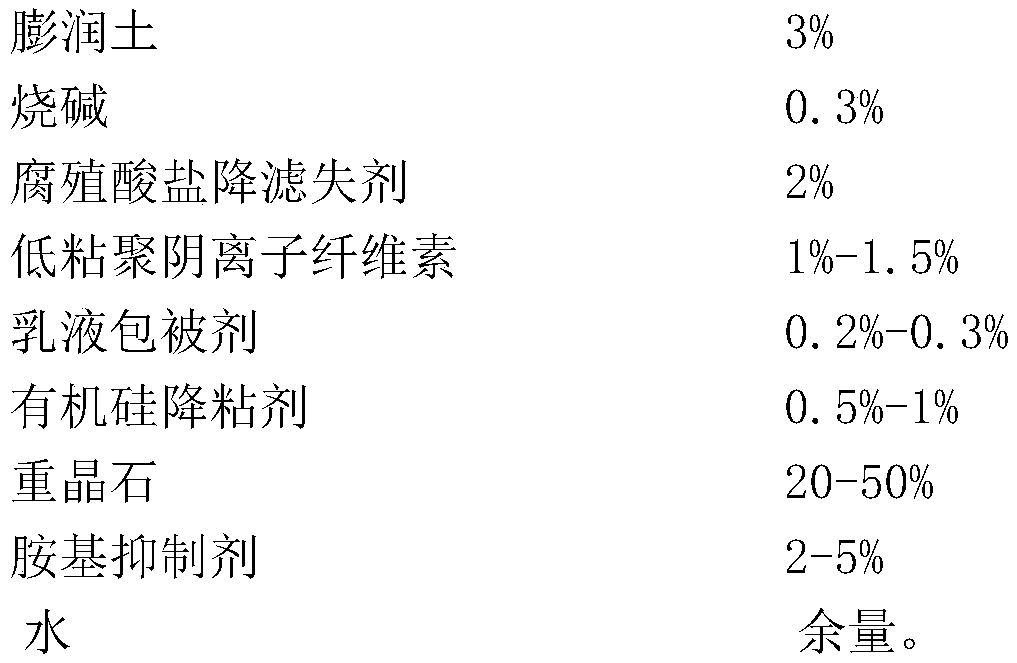

Amine-based inhibitor for water-based drilling fluid, water-based drilling fluid system and preparation method

A technology of water-based drilling fluid and inhibitor, which is applied in the field of water-based drilling fluid system and amine-based inhibitor for water-based drilling fluid, which can solve the problem of insufficient stability to meet construction needs, weak inhibition performance, and water-based drilling fluid flow. Issues such as greater impact of degeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the first embodiment of the present application, a method for preparing an amine-based inhibitor for water-based drilling fluid is provided, comprising the following steps:

[0036] Mix polyol amines with chloropropane compounds to react to obtain polyalcohol acid propylammonium chloride;

[0037] Wherein, the polyol amine includes triethanolamine and optional ethanolamine and / or diethanolamine, and the chloropropane compound is selected from epichlorohydrin, methyl epichlorohydrin, trichloropropane, 2-methyl- One or more of 2-chloropropane and 2-methyl-1-chloropropane.

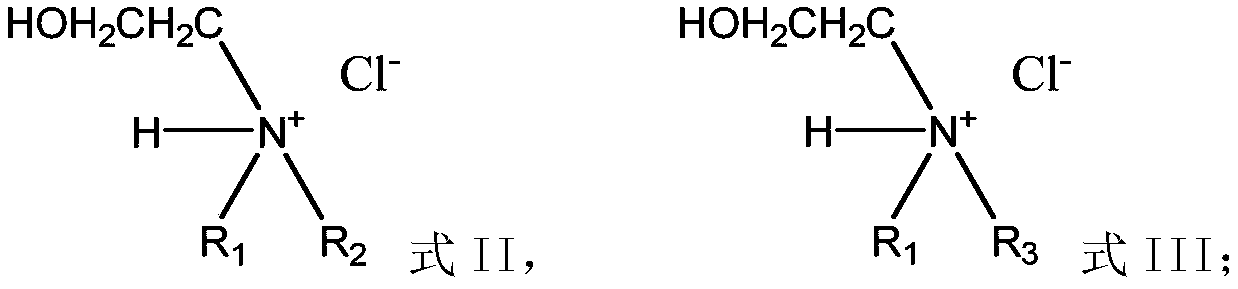

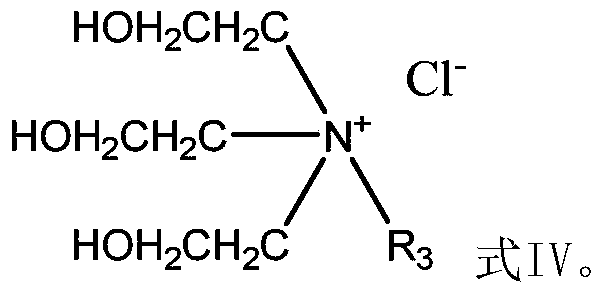

[0038] In the above preparation method, when the polyol amine includes triethanolamine, a nucleophilic substitution reaction occurs between triethanolamine and chloropropane compounds to obtain compound 1 shown in formula I, as shown in reaction formula 1:

[0039]

[0040] Wherein, as chloropropane compound comprises epichlorohydrin, group R2 is

[0041] Such as chloropropane compounds inclu...

Embodiment 1

[0091] (1) Add 100g of water to a 500mL three-necked flask;

[0092] (2) In the there-necked flask, add 100g polyol amine while stirring, and the polyol amine is triethanolamine;

[0093] (3) Add 100g of chloropropane compound dropwise in a three-necked flask, and the chloropropane compound is methyl epichlorohydrin;

[0094] (4) After the dropwise addition, the temperature was raised to 70° C., and the reaction was kept for 4 hours to obtain the amine-based inhibitor 1.

Embodiment 2

[0096] (1) Add 100g of water to a 500mL three-necked flask;

[0097] (2) In the three-necked flask, add 127.5 g of polyol amine while stirring, the polyol amine is a mixture of triethanolamine and ethanolamine, wherein the weight ratio of triethanolamine and ethanolamine is 1:10;

[0098] (3) Add 90g of chloropropane compounds dropwise in a three-necked flask, and the chloropropane compounds are trichloropropane;

[0099] (4) After the dropwise addition, the temperature was raised to 70° C., and the mixture was kept for 4 hours to obtain the amine-based inhibitor 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com