A kind of cadmium telluride quantum dot-silk protein and hydrotalcite composite luminescent film and preparation method thereof

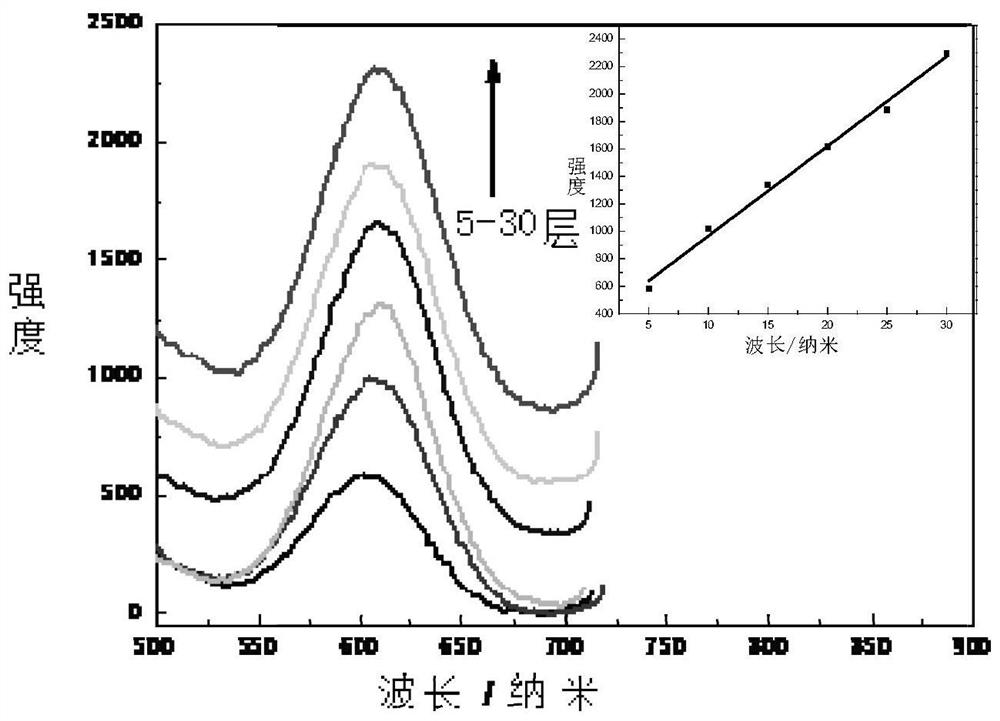

A technology of cadmium telluride quantum dots and silk protein, which is applied in the field of cadmium telluride quantum dots-silk protein and hydrotalcite composite luminescent film and its preparation, can solve the problems that there is no luminescent film, and achieve the improvement of fluorescence intensity and stability , the preparation method is simple, the effect of precise control of film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Cadmium telluride quantum dots-silk protein and hydrotalcite composite luminescent film, the steps are as follows:

