Porous carbon adsorbent and preparation method and application thereof

A porous carbon and adsorbent technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as difficult filtration and inconvenient adsorption of chromium ions, and achieve enhanced adsorption effect, Environmental protection, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare porous carbon adsorbent, the steps are as follows:

[0038] ①Put 1g of silica sand or glass fiber, 1g of glucose, 0.2g of sodium lauryl sulfate, 10mL of distilled water and 0.5mL of ethylenediamine into a 50ml reactor;

[0039] ②Put the reactor in an oven at 180°C for 8 hours;

[0040] ③After the reaction kettle drops to room temperature, filter the sample and dry it at 90°C;

[0041] ④Calcinate the sample at 700°C for 1h under nitrogen atmosphere;

[0042] ⑤ After the calcined sample was dehumidified for 7 days, soak it in 1.8wt% HCl solution for 1 hour, then wash it with distilled water, filter it, and dry it to form a porous carbon adsorbent.

[0043] After testing, the specific surface area of porous carbon silica sand is 10.042m 2 / g, the specific surface area of porous carbon glass fiber is 10.195m 2 / g, it can be seen that whether porous carbon is coated on silica sand or glass fiber has little effect on its specific surface area.

Embodiment 2

[0045] Prepare porous carbon adsorbent, the steps are as follows:

[0046] ①Put 1g of silica sand or glass fiber, 1g of glucose, 0.2g of sodium lauryl sulfate, 10mL of distilled water and 0.5mL of ethylenediamine into a 50ml reactor;

[0047] ②Put the reactor in an oven at 180°C for 8 hours;

[0048] ③After the reaction kettle drops to room temperature, filter the sample and dry it at 90°C;

[0049] ④Put the dried sample into 10ml of 10g / L KOH solution and evaporate to dryness in a drying oven;

[0050] ⑤ The evaporated sample was calcined at 700°C for 1 hour under a nitrogen atmosphere;

[0051] ⑥ After the calcined sample was deliquified in air for 7 days, it was soaked in 1.8wt% HCl solution for 1 hour, then washed with distilled water, filtered, and dried to form a porous carbon adsorbent.

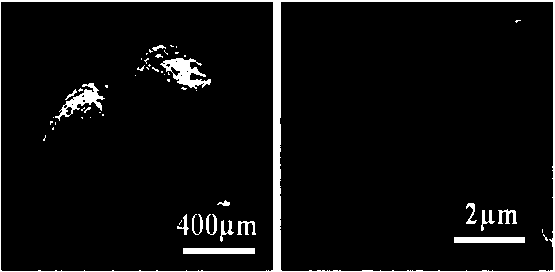

[0052] The SEM scanning figure of the obtained porous carbon adsorbent is as follows: figure 1 shown, from figure 1 (Left) It can be seen that porous carbon is better coated on th...

Embodiment 3

[0056] Prepare porous carbon adsorbent, the steps are as follows:

[0057] ①Put 1g of silica sand, 1g of glucose, 0.2g of sodium lauryl sulfate, 10mL of distilled water and 0.5mL of ethylenediamine into a 50ml reaction kettle;

[0058] ②Put the reactor in an oven at 180°C for 8 hours;

[0059] ③After the reaction kettle drops to room temperature, filter the sample and dry it at 90°C;

[0060] ④Put the dried sample into 10ml of 10g / L KOH solution and evaporate to dryness in a drying oven;

[0061] ⑤ The evaporated samples were calcined at 600°C, 700°C, 800°C, and 900°C for 1 hour under the protection of nitrogen atmosphere.

[0062] ⑥ After the calcined sample deliquesces in the air for 30 days, it is soaked in 1.8wt% HCl solution for 1 hour, then washed with distilled water, filtered, and dried to form a porous carbon adsorbent.

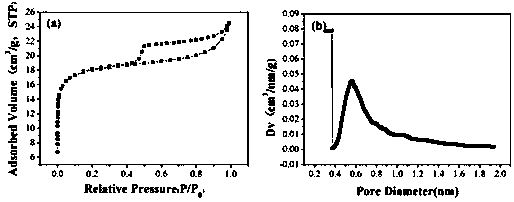

[0063] The specific surface area, pore volume and pore diameter of the product obtained are shown in Table 1 below, as can be seen from Table 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com