Bamboo fiber/polylactic acid composite material and preparation method thereof

A composite material and bamboo fiber technology, which is applied in the field of bamboo fiber/polylactic acid composite material and its preparation, can solve the problems of large waste gas pollution, low reaction efficiency, and high energy consumption, and achieve the effect of low equipment requirements and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

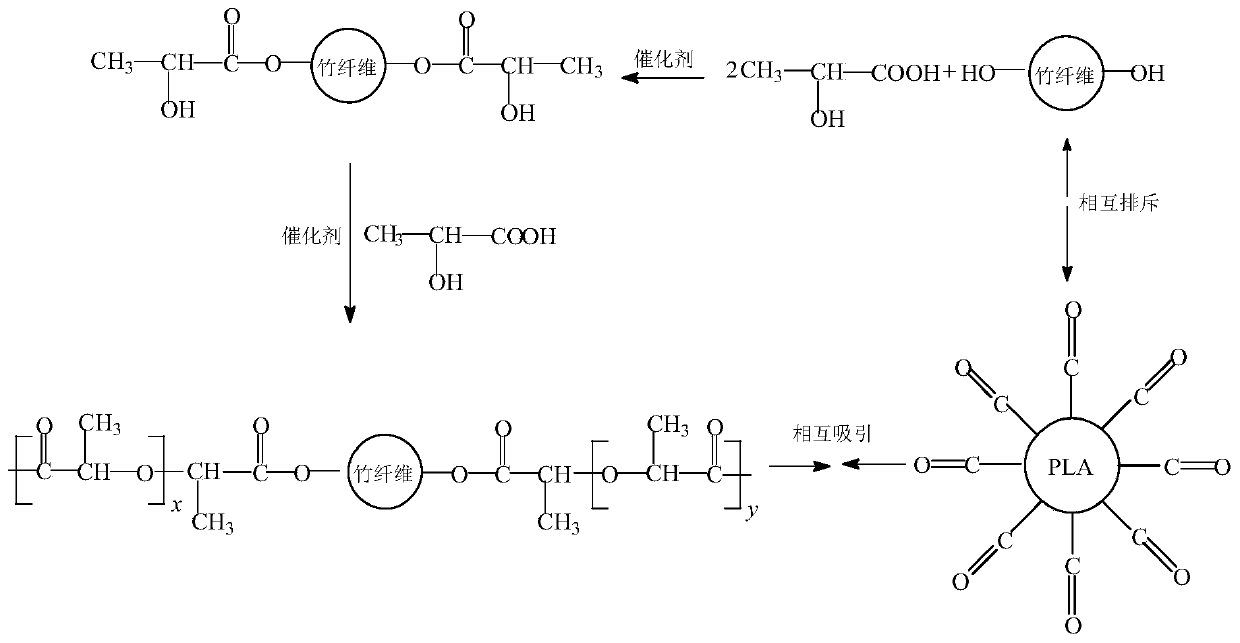

Method used

Image

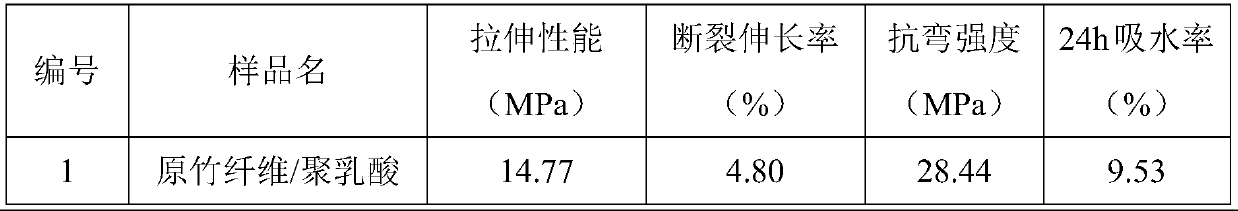

Examples

Embodiment 1

[0030] A kind of modified bamboo fiber / polylactic acid composite material of the present invention is prepared by the following method:

[0031] (1) Disperse 0.1 parts by weight of catalyst (the catalyst is stannous octoate) in 10 parts by weight of lactic acid monomer to obtain a dispersion. Add 100 parts by weight of bamboo fibers to the dispersion liquid, and stir evenly to obtain a mixture.

[0032] (2) Put the mixture in the step (1) in a hydrothermal reaction kettle, seal it; react at a temperature of 120° C. for 12 hours to obtain lactic acid grafted bamboo fiber.

[0033] (3) Mix 900 parts by weight of polylactic acid resin with the lactic acid grafted bamboo fiber obtained in step (2), add 120 parts by weight of plasticizer (glycerin), and place it in a sealed place at room temperature for 6 hours. A two-roller mixer was used for mixing, the mixing temperature was 150° C., and the mixing time was 10 minutes to obtain a mixed product.

[0034] (4) After the mixed pro...

Embodiment 2

[0041] A kind of modified bamboo fiber / polylactic acid composite material of the present invention is prepared by the following method:

[0042] (1) Disperse 2 parts by weight of the catalyst (the catalyst is stannous octoate) in 100 parts by weight of lactic acid monomer to obtain a dispersion. Add 100 parts by weight of bamboo fibers to the dispersion liquid, and stir evenly to obtain a mixture.

[0043] (2) Put the mixture in the step (1) in a hydrothermal reaction kettle, seal it; react at a temperature of 100°C for 8 hours to obtain lactic acid grafted bamboo fiber.

[0044] (3) 500 parts by weight polylactic acid resin is mixed with the lactic acid grafted bamboo fiber obtained in step (2), add 90 parts by weight of plasticizer (plasticizer comprises 45 parts by weight of citric acid ester and 45 parts by weight of formamide ), sealed at room temperature for 12h. A two-roller mixer was used for mixing, the mixing temperature was 160° C., and the mixing time was 15 minu...

Embodiment 3

[0051] A kind of modified bamboo fiber / polylactic acid composite material of the present invention is prepared by the following method:

[0052] (1) Disperse 4 parts by weight of catalyst (the catalyst is triethylaluminum) in 200 parts by weight of lactic acid monomer to obtain a dispersion. Add 100 parts by weight of bamboo fibers to the dispersion liquid, and stir evenly to obtain a mixture.

[0053] (2) Put the mixture in the step (1) in a hydrothermal reaction kettle, seal it; react at a temperature of 80°C for 3 hours to obtain lactic acid grafted bamboo fiber.

[0054] (3) Mix 100 parts by weight polylactic acid resin with the lactic acid grafted bamboo fiber obtained in step (2), add 18 parts by weight plasticizer (plasticizer comprises 6 parts by weight polyethylene glycol 400, 6 parts by weight Formamide and 6 parts by weight of citric acid ester), sealed at room temperature for 18h. A two-roller mixer was used for mixing, the mixing temperature was 180° C., and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com