A kind of dry etching equipment

A technology of dry etching and equipment, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of shortening the production and maintenance cycle of the process chamber, poor thermal conductivity and mechanical strength, and affecting product yield, so as to prolong production and maintenance The cycle and processing method are simplified, and the effect of saving production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

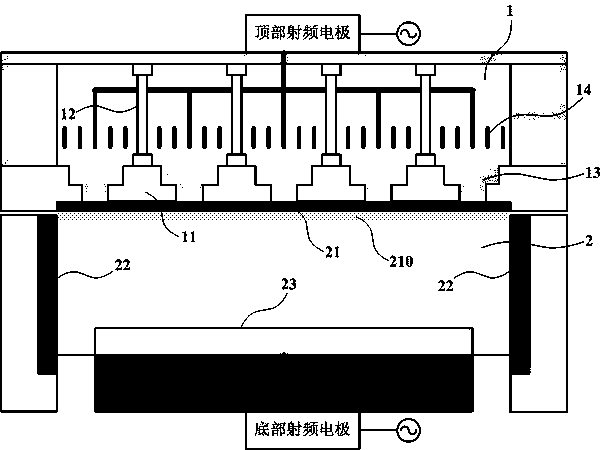

[0032] Please refer to figure 1 As shown, the embodiment of the present invention provides a dry etching equipment, including:

[0033] The process chamber formed by sealing the upper cavity 1 and the lower cavity 2 is used to perform various process reactions required for the dry etching process in the inductively coupled plasma mode;

[0034] The upper cavity 1 is provided with a plurality of skeletons 11 and suspension columns 12 for supporting the skeletons 11, and spaces are formed between the skeletons 11 for placing non-conductive dielectrics 13;

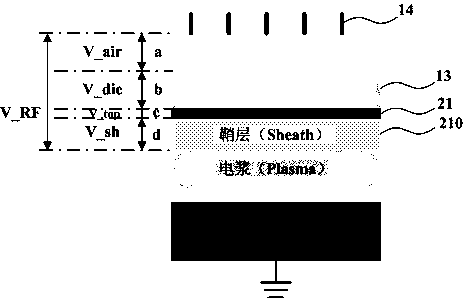

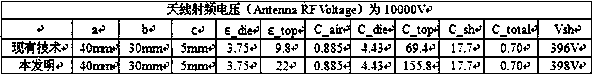

[0035] An antenna coil 14 is also arranged in the upper cavity 1 for forming an alternating current, and an alternating magnetic field or an electric field is induced by the alternating current and transmitted to the lower cavity 2 to form a high c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com