Preparation method of phosphorus-nitrogen co-doped biomass base porous carbon material for hexavalent chromium adsorption

A biomass and co-doping technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc. Low cost, easy industrial production, simple preparation steps and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

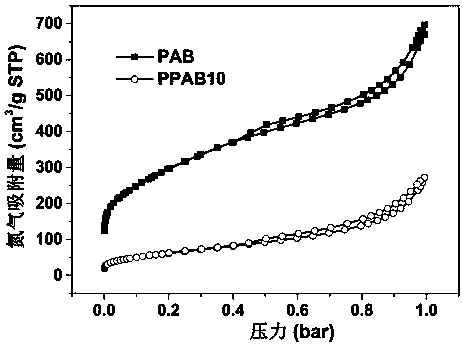

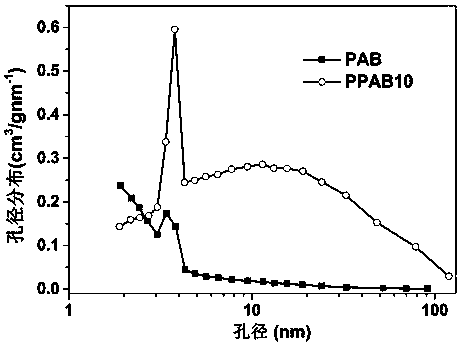

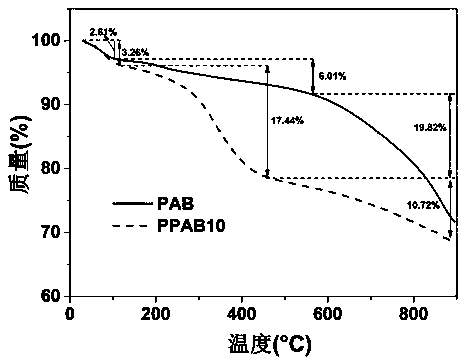

[0031] Mix the precursor porous carbon with the PEI solution at a mass volume ratio of 1g:5ml, then put the mixed solution into a shaker, shake at 160rpm at 30°C for 24 hours; then add 1% glutaraldehyde solution, and continue to It was shaken for 30 minutes under the same conditions; after fully washing with deionized water, it was dried at 80 °C for 12 hours, and named as PPAB10. Table 1 lists the performance parameters of Example 1.

[0032] PPAB10 performance parameter in the embodiment 1 of table 1

[0033]

Embodiment 2

[0035] Using the preparation conditions of Example 1, the difference is that the mass volume ratio of the precursor porous carbon to PEI is 1g:0.5ml, and then add a 0.1% concentration of glutaraldehyde solution, then wash with deionized water, dry, and name it PPAB1 . Table 2 lists the performance parameters of Example 2.

[0036] PPAB1 performance parameter in the embodiment 2 of table 2

[0037]

Embodiment 3

[0039] Using the preparation conditions of Example 1, the difference is that the mass volume ratio of the precursor porous carbon to polyethyleneimine is 1g:1ml, and then add a 0.2% glutaraldehyde solution correspondingly, then wash with deionized water, dry, and name for PPAB2. Table 3 lists the performance parameters of Example 3.

[0040] PPAB2 performance parameter among the table 3 embodiment 3

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com