Luminescent polyvinyl alcohol material and preparation method thereof

A technology of polyvinyl alcohol and alkyd acid, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem that the luminous color is not adjustable, achieve the effect of overcoming adverse effects, excellent mechanical properties, and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

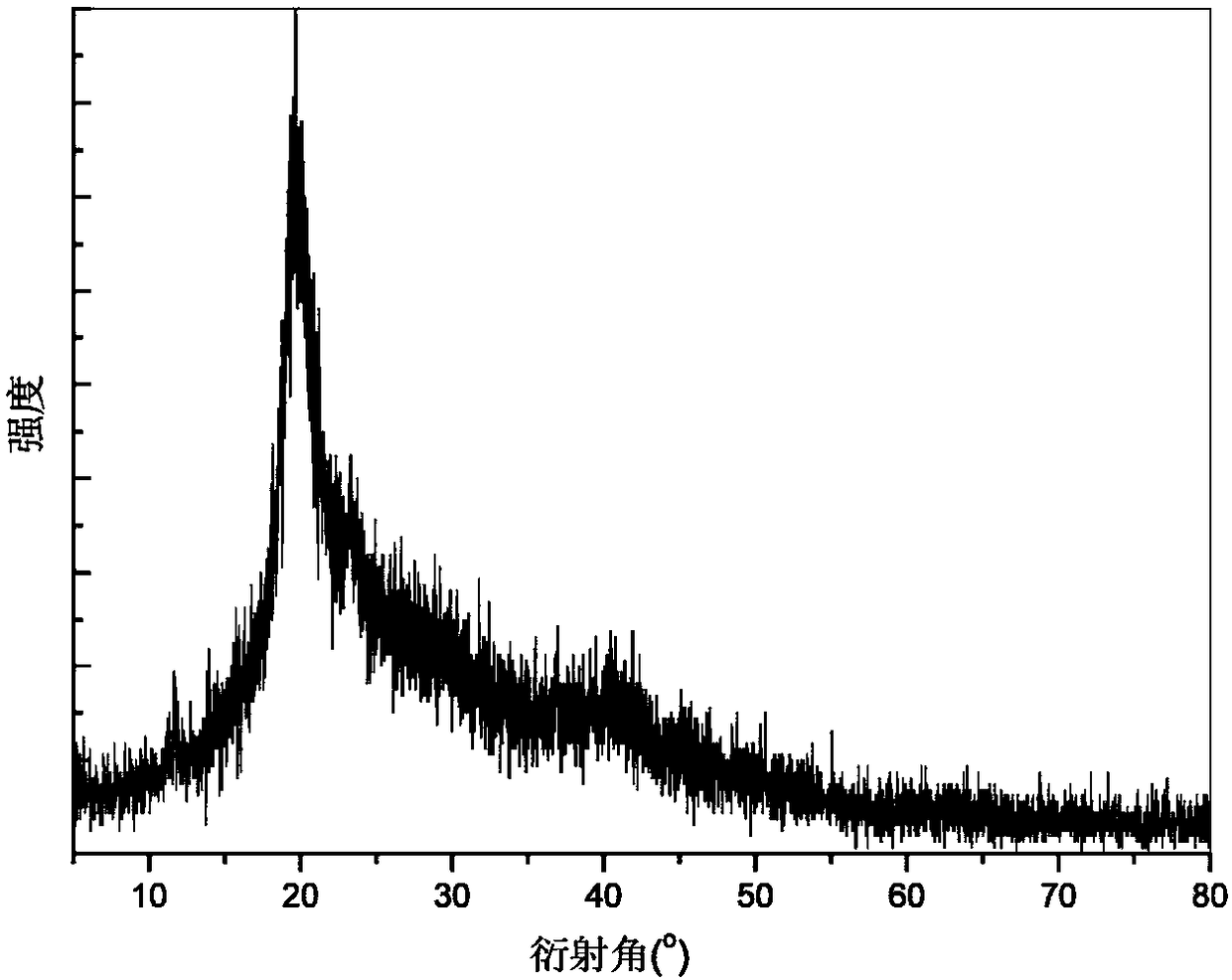

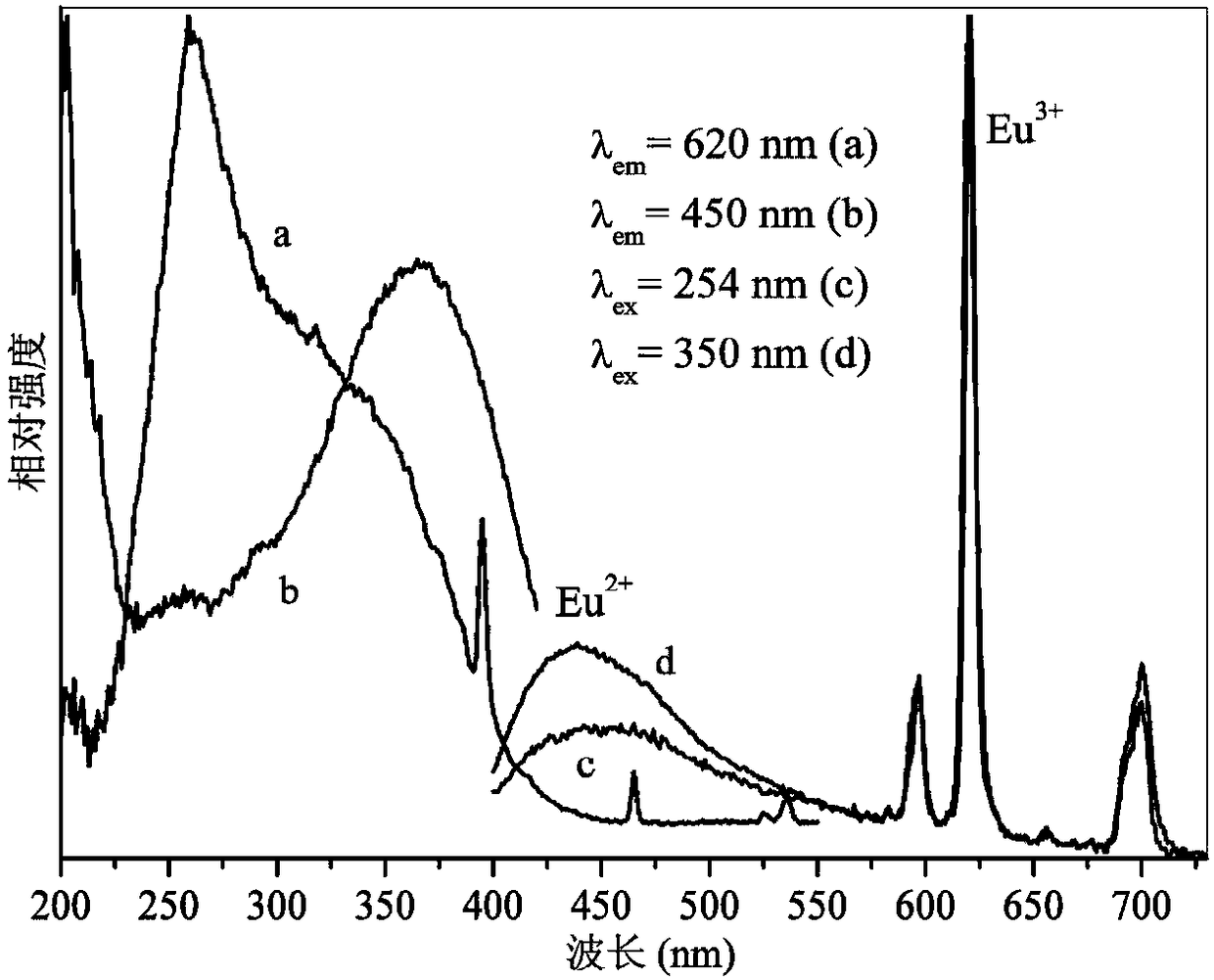

[0022] The preparation method of luminescent polyvinyl alcohol material according to one embodiment of the present invention comprises the following steps: dissolving polyvinyl alcohol, aldehyde acid and europium element ionic compound in a solvent, and adjusting the pH to neutral or alkaline, and then Hydrothermal solvothermal synthesis reaction at 140°C for 0.5-24 hours, after drying, the luminescent polyvinyl alcohol material can be obtained.

[0023] Hydrothermal solvothermal synthesis refers to the synthesis of reactants in water or other solvents under certain temperature and pressure conditions. The reaction is generally carried out in a closed container or autoclave, and the reaction is under subcritical or supercritical conditions. At this time, the reactivity of water or other solvents increases, and the physical and chemical properties of the substance in the solvent also change greatly, which is conducive to the generation of metastable substances with novel structu...

