Dredging system for offshore deepwater laid gravel bed surface and dredging vessel

一种碎石、深水的技术,应用在水利工程、特殊用途船只、人工岛等方向,能够解决难高效清除淤泥等问题,达到清淤效果好、结构简单、提高工作效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

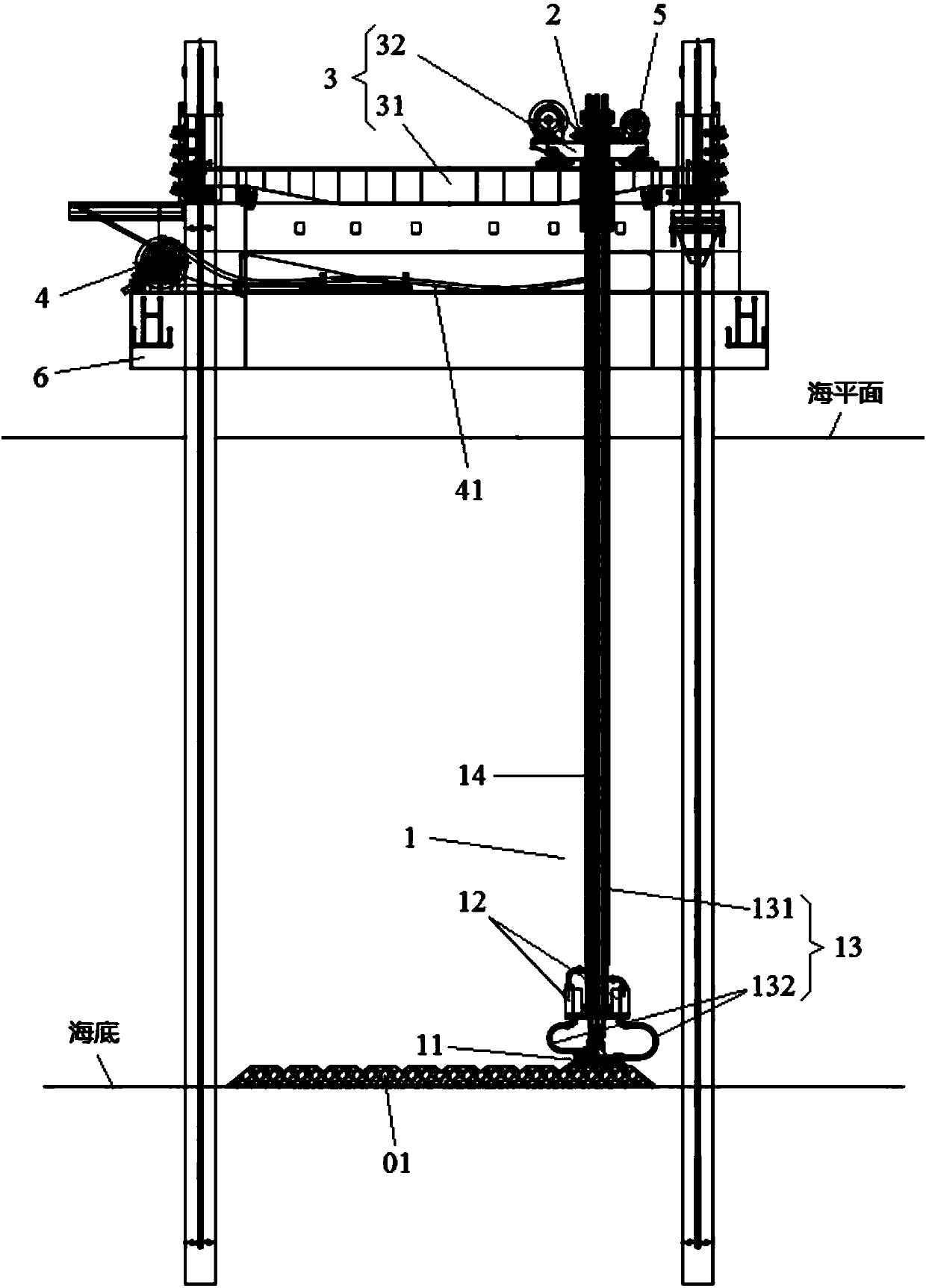

[0048] Such as Figure 1-2 As shown, the open sea deep water of the present invention is first paved with crushed stone bed surface dredging system, comprising:

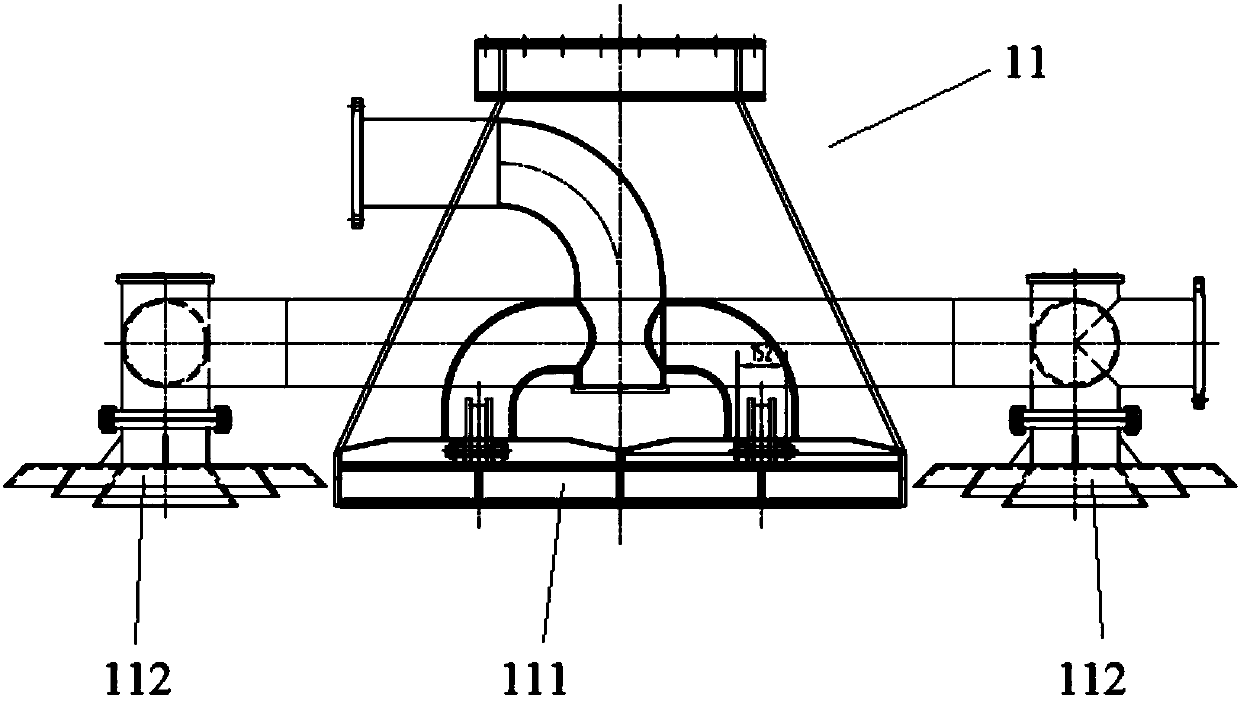

[0049] The dredging mechanism 1 includes a dredging suction head 11, a power component 12 and a dredging pipeline 13, the dredging suction head 11 is connected to the dredging pipeline 13, and the dredging pipeline 13 is connected to the power component 12, so The dredging suction head 11 includes at least one ridge surface suction port 111 and at least one ridge surface suction port 112, the opening ends of all the ridge surface suction ports 112 are lower than the opening ends of all the ridge surface suction ports 111, each of the ridge surface The suction port 111 is used to suck the silt at the top surface of each crushed stone ridge on the crushed stone bed surface 01, and each of the ditch suction ports 112 is used to suck two adjacent crushed stones on the crushed stone bed surface 01 Silt in furrows between...

Embodiment 2

[0058] Such as Figure 1-2 As shown, the dredging ship of the present invention includes a hull 6, a moon pool is provided on the hull 6, and the gravel bed surface dredging of the open sea deep water as described in Embodiment 1 is set on the hull 6. system, the dredging suction head 11 moves within the range of the moon pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com