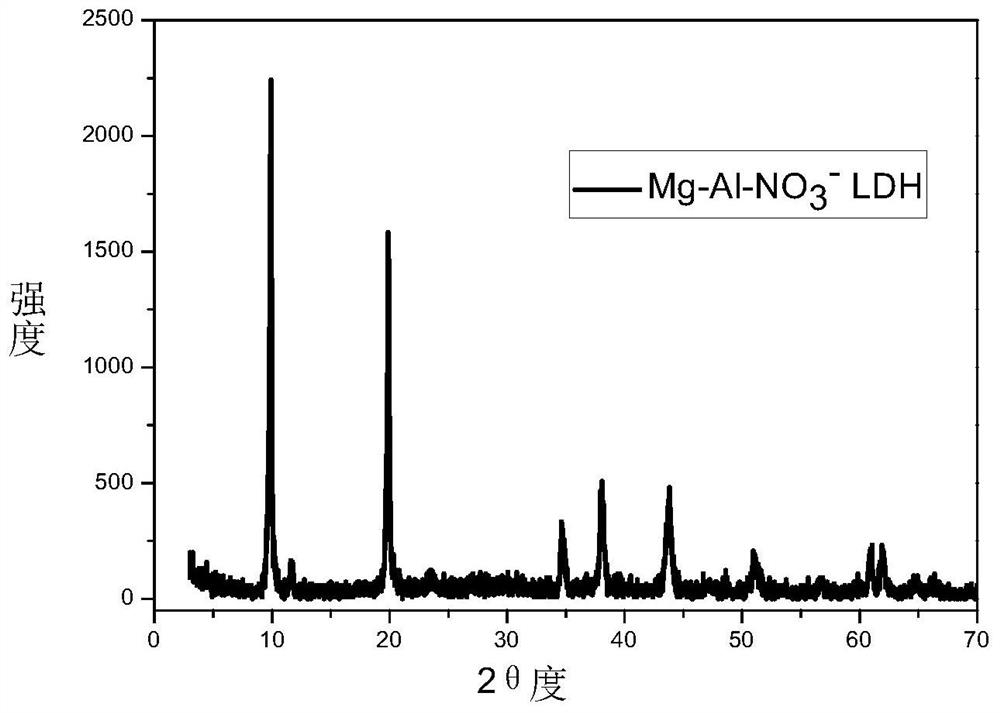

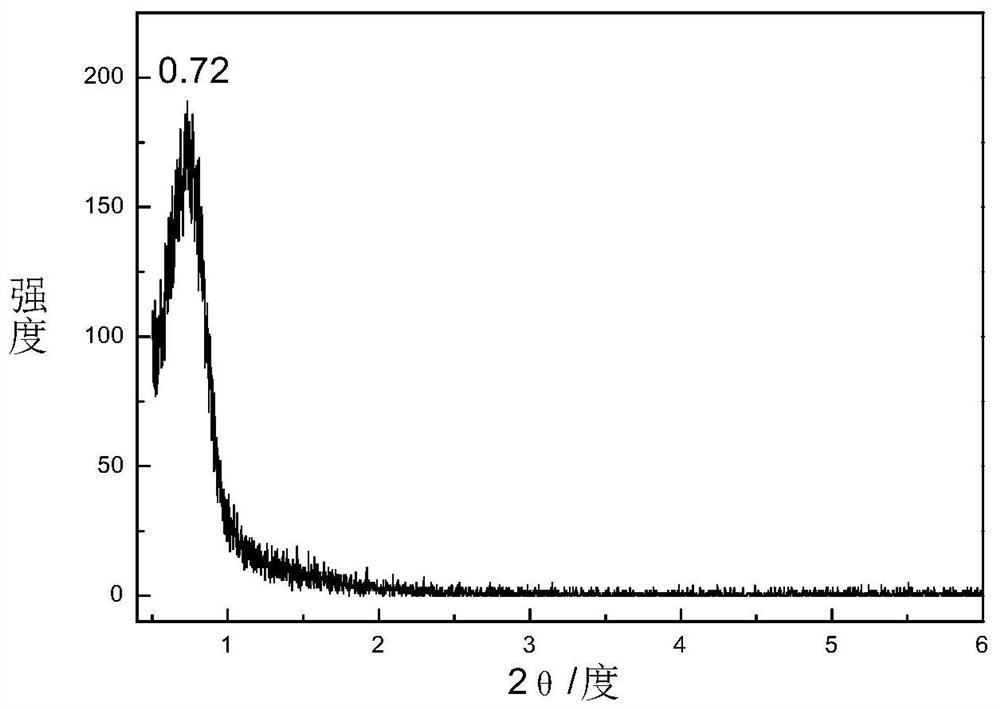

[0033] 1. Preparation of magnesium aluminum nitrate hydrotalcite by ion exchange method

[0034] 1) 0.09mol of solid powder Mg(NO 3 ) 2 ·6H 2 O and 0.045mol of solid powder Al(NO 3 ) 3 9H 2 O and 0.54mol solid urea were dissolved in 300ml to remove CO 2 In deionized water, stirred and transferred to a polytetrafluoroethylene reactor, crystallized at 120°C for 12 hours, then taken out, centrifugally washed with deionized water until neutral, and fully dried at 60°C to obtain magnesium aluminum carbonate hydrotalcite.

[0035] 2) Take the above-mentioned carbonate hydrotalcite 0.625g and solid NaNO 3 127g dissolved in 500ml to remove CO 2Add 0.25ml of concentrated nitric acid after uniform dispersion in deionized water, under the protection of nitrogen atmosphere, mechanically stir at room temperature for 24 hours, centrifugally wash with deionized...

Embodiment 2

[0050] Cadmium telluride quantum dots-silk protein and hydrotalcite composite luminescent film, the steps are as follows:

[0051] 1. Same as embodiment 1

[0052] 2. Same as embodiment 1

[0053] 3. Same as embodiment 1

[0054] 4. Transformation of β-sheet silk protein structure

[0055] Take the C solution of silk protein prepared in Example 1, add 70% volume concentration of ethanol solvent for treatment, the volume ratio of C solution of silk protein and ethanol solvent is 3:7, and the silk protein solution of random curl can be transformed into Form the secondary structure of β sheet, denoted as solution D;

[0056] 5. Preparation of cadmium telluride quantum dots-silk protein and hydrotalcite composite luminescent film

[0057] 1) Soak the quartz plate in concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 for 30 minutes, then alternately wash twice with ethanol and ultrapure water, and then alternately soak and pre-assemble with PDDA and PSS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com