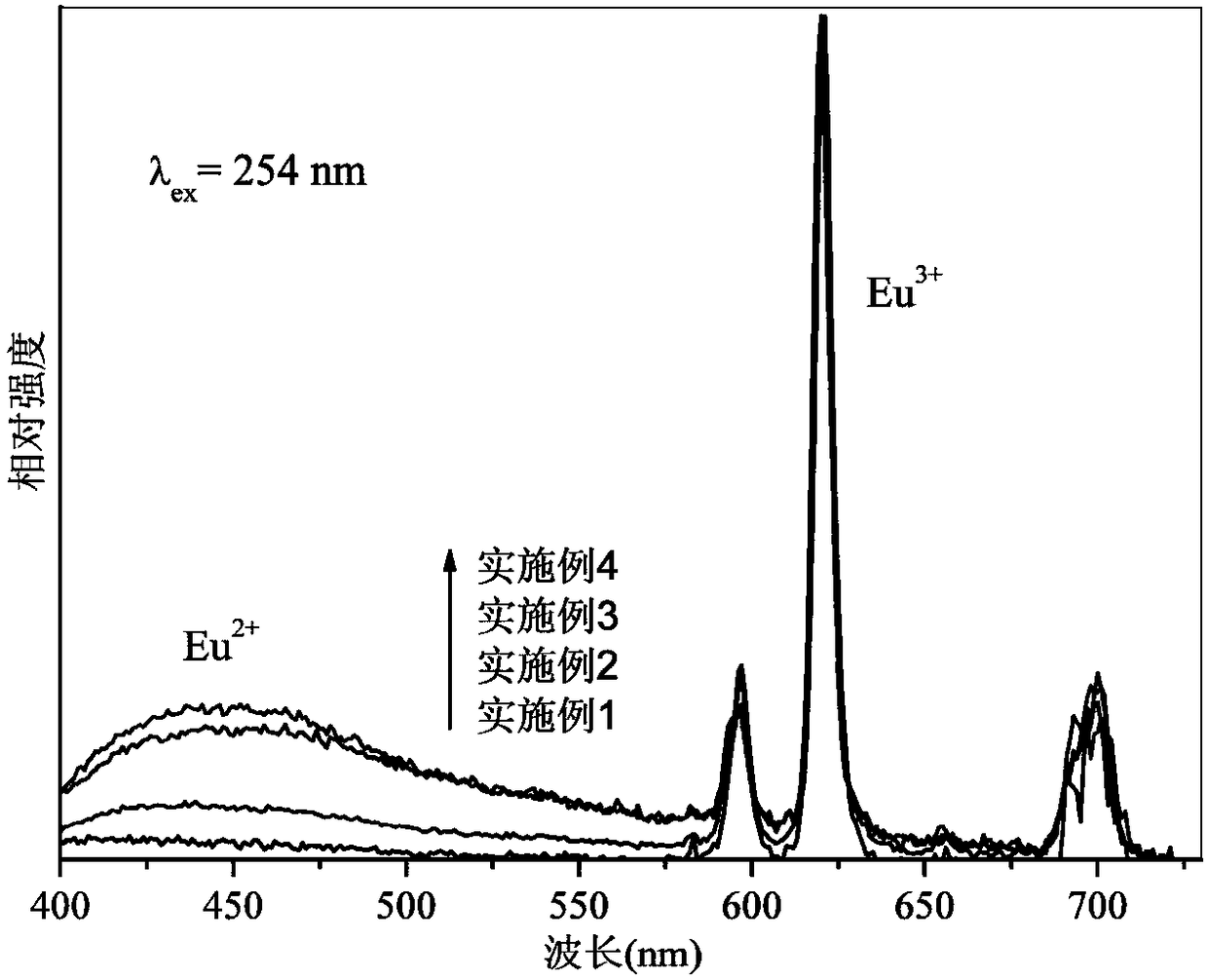

Embodiment 1

[0033] Weigh 3g of polyvinyl alcohol and add it to 17g of water, stir in a water bath at 90°C for 1.5 hours to obtain a polyvinyl alcohol solution with a mass fraction of 15%, and use water as a solvent to prepare Eu(NO 3 ) 3 solution and 5mol / L ammonia water.

[0034] Add 1.008g glyoxylic acid to the prepared polyvinyl alcohol solution, then add 3ml prepared Eu(NO 3 ) 3 The solution and 2.5ml of ammonia water were tested to be pH 7-8, stirred at room temperature for 30 minutes and mixed evenly, then transferred to a hydrothermal reaction kettle with a filling degree of 80%, reacted for 12 hours at 80°C for hydrothermal synthesis, and poured after cooling On a glass sheet, it is cast into a film and dried naturally to obtain a film-like luminescent polyvinyl alcohol material with adjustable luminescence.

Embodiment 2

[0036] Weigh 3g of polyvinyl alcohol and add it to 17g of water, stir in a water bath at 90°C for 1.5 hours to obtain a polyvinyl alcohol solution with a mass fraction of 15%, and use water as a solvent to prepare Eu(NO 3 ) 3 solution and 5mol / L ammonia water.

[0037]Add 1.008g glyoxylic acid to the prepared polyvinyl alcohol solution, then add 3ml prepared Eu(NO 3 ) 3 The pH of the solution and 2.5ml of ammonia water was tested to be 7-8, stirred at room temperature for 30 minutes and mixed evenly, then transferred to a hydrothermal reaction kettle with a filling degree of 80%, reacted for 12 hours at 100°C for hydrothermal synthesis, and poured after cooling On a glass sheet, it is cast into a film and dried naturally to obtain a film-like luminescent polyvinyl alcohol material with adjustable luminescence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com