Method for determining content of impurity elements in highly-pure bismuth

A technology of impurity element and determination method, applied in the field of chemical testing, can solve the problems of cumbersome removal method of bismuth matrix, long analysis process, poor precision, etc., and achieve the effect of shortening analysis period, improving analysis efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

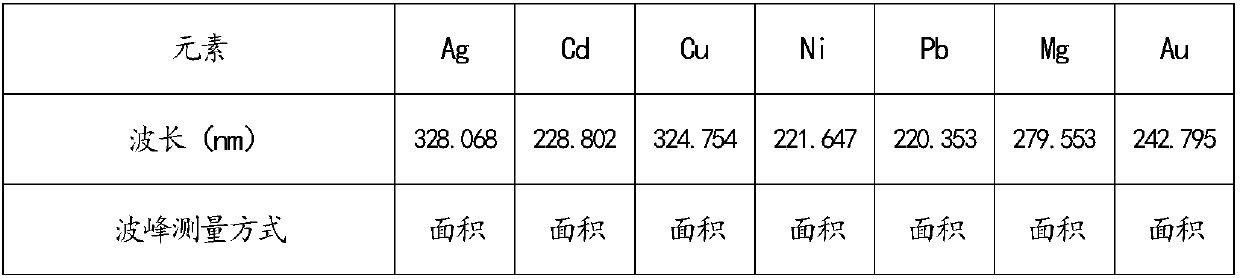

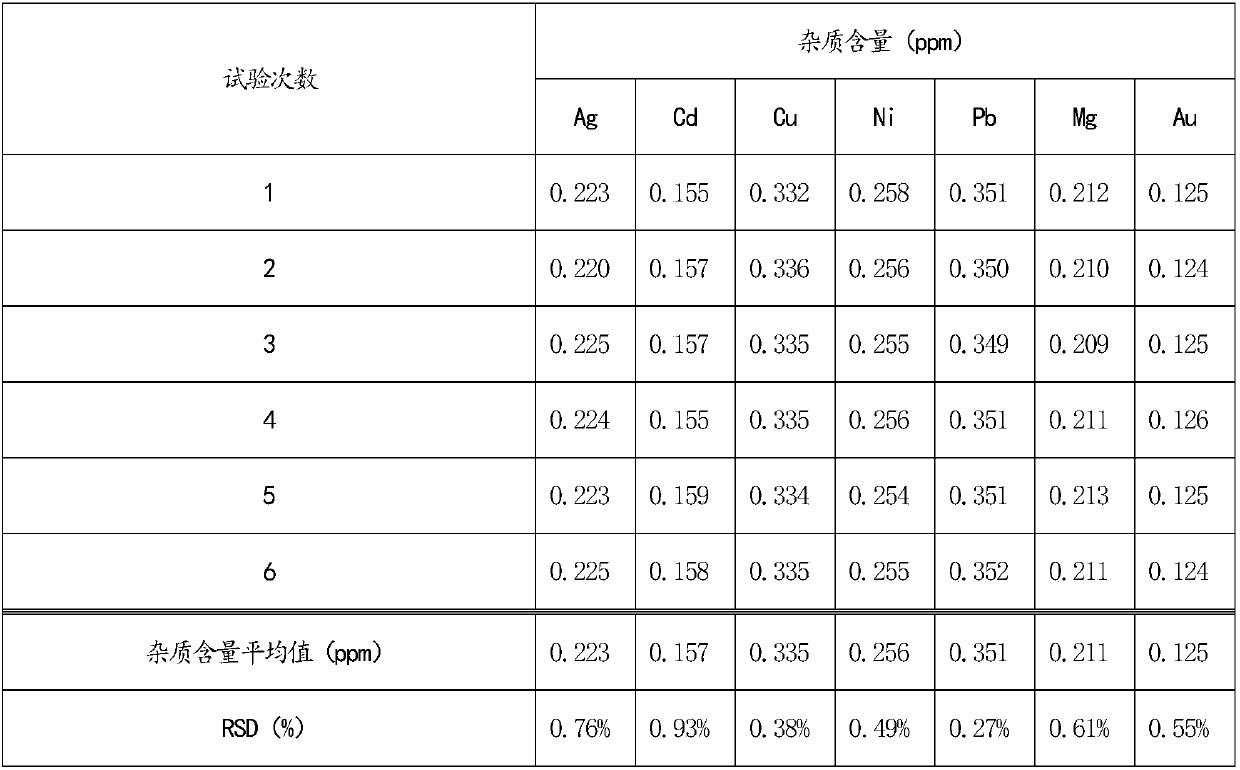

[0043] After the HCl gas of the present invention is volatilized to remove the bismuth main body, the content of impurity elements in the high-purity bismuth product Bi-05 is detected by the ICP-OES method, specifically:

[0044]Weigh 3.000 grams of sample to the nearest 0.001 grams. Measure the blank amount of impurity elements along with the sample. Put the sample in a quartz crucible, heat it, add 4-6ml of nitric acid dropwise to dissolve, heat to evaporate, add hydrochloric acid dropwise to dissolve to obtain the test solution. Put the crucible containing the test solution in the volatilization chamber, connect the device, start the jet pump, turn on the electricity to heat, turn the dropping funnel piston at about 200°C, add hydrochloric acid dropwise to the sulfuric acid in the flat bottom flask, and generate hydrogen chloride at a continuous and countable speed of bubbles The gas reacts with the test solution, keeps at 280±30°C to volatilize and remove bismuth trichlor...

Embodiment 2

[0049] After adopting the HCl gas of the present invention to volatilize and remove the bismuth main body, the content of impurity elements in the high-purity bismuth product Bi-06 is detected by the ICP-OES method, specifically:

[0050] Weigh 3.000 grams of sample to the nearest 0.001 grams. Measure the blank amount of impurity elements along with the sample. Put the sample in a quartz crucible, heat at low temperature, add 4-6ml of nitric acid dropwise to dissolve, heat to evaporate, add hydrochloric acid dropwise to dissolve to obtain the test solution. Put the crucible containing the test solution in the volatilization chamber, connect the device, start the jet pump, turn on the electricity to heat, turn the dropping funnel piston at about 200°C, add hydrochloric acid dropwise to the sulfuric acid in the flat bottom flask, and generate hydrogen chloride at a continuous and countable speed of bubbles The gas reacts with the test solution, keeps at 280±30°C to volatilize a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com