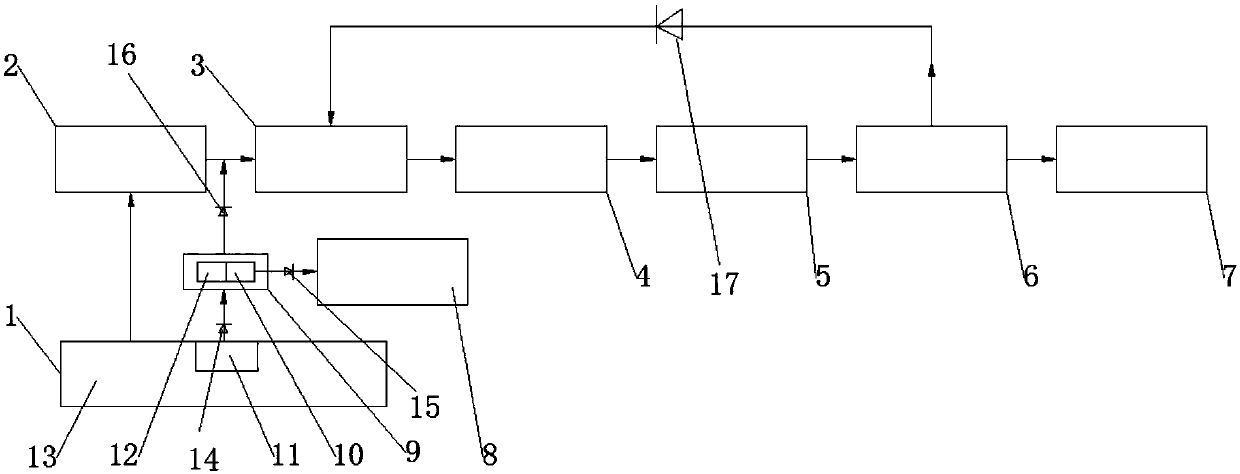

[0033] A feed production system for pregnant sows such as figure 1 As shown, it consists of sequentially connected batching bin 2, first mixing mechanism 3, second mixing mechanism 4, crushing mechanism 5, tempering mechanism 6 and forming mechanism 7, and also includes storage bin 1, storage bin 1 It consists of the first sub-bin 11 and the second sub-bin 13 isolated from the first sub-bin 11. The first sub-bin 11 is used to store magnesium sulfate powder, the second sub-bin 13 is used to store the base material, and the first sub-bin 11 The outlet of the magnesium sulfate is connected with a magnesium sulfate weighing mechanism 9, and the magnesium sulfate weighing mechanism 9 is provided with a magnesium sulfate feeding outlet and a magnesium sulfate recovery outlet, and the magnesium sulfate feeding outlet is connected with the inlet of the first mixing mechanism 3, and the magnesium sulfate recovery outlet is connected with Magnesium sulfate recovery mechanism 8, the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com