Waterborne paint composition, preparation method and application thereof

A technology of water-based coatings and compositions, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems that the gloss is difficult to reach the same level as solvent-based, unfavorable for large-scale construction, low gloss of the coating film, etc., to achieve excellent appearance and low price Moderate, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] (1) Evenly mix the following components with a mixer: (The following components are all calculated in parts by weight)

[0095]

[0096] (2) Then use a sand mill to perform sanding until the fineness is below 10um, and add the following components:

[0097]

[0098] The above components are mixed evenly at high speed as component A.

[0099] (3) Evenly mix the following components with a mixer:

[0100] 20.0 parts of propylene glycol diacetate,

[0101] Bayhydur XP 2655 modified polyurethane curing agent 80.0 parts,

[0102] Stir well to obtain component B.

[0103] The A component and the B component are respectively sealed and packaged in a packaging tank for later use to obtain the water-based coating composition and avoid being exposed to the air.

[0104] The A component and the B component are mixed in a ratio of 100:24 parts by weight, and the coating is obtained after coating and crosslinking.

[0105] The mixing ratio of the A component and the B component is selected accord...

Embodiment 2

[0107] (1) Evenly mix the following components with a mixer: (The following components are all calculated in parts by weight)

[0108]

[0109] (2) Then use a sand mill to perform sanding until the fineness is below 10um, and add the following components:

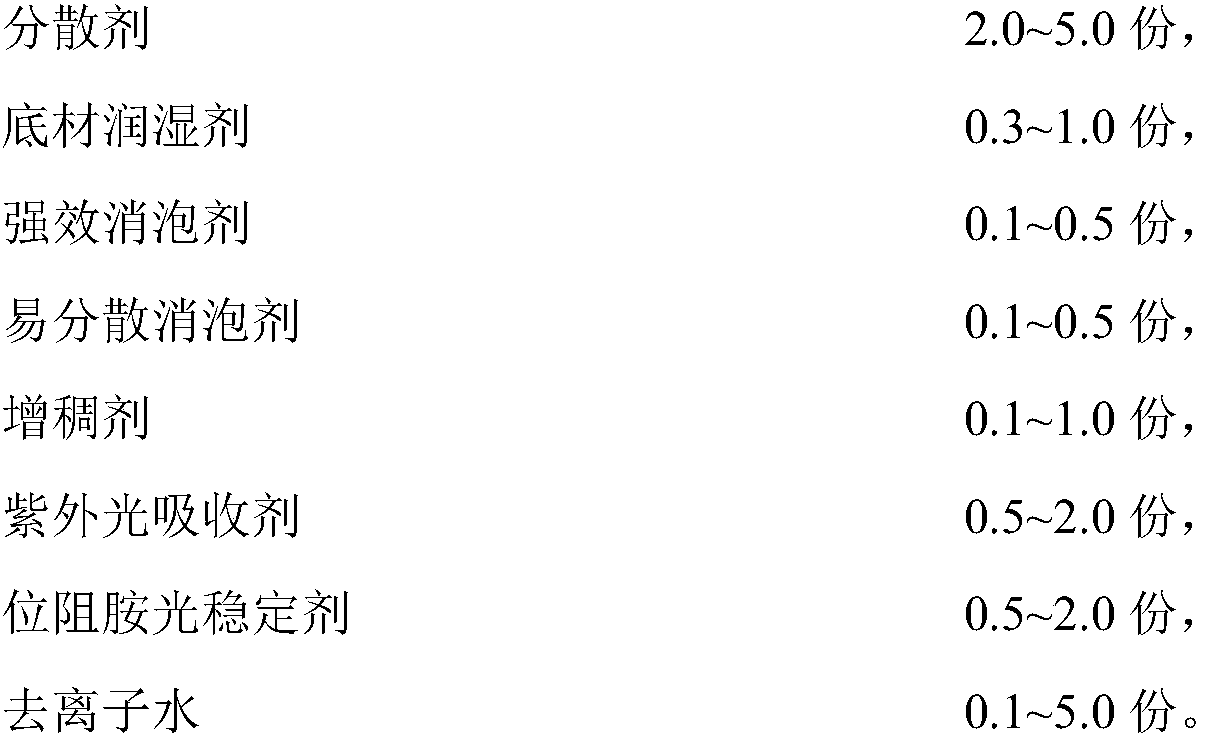

[0110]

[0111] The above components are mixed evenly at high speed as component A.

[0112] (3) Evenly mix the following components with a mixer:

[0113] 20.0 parts of propylene glycol diacetate,

[0114] Bayhydur XP 2655 modified polyurethane curing agent 80.0 parts,

[0115] Stir well to obtain component B.

[0116] The A component and the B component are respectively sealed and packaged in a packaging tank for later use to obtain the water-based coating composition and avoid being exposed to the air.

[0117] The A component and the B component are mixed in a ratio of 100:21 parts by weight, and the coating is obtained after coating and crosslinking.

[0118] The mixing ratio of the A component and the B component is selected as A:B...

Embodiment 3

[0120] (1) Evenly mix the following components with a mixer: (The following components are all calculated in parts by weight)

[0121]

[0122] (2) Then use a sand mill to perform sanding until the fineness is below 10um, and add the following components:

[0123]

[0124] The above components are mixed evenly at high speed as component A.

[0125] (3) Evenly mix the following components with a mixer:

[0126] 20.0 parts of propylene glycol diacetate,

[0127] Bayhydur XP 2655 modified polyurethane curing agent 80.0 parts,

[0128] Stir well to obtain component B.

[0129] The A component and the B component are respectively sealed and packaged in a packaging tank for later use to obtain the water-based coating composition and avoid being exposed to the air.

[0130] The A component and the B component are mixed in a ratio of 100:17.5 parts by weight, and the coating is obtained after coating and crosslinking.

[0131] The mixing ratio of the A component and the B component is selected acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com