Fireproof and heat-insulating glass and preparation method thereof

A heat-insulating glass and glass technology, applied in the field of special glass, can solve the problems of short fire prevention time, easy melting or ashing, easy self-explosion, etc., and achieve good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of this nano silicon dioxide potassium water glass glue, specifically is:

[0039] In parts by weight, add 0.2-1.0 parts of dispersant, 50-70 parts of nano-silica, and 0.2-0.8 parts of polyethylene glycol to 68-100 parts of deionized water, stir well and then add 18-48 parts of 50wt % potassium hydroxide solution, heat and stir until the solution is transparent, finally add 0.5-2.0 parts of sodium fluorosilicate and continue stirring for 10-40min, cool to room temperature, pour into a sealed container and vacuum until the solution no longer has bubbles , the resulting solution is nano silica potassium water glass glue; the dispersant can be one or more of sodium hexametaphosphate, acrylamide and sodium tripolyphosphate; polyethylene glycol can be selected from PEG400-PEG8000 poly Ethylene glycol, such as one or more of PEG2000, PEG400, PEG4000, PEG8000; the particle size of nano-silica is 1-100nm.

Embodiment 1

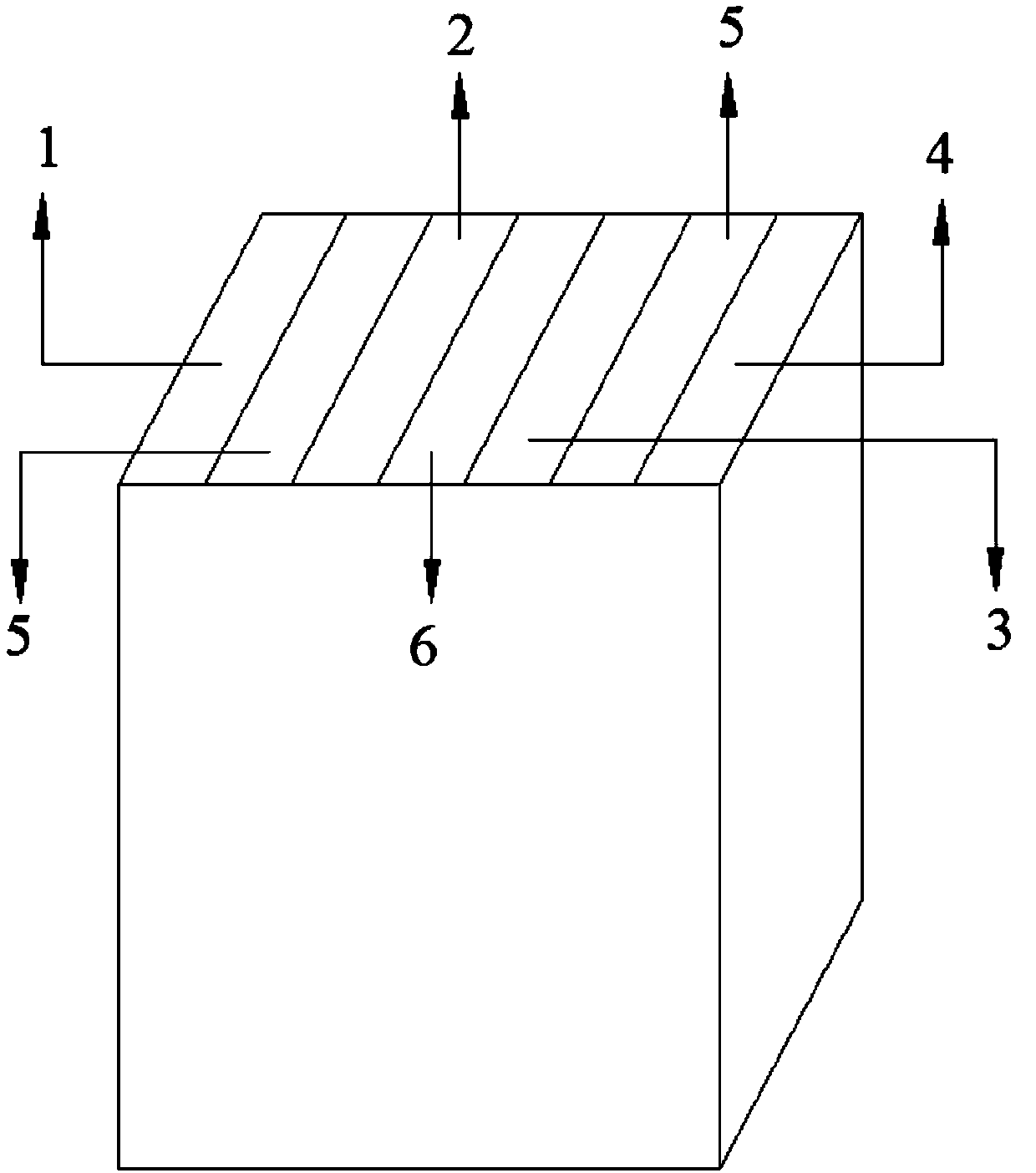

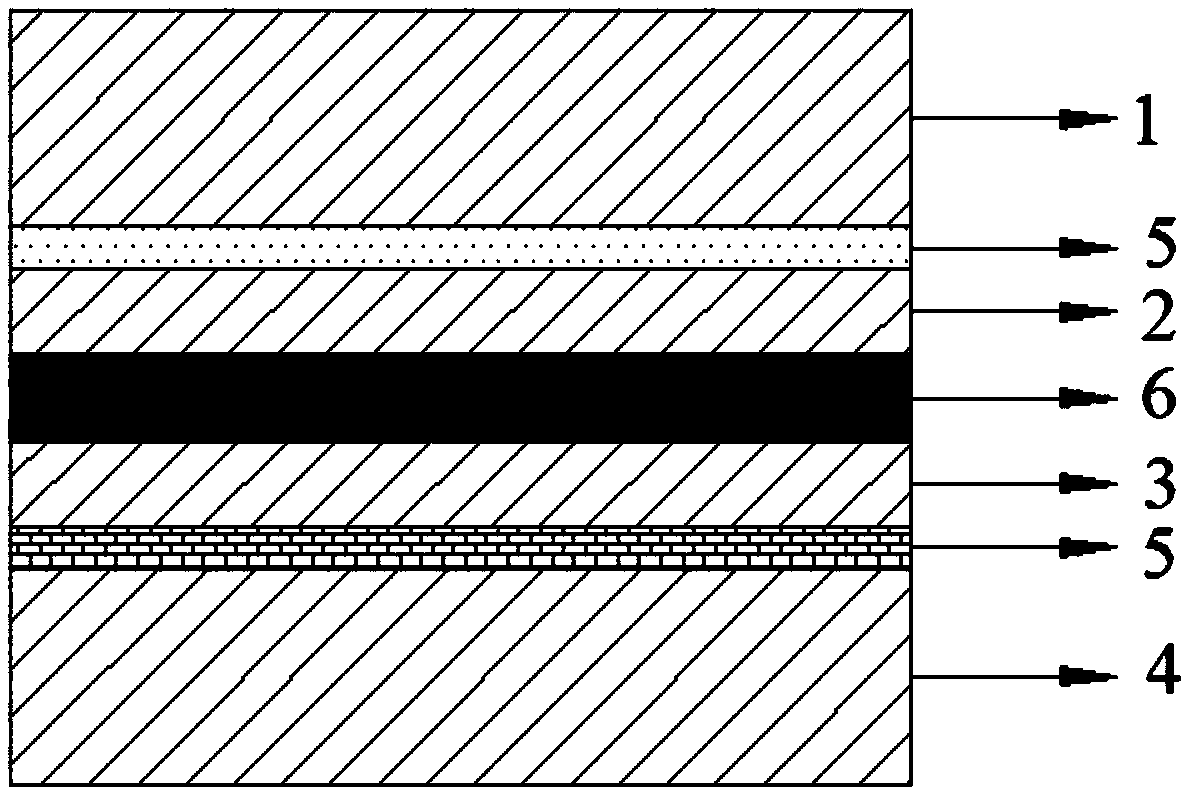

[0041] The fire-proof and heat-insulating glass of this embodiment, such as figure 2 As shown, from top to bottom are surface glass layer 1, vacuum layer 5, inner glass layer 2, fireproof adhesive layer 6, inner glass layer 3, vacuum layer 5, and bottom glass layer 4. Wherein, both the bottom glass layer 4 and the surface glass layer 1 are glass-ceramics with a thickness of 4 mm, the thickness of the vacuum layer 5 is 1.0 mm, and the inner glass layer 2 and the inner glass layer 3 are all coated with Low-E glass with a thickness of 3 mm. The tempered glass of the film, the fireproof adhesive layer is nano silica potassium water glass with a thickness of 2mm and a number of m of 6. Tested with the GB15763.1-2009 standard (this standard is used in the examples and comparative examples), the fire resistance limit of this fireproof and heat insulating glass is ≥ 3h.

Embodiment 2

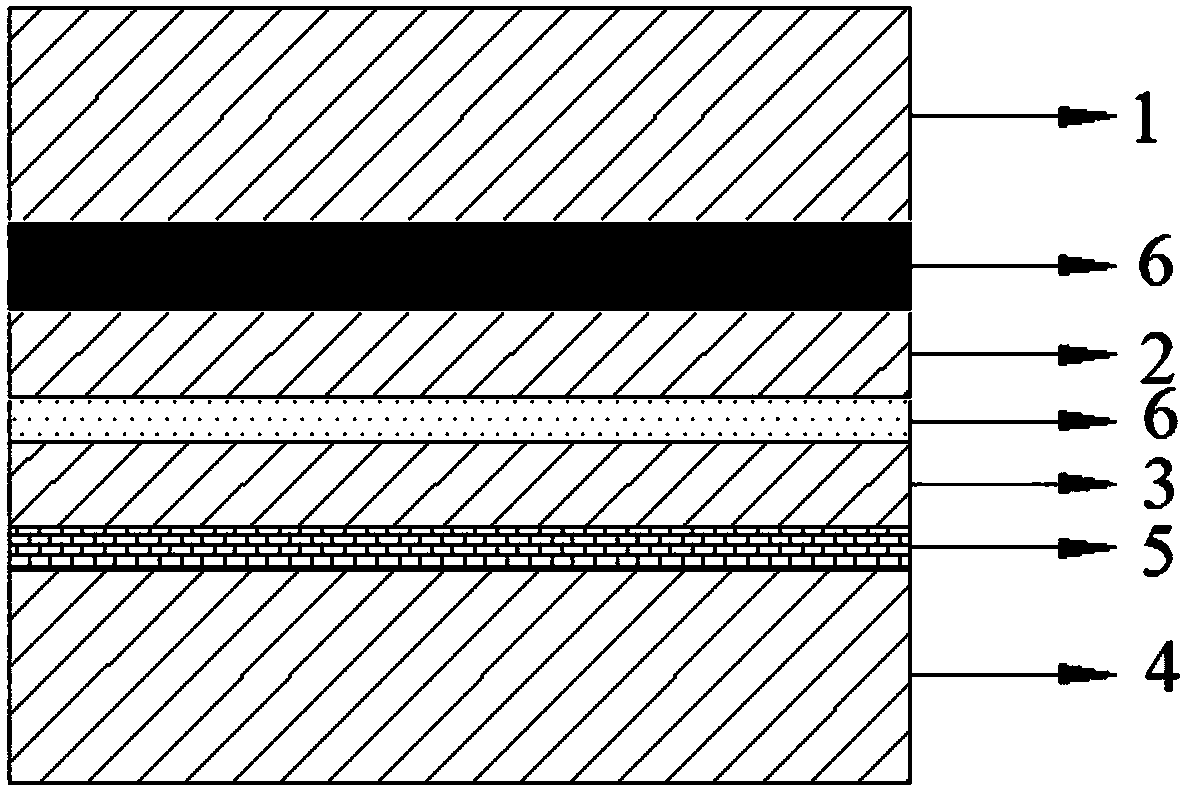

[0043] The fire-proof and heat-insulating glass of this embodiment, such as image 3 As shown, from top to bottom are surface glass layer 1, fireproof adhesive layer 6, inner glass layer 2, fireproof adhesive layer 6, inner glass layer 3, vacuum layer 5, and bottom glass layer 4. Wherein, the bottom glass layer 4 and the surface glass layer 1 are high borosilicate glass with a thickness of 3mm, the thickness of the vacuum layer is 0.5mm, and the inner glass layer 2 and the inner glass layer 3 are both soda lime silicate with a thickness of 3mm. For glass, the fireproof adhesive layer is nano-silicon dioxide potassium water glass with a thickness of 1mm and a number of m of 6. The fire resistance limit of this fireproof and heat insulating glass is ≥2.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com